Automatic absorption liquid filling and labeling integrated system

An integrated, liquid-absorbing technology, which is applied in labeling machines, liquid bottling, liquid handling, etc., can solve the problems of label attachment and difficulty in satisfying automation, and meet the requirements of automatic detection and improve the efficiency of liquid addition and labeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

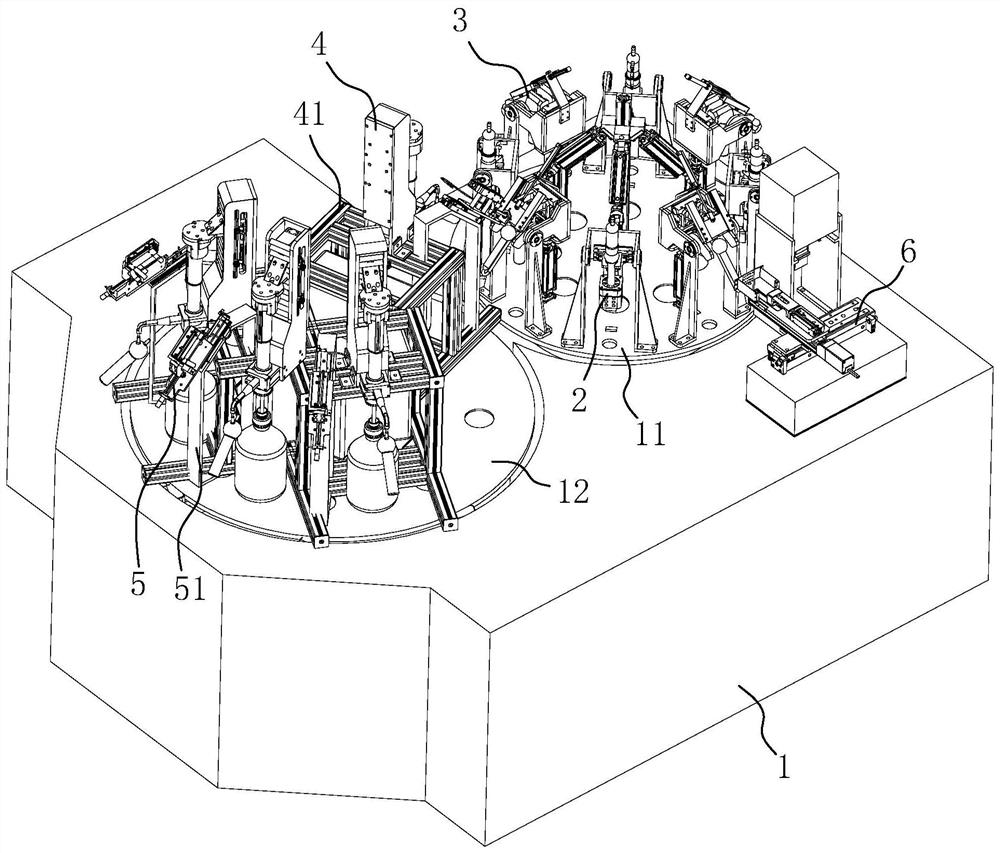

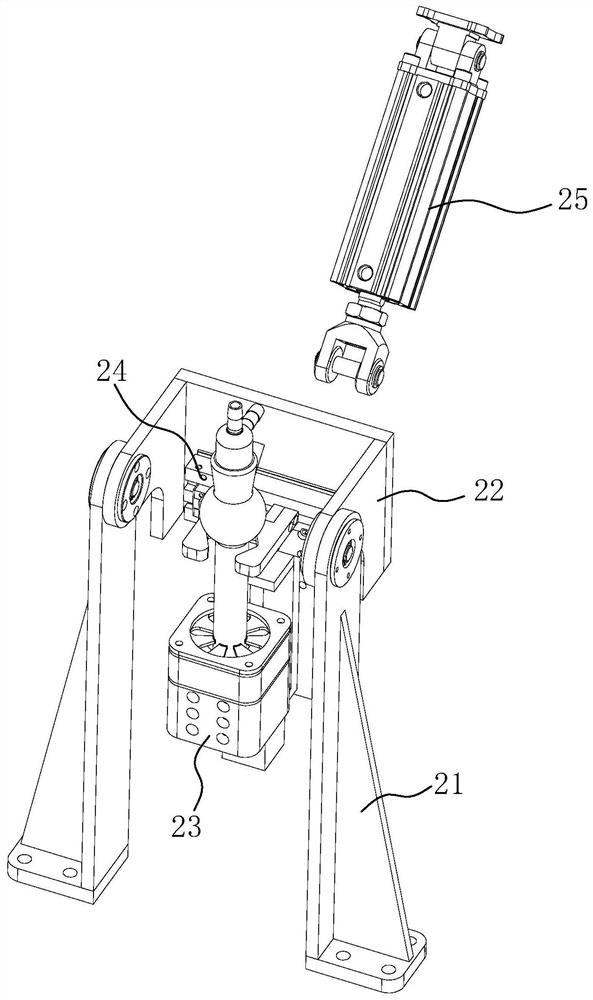

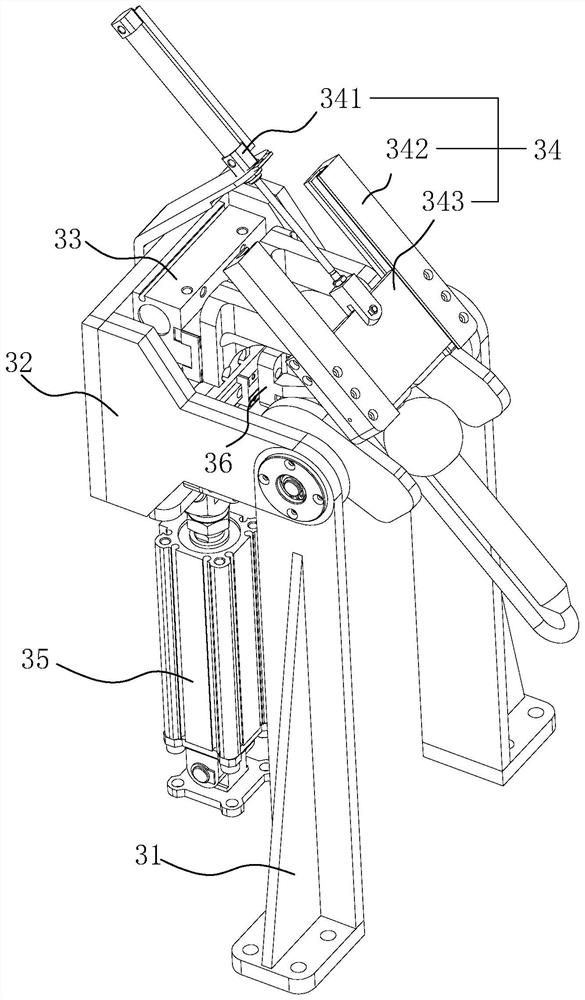

[0051] An automatic absorption liquid filling and labeling integrated system, such as Figure 1 to Figure 8 As shown, it includes: a working machine platform 1, which is rotatably connected with a first carrying tray 11 and a second carrying tray 12 oppositely arranged on the working machine platform 1, and the working machine platform 1 is provided with a drive for respectively driving the first carrying tray 11 and the second carrying tray 12. The first drive motor and the second drive motor that the second carrying tray 12 rotates; several spacer rings are arranged on the first carrying tray 11, the first clamping mechanism 2 and the second clamping mechanism for clamping the absorption bottle to be labeled 3. A number of spacer rings are arranged on the second carrying tray 12, and the first liquid filling mechanism 4 and the second liquid filling mechanism 5 corresponding to the first clamping mechanism 2 and the second clamping mechanism 3 respectively, the first carrying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com