Earthwork backfilling and tamping device under a ground beam and using method thereof

A technology of tamping device and ground beam, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc., and can solve the problems of surrounding soil loss and unsatisfactory backfilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

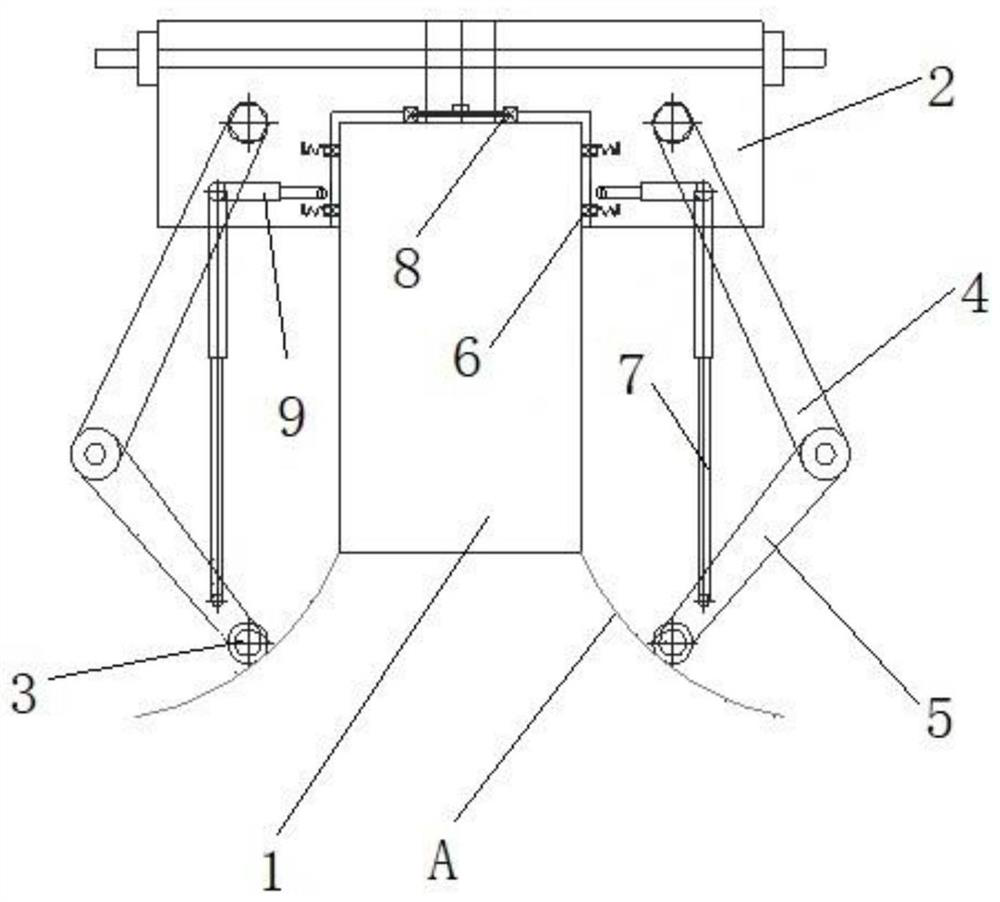

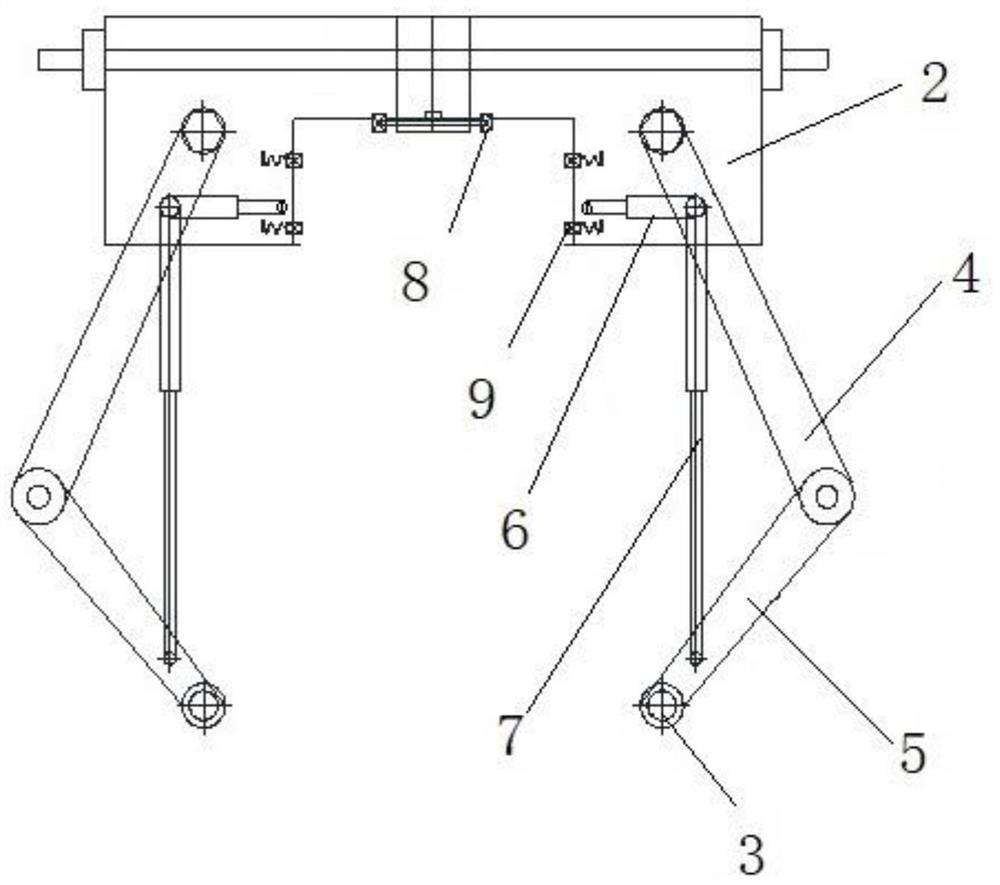

[0021] Such as figure 1 As shown, the present invention provides an earthwork backfill tamping device under a ground beam, which includes a briquetting block 2 fixed on the ground beam 1, and a traveling mechanism and an actuator are arranged on the briquetting block. The walking mechanism is set between the pressing block and the ground beam, and is used to move the pressing block installed on the bottom beam to a suitable position and fix it at this position; one end of the actuator is installed on the pressing block, and the other end acts on the ground backfilling The vibrating roller 3 is installed on the soil, and the trajectory A of the vibrating roller is set by the actuator, so that the vibrating roller reciprocates in the trajectory, thereby realizing the compaction of the backfill. In some embodiments, the earthwork backfilling and compacting devices under the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com