Method and device for improving temperature measurement precision

A temperature measurement and accuracy technology, applied in the field of improving temperature measurement accuracy, can solve the problems of data deviation, prone to temperature loss, increase wafer process damage rate, etc., to achieve zero temperature loss and improve temperature measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

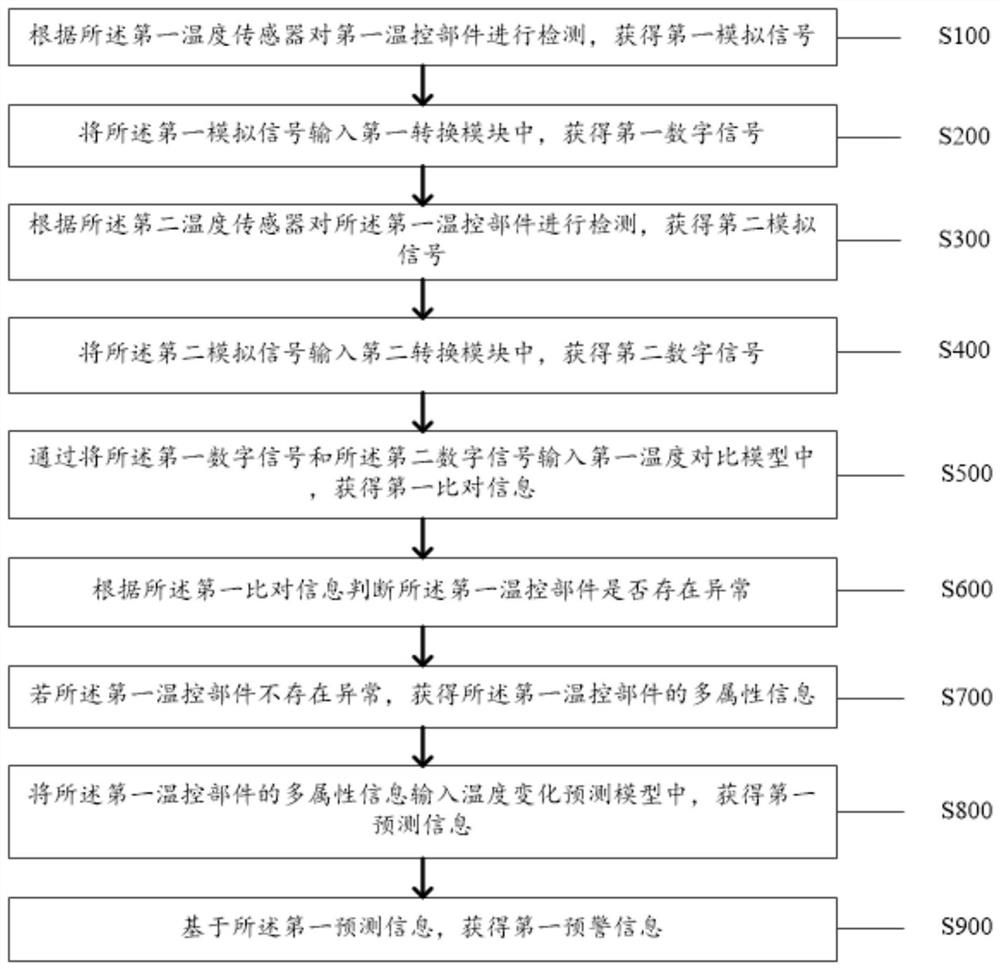

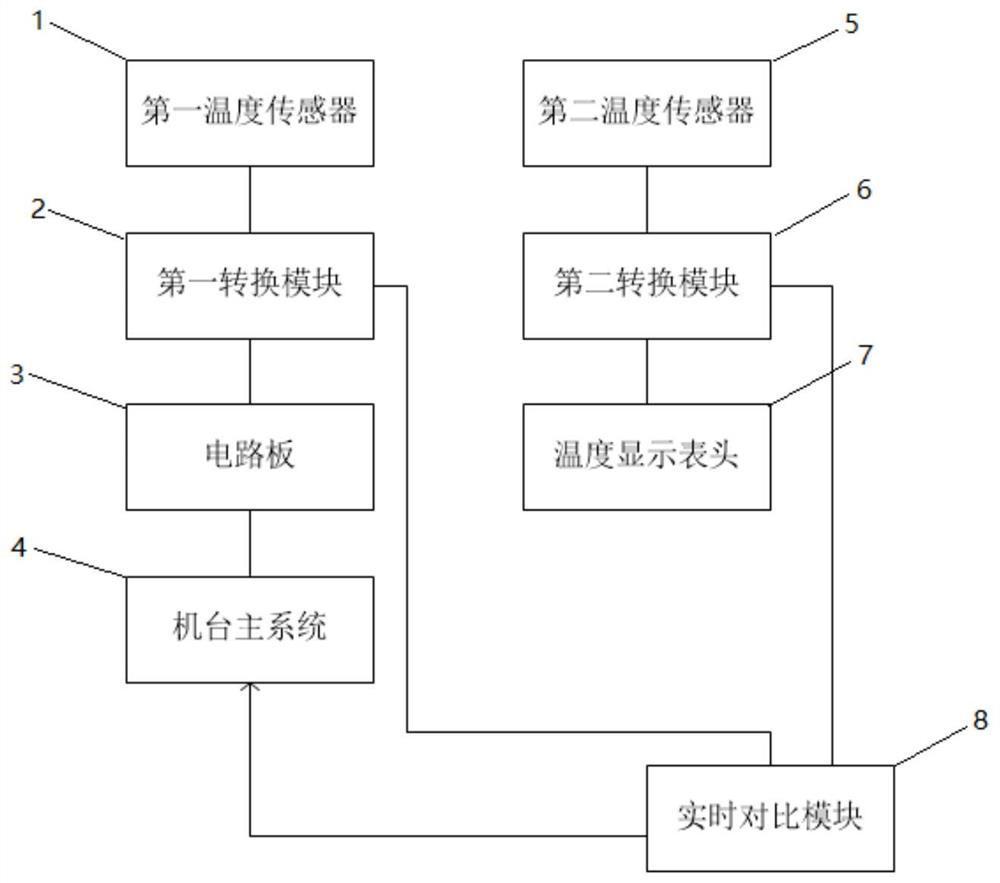

[0025] Such as figure 1 As shown, the embodiment of the present application provides a method for improving the accuracy of temperature measurement, wherein the method is applied to a device for improving the accuracy of temperature measurement, and the device is connected in communication with the first temperature sensor and the second temperature sensor, Such as figure 2 As shown, the method completes corresponding control based on the temperature comparison device structure, wherein the temperature comparison device structure includes a first temperature sensor 1, a first conversion module 2, a circuit board 3, a machine main system 4, and a second temperature sensor 5, the second conversion module 6, the temperature display meter head 7, and the real-time comparison module 8, the method includes:

[0026] Step S100: Detecting the first temperature control component according to the first temperature sensor to obtain a first analog signal;

[0027] Specifically, a tempe...

Embodiment S735

[0064] Further, the embodiment S735 of the present application also includes:

[0065] Step S7351: Obtain the first warning frequency in the first preset time period;

[0066] Step S7352: judging whether the first warning frequency is within the preset warning frequency threshold;

[0067] Step S7353: If the first warning frequency is not in the preset warning frequency, obtain a first collection instruction;

[0068] Step S7354: Analyze all early warning information according to the first collection instruction to obtain the first main influencing component;

[0069] Step S7355: Replace the first main influencing component according to the first replacement instruction.

[0070] Specifically, the first early warning frequency is the frequency of early warning when all the early warning information in the preset time is collected. Further, it is judged whether the frequency of the early warning is too abnormal or too frequent through the preset frequency early warning, and t...

Embodiment 2

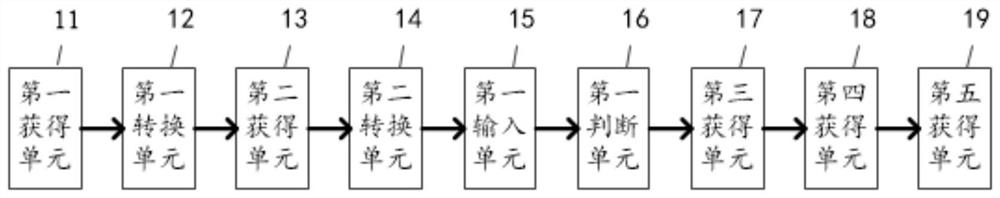

[0081] Based on the same inventive idea as a method for improving temperature measurement accuracy in the foregoing embodiments, the present invention also provides a device for improving temperature measurement accuracy, such as image 3 As shown, the device includes:

[0082] A first obtaining unit 11, the first obtaining unit 11 is configured to detect the first temperature control component according to the first temperature sensor, and obtain a first analog signal;

[0083] A first conversion unit 12, configured to input the first analog signal into a first conversion module to obtain a first digital signal;

[0084] A second obtaining unit 13, the second obtaining unit 13 is configured to detect the first temperature control component according to the second temperature sensor, and obtain a second analog signal;

[0085] A second conversion unit 14, configured to input the second analog signal into a second conversion module to obtain a second digital signal;

[0086] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap