High-speed train wheel set bearing weak fault diagnosis method and system

A fault diagnosis, train wheel technology, used in the testing of measuring devices, instruments, mechanical parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

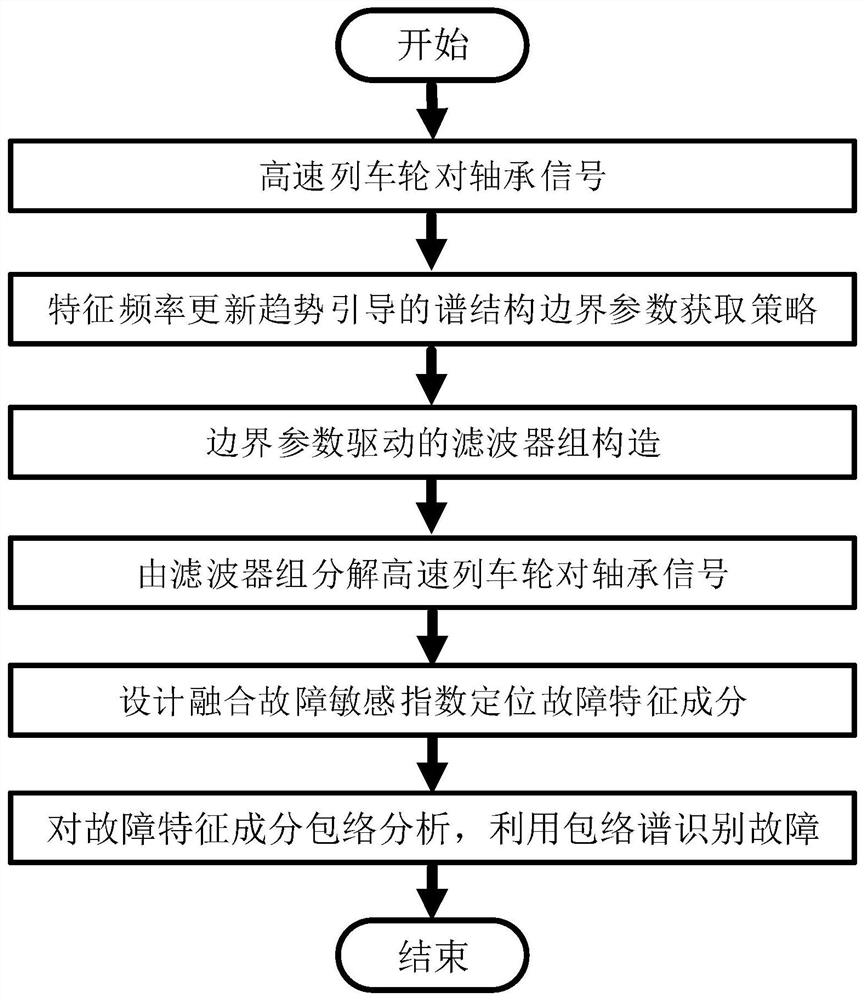

[0067] refer to figure 1 , the embodiment of the present invention provides a high-speed train wheel set bearing weak fault diagnosis method, comprising the following steps:

[0068] S1: Using the feature frequency update trend of the high-speed train wheel set bearing signal to construct a spectrum feature information scanner to obtain the boundary parameters of the potential feature components in the signal;

[0069] S2: Construct a filter bank according to the obtained boundary parameters, decompose the high-speed train wheel set bearing signal, and obtain the corresponding mode components;

[0070] S3: Establish the fusion fault sensitivity index, and locate the fault characteristic component by calculating the fault sensitivity index corresponding to the mode component;

[0071] S4: Perform envelope analysis on the fault feature components to obtain the envelope spectrum, detect weak fault features according to the envelope spectrum, and complete the weak fault diagnosis...

Embodiment 2

[0114] Based on the same inventive concept, this embodiment provides a high-speed train wheel-set bearing weak fault diagnosis system. The problem-solving principle is similar to that of the rail vehicle serial number identification method, and repeated descriptions will not be repeated.

[0115] A high-speed train wheel set bearing weak fault diagnosis system, including:

[0116] The boundary parameter acquisition module is used to construct a spectrum characteristic information scanner by using the characteristic frequency update trend of the high-speed train wheel-set bearing signal, and obtain the boundary parameters of potential characteristic components in the signal;

[0117] The decomposition module is used to construct a filter bank according to the obtained boundary parameters, and decompose the high-speed train wheel set bearing signal to obtain corresponding mode components;

[0118] The fault location module is used to establish the fusion fault sensitivity index,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com