Anti-explosion and anti-collision infrared touch all-in-one machine

An infrared touch and all-in-one machine technology, applied in the direction of supporting machines, mechanical equipment, machines/stands, etc., can solve the problems that the infrared touch all-in-one machine does not have an explosion-proof and anti-collision structure, and the infrared touch screen is damaged and broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

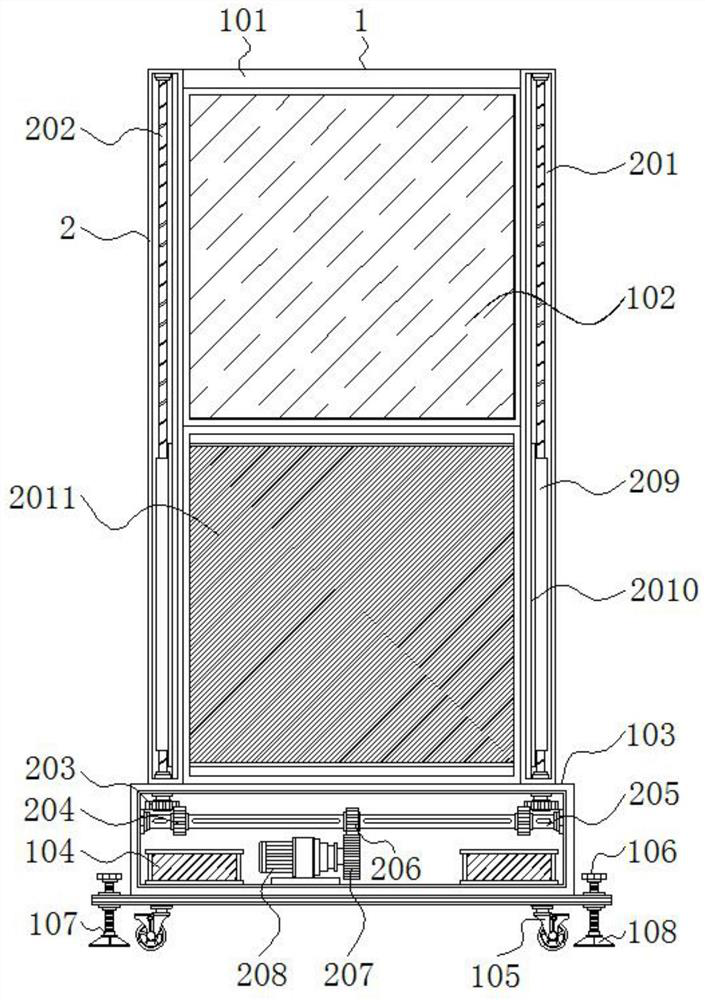

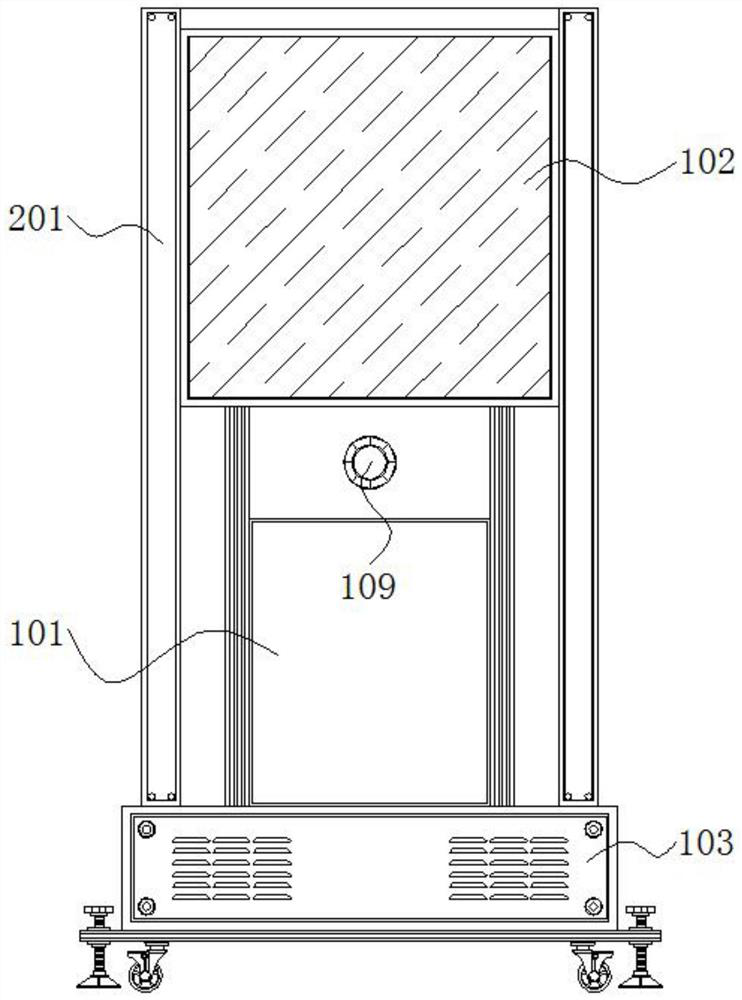

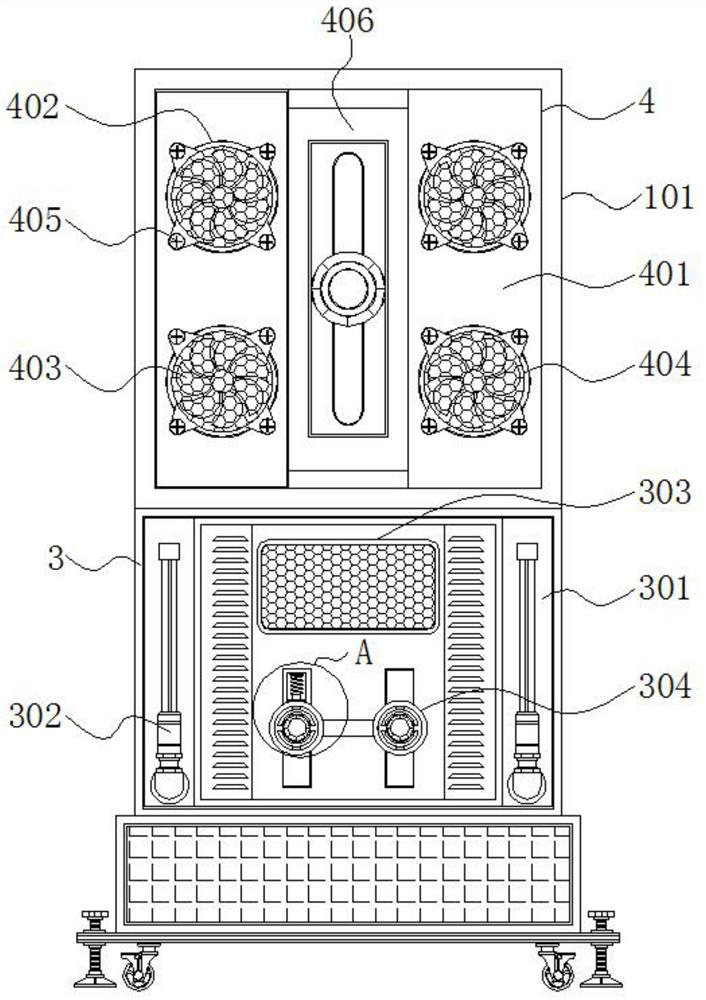

[0027] see Figure 1-5 , an explosion-proof and anti-collision infrared touch all-in-one machine, including a main body 1 and a transmission assembly 3, a protective assembly 2 is provided at the lower front end of the main body 1, and the protective assembly 2 includes a placement groove 201, a screw 202, and a screw gear 203 , connecting gear 204, connecting shaft 205, transmission gear 206, motor gear 207, servo motor 208, connecting sleeve 209, connecting block 2010 and protective baffle 2011, the inner side of the placement groove 201 is provided with a screw mandrel 202, and the inner side of the screw mandrel 202 The lower end is connected with a screw gear 203, the outer side of the screw gear 203 is connected with a connection gear 204, and the inner middle part of the connection gear 204 is connected with a connection shaft 205, and the outer middle part of the connection shaft 205 is provided with a transmission gear 206, and the transmission gear 206 The outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com