Anti-folding PE communication pipeline

A pipeline and anti-pressure technology, which is applied in the field of PE pipelines, can solve problems such as cable corrosion, communication signal interference, and reduction of internal space in pipelines, so as to improve the compression resistance, avoid mutual interference, and ensure the internal space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

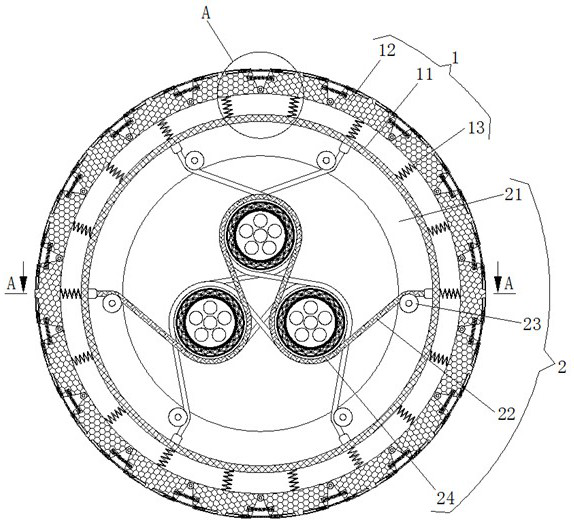

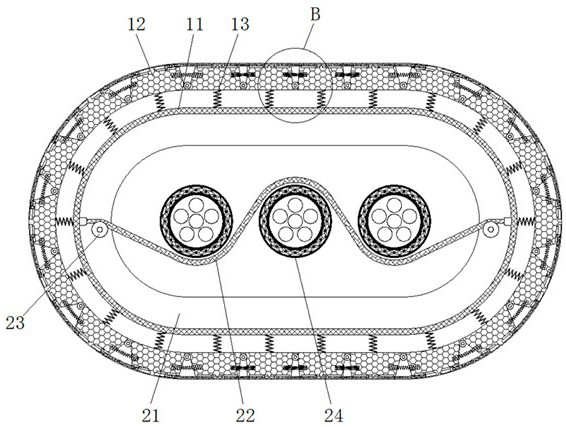

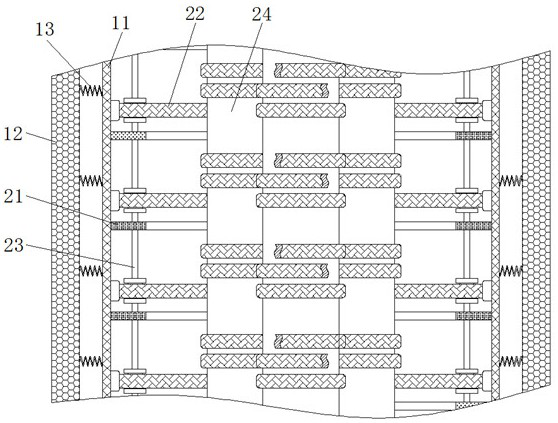

[0025] see Figure 1-5 , a kind of crush-proof PE communication pipe, comprising a pipe shell 1, the pipe shell 1 includes an inner shell 11 and an outer shell 12, a spring 13 is fixedly connected between the inner shell 11 and the outer shell 12, and the outer shell 12 is provided with Notches 14, the inner sides of the notches 14 between the shells 12 are hinged to each other, and the notches 14 are triangular in shape, and the opening gradually increases from the inside to the outside, so that the shells 12 can be opened and closed relatively at the notches 14, and the notches 14 inside the shells 12 There is a seal 15 slidingly connected between the gaps 14, and a spring 16 is fixedly connected to the inner side of the seal 15 between the gaps 14. Through the design of the gap 14 outside the shell 12 of the pipeline housing 1, when the pipeline is under pressure, the gap 14 on the force-bearing surface can be closed. Shrink instead of unfolding on the force-bearing surface...

Embodiment 2

[0027] see Figure 1-6 , a crush-proof PE communication pipe, comprising a pipe shell 1, a traction mechanism 2 is arranged inside the pipe shell 1, the traction mechanism 2 includes a partition 21, and a rubber strip 22 is fixedly connected to the inside of the partition 21, and the partition One side of the rubber strip 22 between the plates 21 is rotatably connected with a roller 23. There are threading pipes 24 passing through the rubber strips 22. There are three threading pipes 24, which are located inside the pipe shell 1 and are wrapped with rubber strips on the periphery. 22. There are three rubber strips 22 between the two partitions 21, respectively bypassing one of the three threading pipes 24, and passing through the other two threading pipes 24 to both sides, and connecting with the pipe shell 1 The two ends of the inner wall are fixedly connected, and the three rubber strips 22 are distributed forward and backward. Through the design of the internal traction mec...

Embodiment 3

[0029] see Figure 1-6 , a crush-proof PE communication pipe, comprising a pipe shell 1, the pipe shell 1 includes an inner shell 11 and an outer shell 12, a spring 13 is fixedly connected between the inner shell 11 and the outer shell 12, and the material of the inner shell 11 is Soft rubber, and the two ends of the rubber strip 22 are fixedly connected on the inner wall of the inner shell 11, the partition plate 21 is annular, the material is the same as the inner shell 11, and is fixedly connected with the inner wall of the inner shell 11, so that the inner shell 11 can carry out Plastic deformation, and in the process of deformation, it will drive the rubber strip 22 to move accordingly. There is a gap 14 on the outside of the shell 12, and the inner sides of the gap 14 between the shells 12 are hinged with each other, and the gap 14 is triangular, from inside to outside The opening gradually increases, so that the shell 12 can be opened and closed relatively at the notch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com