Label detection method and device based on double sensors and handheld thermal printing head

A label detection, dual-sensor technology, applied in printing devices, printing, typewriters, etc., can solve problems such as paper detection errors and label learning failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

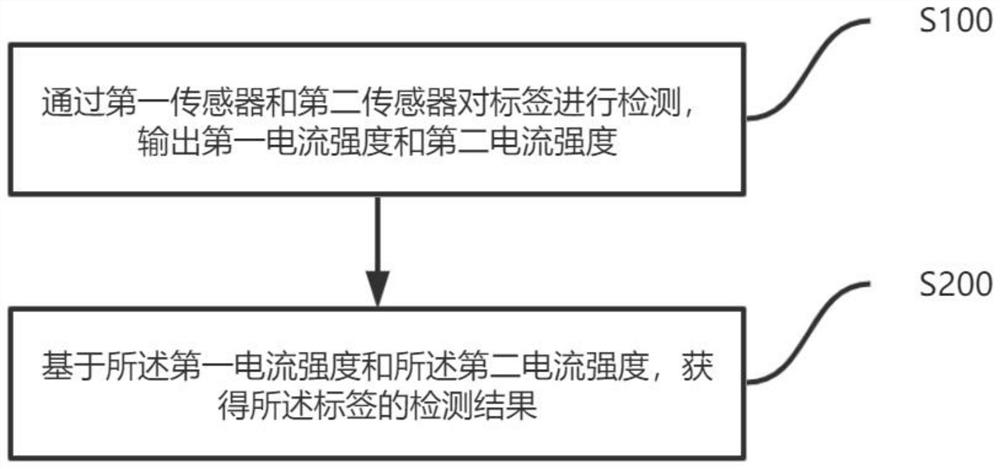

[0054] The present invention provides an embodiment of a label detection method based on dual sensors, such as figure 1 shown, including:

[0055] S100 Detecting the label through the first sensor and the second sensor, and outputting the first current intensity and the second current intensity.

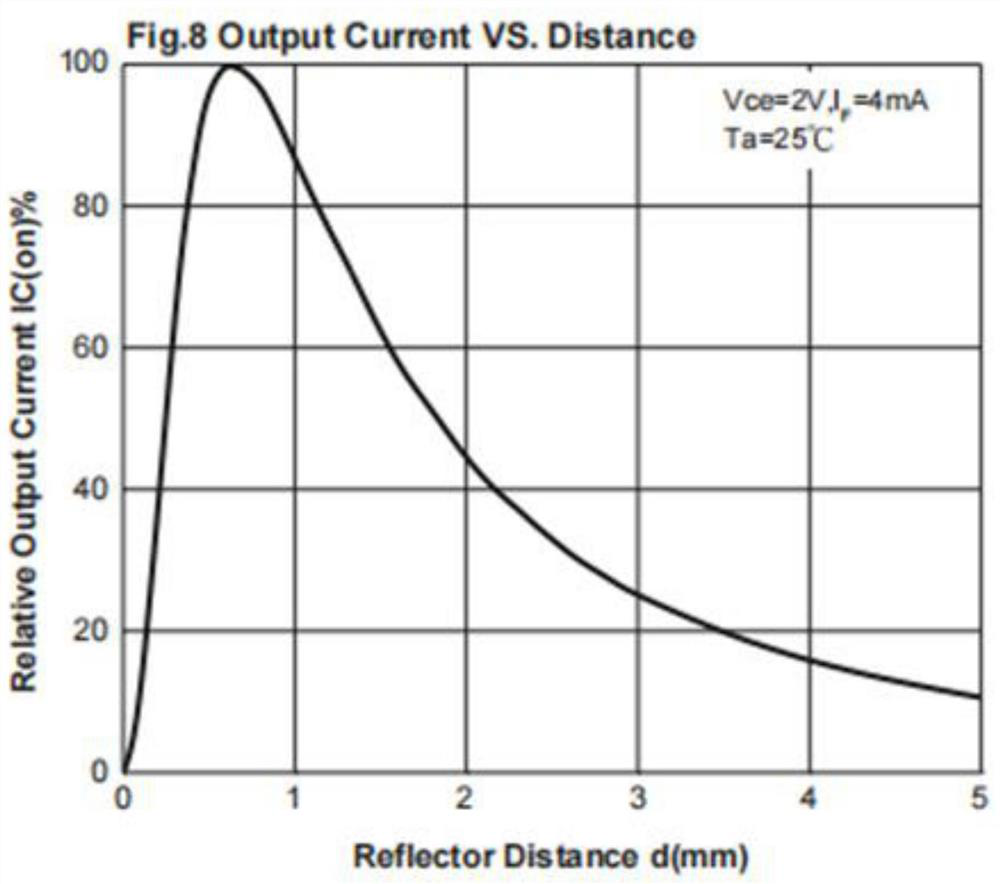

[0056] Specifically, such as figure 2 as shown, figure 2 It is a graph of the output current intensity of this type of sensor and the paper distance, which can be obtained from figure 2 It is observed that the distance fluctuation of 0.1mm will affect the output current of the sensor by nearly 20%, so the sensor is very sensitive to the paper distance.

[0057] In this embodiment, through a series of historical data, it is verified that the sensor output current has a linear relationship with the distance from the distance of 0mm to about 0.7mm, and this gap can just cover the conventional pressboard and sensor. Gap (the gap in which the paper floats).

[0058] The paper, that ...

Embodiment 2

[0062] Based on the above-mentioned embodiment, the parts that are the same as those in the above-mentioned embodiment in this embodiment will not be repeated one by one. This embodiment provides an embodiment of a double-sensor-based label detection method, including:

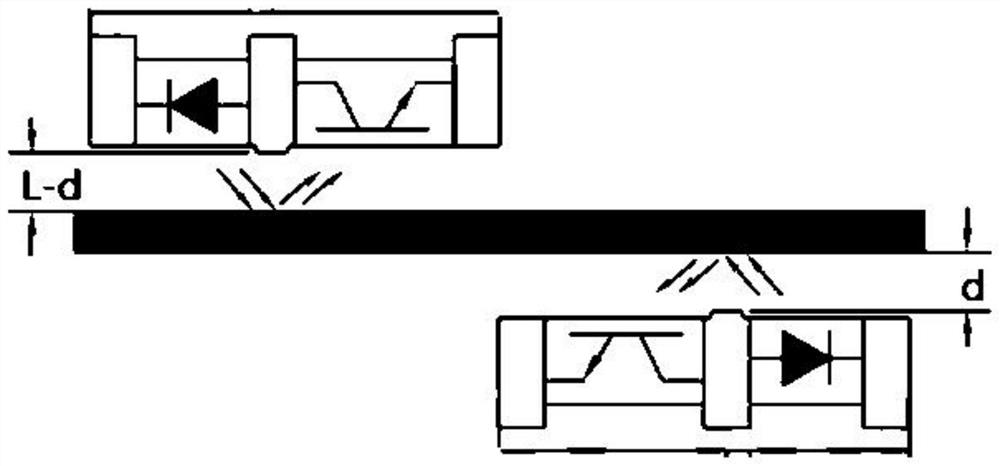

[0063] preferred, such as image 3 As shown, in step S100, the label is detected by the first sensor and the second sensor, and the first current intensity and the second current intensity are output, including:

[0064] Set the position of the first sensor and the second sensor.

[0065] The front side of the label is detected by the first sensor, and the first current intensity is output.

[0066] The reverse side of the label is detected by the second sensor, and the second current intensity is output.

[0067] Exemplary, the general structure is as follows image 3 As shown, the longitudinal distance of the sensor is represented by L, the distance between the paper and the front sensor is represented by...

Embodiment 3

[0077] Based on the above-mentioned embodiment, the parts that are the same as those in the above-mentioned embodiment in this embodiment will not be described one by one, such as image 3 , 5 As shown, this embodiment provides a label detection device based on dual sensors, including:

[0078] The first sensor 1 is separated from the front of the label by a first preset distance, and is used for detecting the front of the label, and outputs a first current intensity of the front of the label.

[0079] The second sensor 2 is separated from the reverse side of the label by a second preset distance, and is separated from the first sensor by a third preset distance, and is used to detect the reverse side of the label and output the reverse side of the label. second current intensity.

[0080] The calculation module 3 is connected with the first sensor and the second sensor, and is used for receiving the first current intensity and the second current intensity, and outputting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com