Melting device for glass fiber production

A melting device and glass fiber technology, applied in glass furnace equipment, glass manufacturing equipment, feeding of melting furnaces, etc., can solve problems such as damage to the respiratory system of workers, pollution of the natural environment, and low efficiency of defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

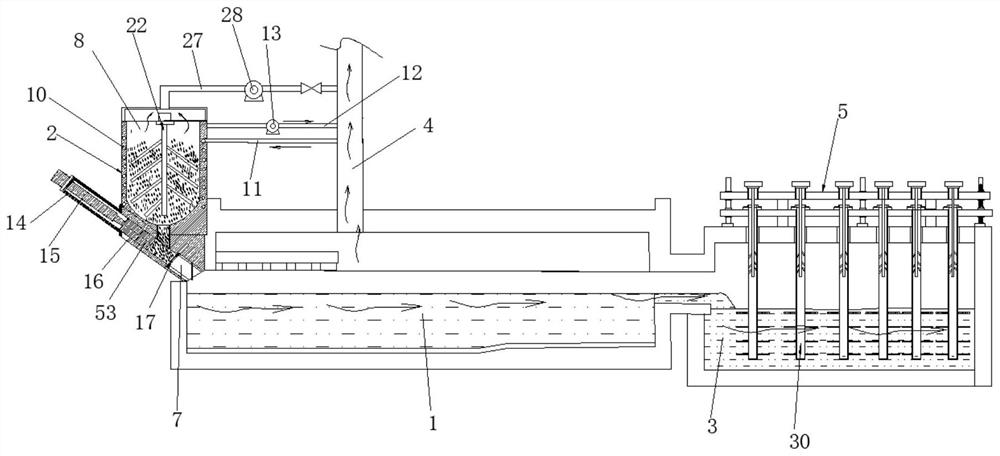

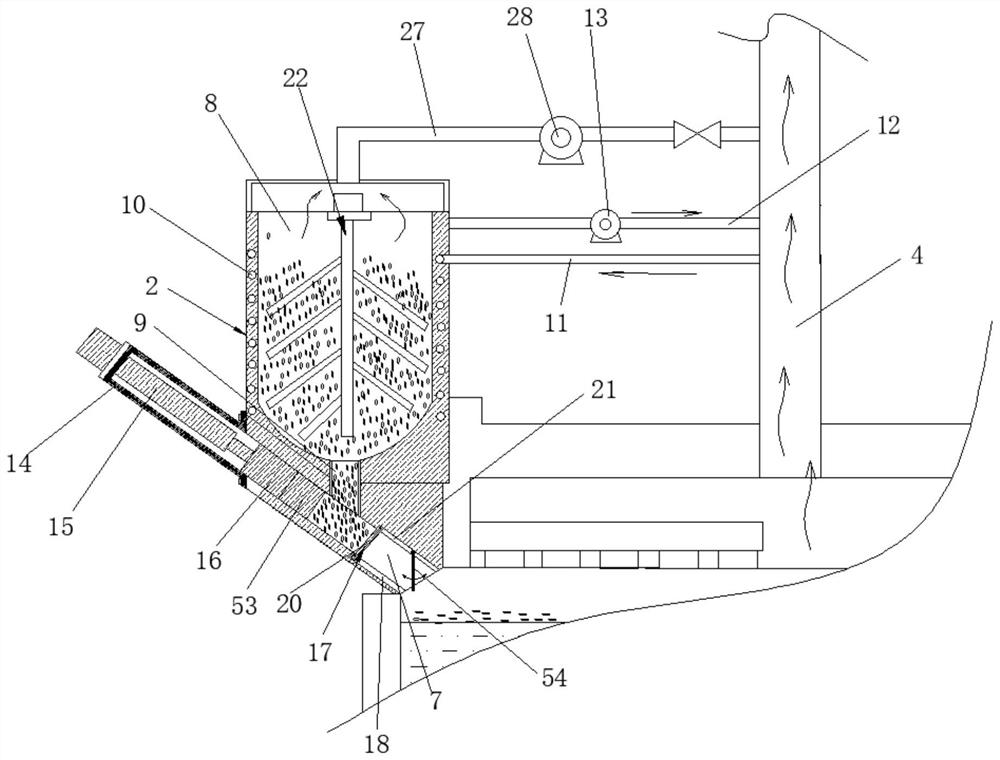

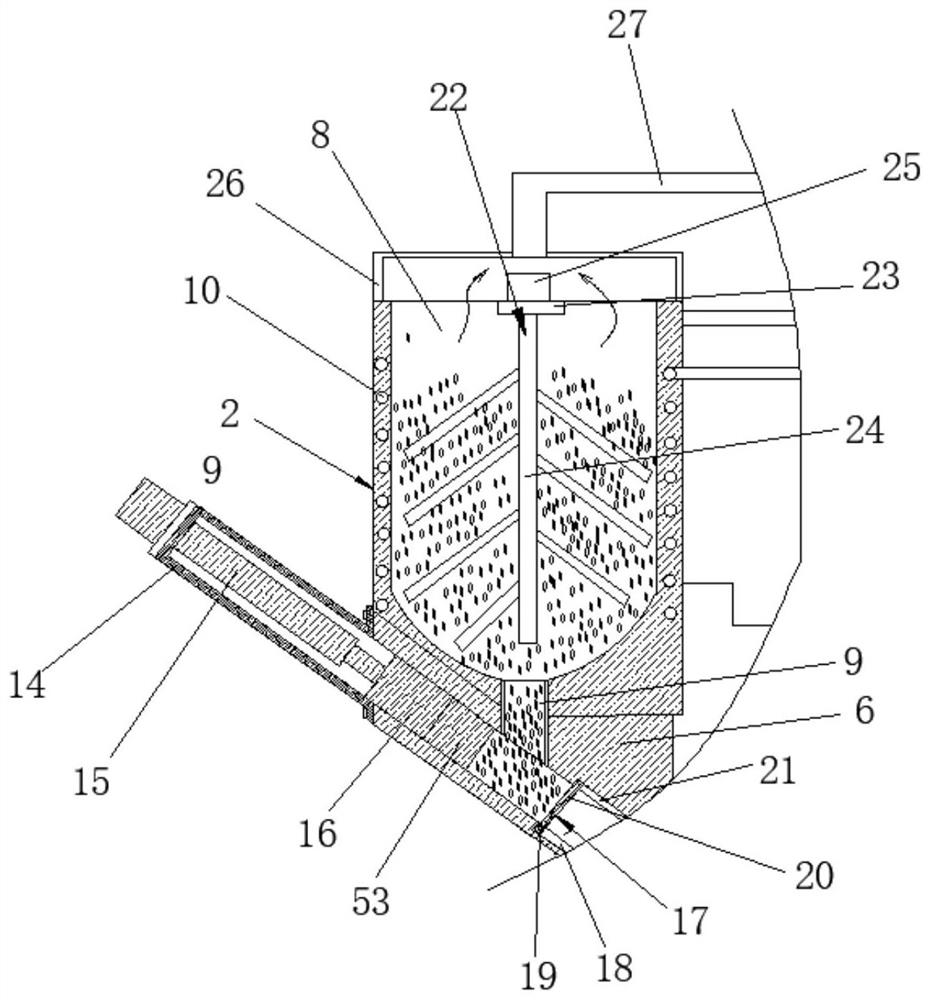

[0034] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, a melting device for glass fiber production in the present invention includes a channel-type melting pool 1, and is characterized in that the upstream end of the melting pool 1 is a melting zone, and the port at the upstream end is provided with a closed feeding mechanism 2. The downstream end of the melting pool 1 is provided with a melting zone, the final end of the melting pool 1 is provided with a clarification tank 3, and the top of the melting pool 1 is provided with a smoke exhaust pipe 4; A vibration defoaming mechanism 5 is provided; the closed feeding mechanism 2 includes a sealing block 6 arranged at the port of the upstream end, and the sealing block 6 is provided with a feeding chamber that is inclined downward and communicates with the melting pool 1 7. The side wall of the melting pool 1 is provided with a storage funnel 8, and the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com