A kind of heat preservation rigid melamine foam with low water absorption rate and preparation method thereof

A technology with low water absorption rate and water absorption rate, applied in the field of polymer materials, can solve the problems of inability to effectively hinder the penetration of water, low closed cell rate of melamine foam, and increased thermal conductivity, so as to reduce the water absorption rate and thermal conductivity of foam, and improve the The proportion of hydrophobic groups, the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

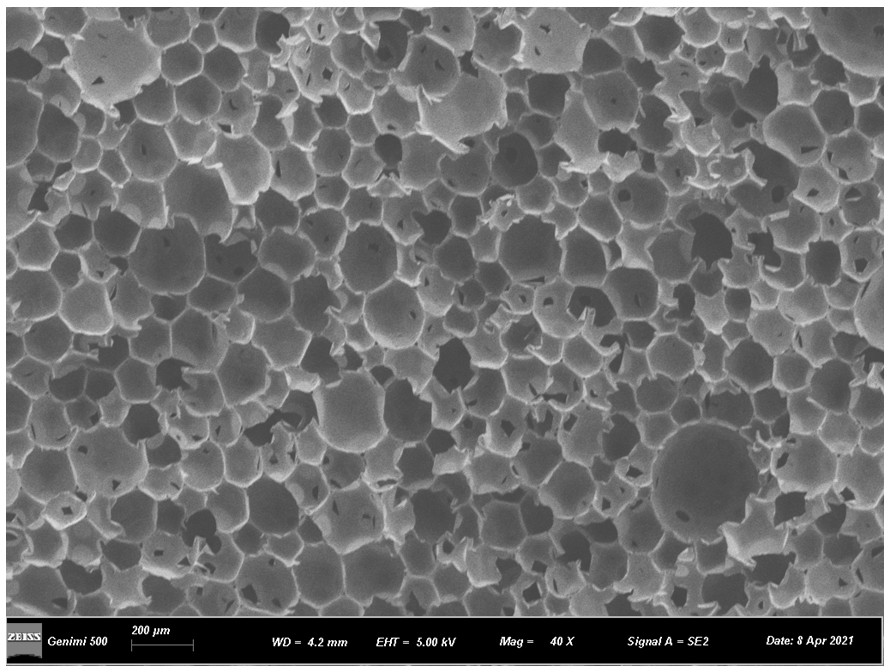

Image

Examples

Embodiment 1

[0022] The preparation operation steps of a kind of low water absorption rate thermal insulation rigid melamine foam are as follows:

[0023] (1) 176.7g of distilled water, 112.7g of paraformaldehyde, and 150g of melamine were successively added to the three-necked flask, and mixed and stirred at 85°C for 10 minutes to obtain a clear solution;

[0024] (2) 18g n-butanol and 1.2g hexamethylenetetramine were added to the clear solution, and the reaction was continued for 2.40h. After the reaction was completed, it was rapidly cooled to 30°C using a cold water bath to obtain a modified melamine resin prepolymerization solution;

[0025] (3) When the viscosity of the melamine resin prepolymer solution to be modified reaches 30Pa·s, add 2g nano-silica (100nm), 4g dimethyl silicone oil, 10g n-pentane to 200g modified melamine resin prepolymer solution alkane and 1.5g dodecylbenzenesulfonic acid, stir at a high speed of 1300r / min for 2min, then add 1.4g hydrochloric acid and stir at ...

Embodiment 2

[0028] The preparation operation steps of a kind of low water absorption rate thermal insulation rigid melamine foam are as follows:

[0029] (1) 176.7g of distilled water, 112.7g of paraformaldehyde, and 150g of melamine were successively added to the three-necked flask, and mixed and stirred at 85°C for 10 minutes to obtain a clear solution;

[0030] (2) 9g of n-butanol and 1.1g of hexamethylenetetramine were added to the clear solution, and the reaction was continued for 2.30h. After the reaction was completed, it was rapidly cooled to 30°C using a cold water bath to obtain a modified melamine resin prepolymerization solution;

[0031] (3) When the viscosity of the melamine resin prepolymer solution to be modified reaches 40Pa·s, add 4g nano-silica (100nm), 4.2g dimethyl silicone oil, 11g positive Pentane and 1g of dodecylbenzenesulfonic acid were stirred at a high speed of 1300r / min for 2.5min, and then 1.3g of hydrochloric acid was added and stirred at a high speed for 35...

Embodiment 3

[0034] The preparation operation steps of a low water absorption rate thermal insulation rigid melamine foam are as follows;

[0035] (1) 176.7g of distilled water, 112.7g of paraformaldehyde, and 150g of melamine were sequentially added to the three-necked flask, and mixed and stirred at 80°C for 10 minutes to obtain a clear solution;

[0036] (2) Add 18g n-butanol and 1.3g hexamethylenetetramine to the clear solution, and continue the reaction for 2.50h. After the reaction, use a cold water bath to rapidly cool to 25°C to obtain a modified melamine resin prepolymer solution ;

[0037] (3) When the viscosity of the melamine resin prepolymer solution to be modified reaches 35Pa s, add 2g micron silica (5um), 4g dimethyl silicone oil, 10g n-pentane and 1.4g tenon to 200g resin prepolymer solution. Dialkylbenzenesulfonic acid, stirred at a high speed of 1300 r / min for 2 minutes, then added 1.4 g of oxalic acid and stirred at a high speed for 25 s; foamed in an oven for 40 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com