Lithographic printing plate precursor, method for manufacturing lithographic printing plate, and lithographic printing method

A technology of lithographic printing plate and original plate, applied in lithographic printing equipment, printing, printing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

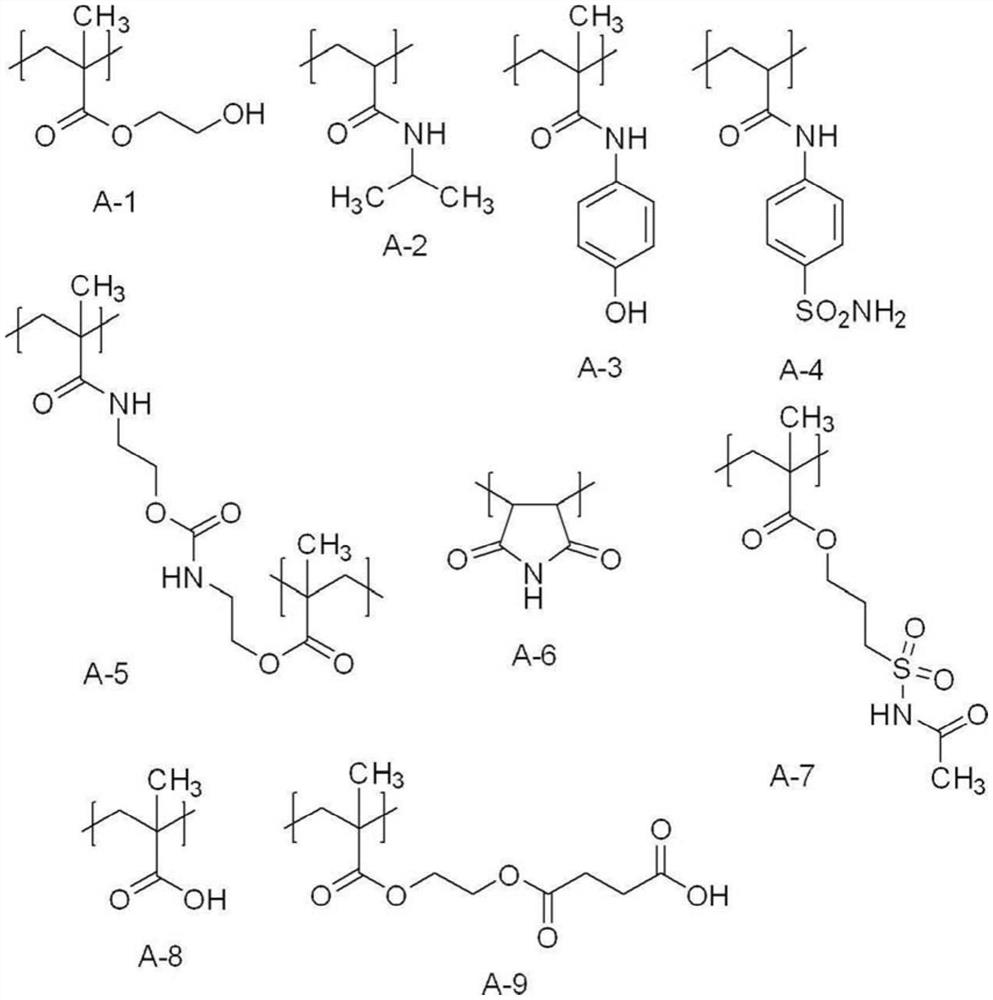

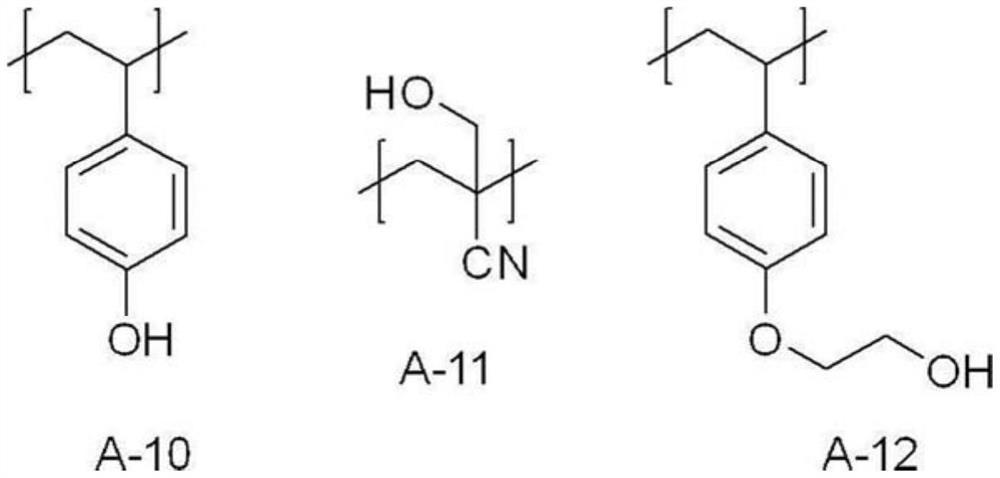

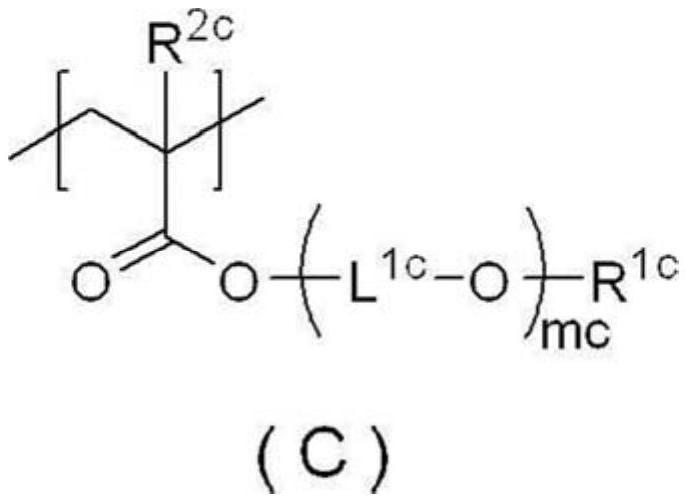

Method used

Image

Examples

Embodiment 1~ Embodiment 23 and comparative example 1~ comparative example 4

[0456]

[0457] On the support described in Table 3 or Table 4, the dry coating amount is 20 mg / m 2 An undercoat layer coating solution (1) having the following composition was applied in the same manner as in the following manner to form an undercoat layer.

[0458] -Undercoat coating liquid (1)-

[0459] ・Polymer (P-1) [structure below]: 0.18 parts

[0460] · Hydroxyethyliminodiacetic acid: 0.10 parts

[0461] ·Water: 61.4 parts

[0462] [chemical formula 16]

[0463]

[0464]

[0465] The lithographic printing plate precursors of Examples 1 to 13 and Comparative Examples 1 to 4 were prepared by the following methods.

[0466] Each image-recording layer coating solution (6% solid content) having the composition described in Table 3 or Table 4 was bar-coated on the undercoat layer, and dried at 120° C. for 40 seconds to form a dry coating Amount 1.0g / m 2 image recording layer.

[0467] If necessary, bar-coat the protective layer coating solution of the above com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com