Method of manufacturing support for planographic printing plate

Technology of a lithographic printing plate, manufacturing method, applied in the direction of preparation of printing surface, printing, printing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0379] 1. Manufacture of aluminum plate

[0380] Prepare a melt with an aluminum alloy containing the components (mass %) shown in Table 1, and the balance is composed of Al and unavoidable impurities. After the melt is treated and filtered, the thickness is 500mm and the width is produced by DC casting. 1200mm ingot. After shaving the surface with an average thickness of 10 mm by a face cutter, it was soaked at 550° C. for about 5 hours, cooled to a temperature of 400° C., and rolled into a rolled plate with a thickness of 2.7 mm by a hot rolling machine. Further, after heat-treating at 500° C. with a continuous annealing machine, it was cold-rolled and finished to a thickness of 0.3 mm and a width of 1060 mm to obtain an aluminum plate 1 .

[0381] Table 1

[0382] Aluminum plate Si Fe Cu mn Mg Cr Zn Ti 1 0.080 0.300 0.001 0.001 0.000 0.001 0.003 0.021

[0383] 2. Production of supports for lithographic printin...

Embodiment 1~24 and comparative example 1~9

[0385] The aluminum plate obtained above was subjected to the surface treatment shown below to obtain each support body for lithographic printing plates shown in Table 2.

[0386] Table 2

[0387]

[0388]

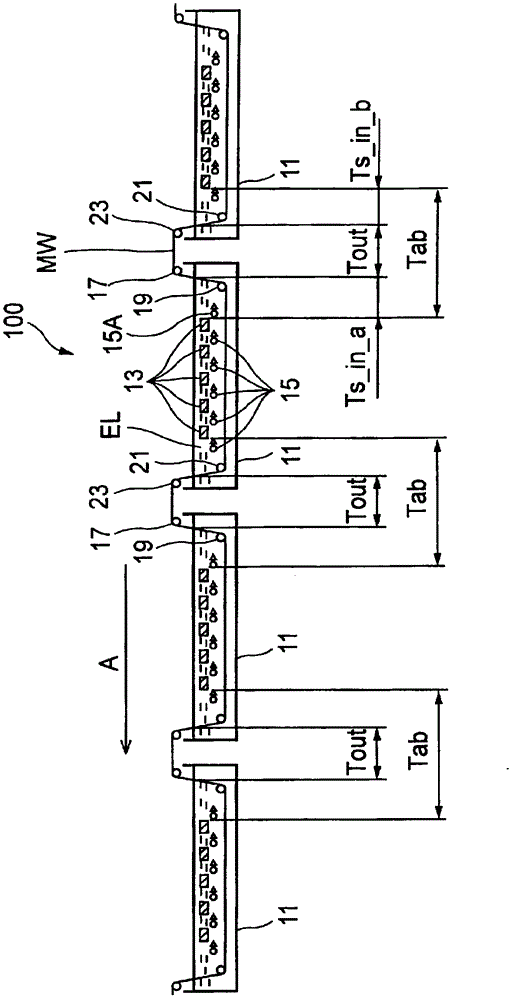

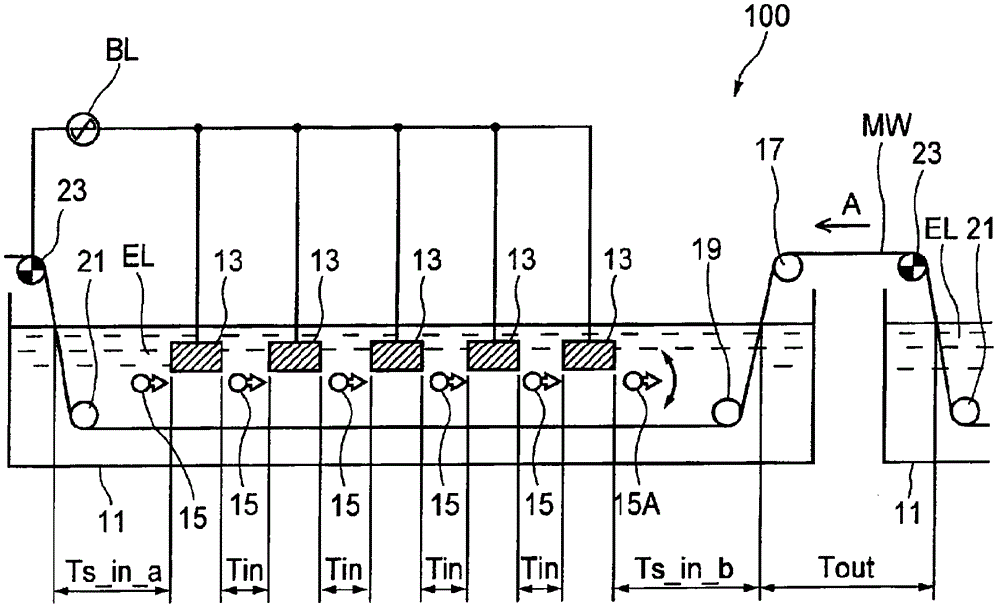

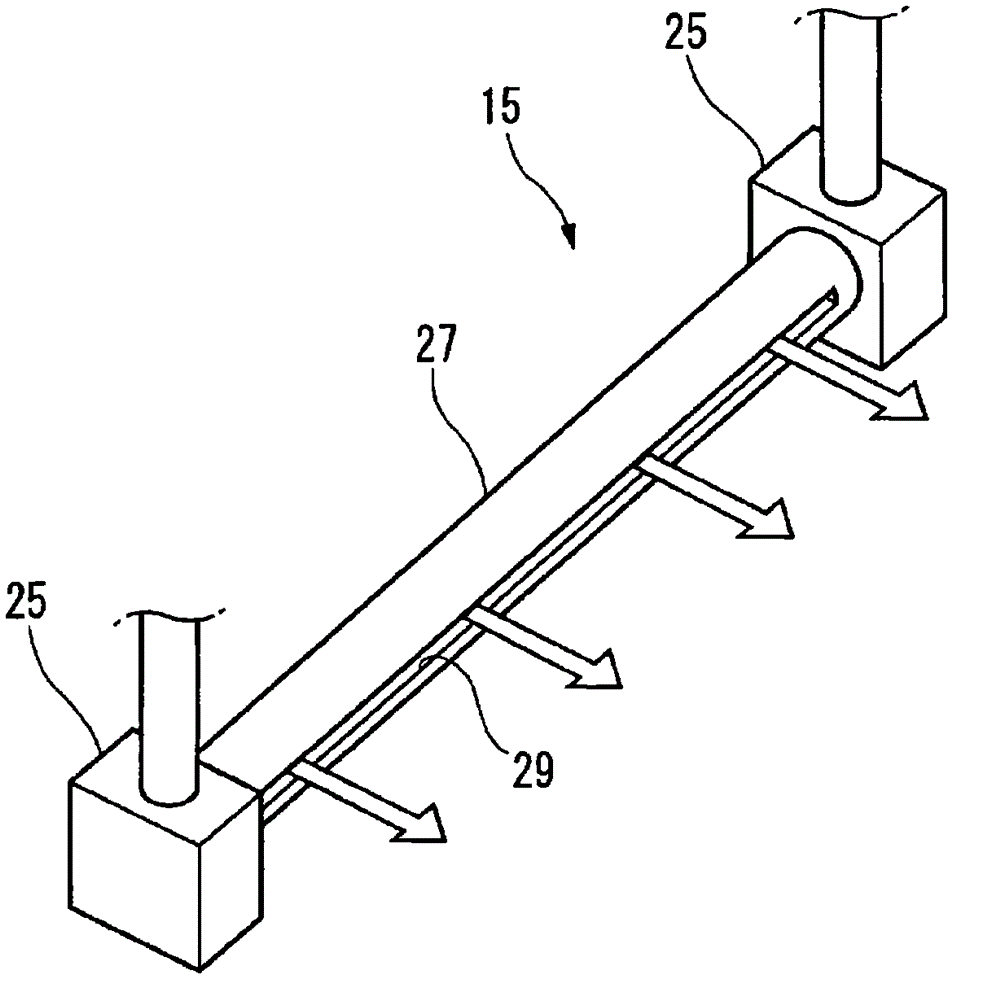

[0389] In the surface treatment, the following various treatments (a) to (g) are continuously performed.

[0390] (a) Etching treatment in aqueous alkali solution (first etching treatment)

[0391] An aqueous solution having a caustic soda concentration of 370 g / L, an aluminum ion concentration of 1 g / L, and a temperature of 60° C. was sprayed on the aluminum plate from a spray pipe to perform etching treatment. The amount of etching on the surface of the aluminum plate to be subjected to electrochemical roughening treatment is 3g / m 2 .

[0392] Then, the solution was passed through the pinch rolls, and then washed with water for 5 seconds using a spray pipe having a spray tip that spreads the spray water in a fan shape, and then the liquid was squeezed with the p...

Embodiment 1~24、 comparative example 1~9

[0419] A primer liquid A having the following composition was coated on a lithographic printing plate support, and dried at 80° C. for 15 seconds to form a coating film (intermediate layer) of the components. Coverage of the dried coating film is 15mg / m 2 .

[0420]

[0421] ・The following polymer compound 0.3g

[0422] ·Methanol 100g

[0423] ·Water 1g

[0424]

[0425]Next, in terms of ingredients, it is 0.85g / m after drying 2 Coating solution B1 for an image recording layer having the following composition was applied with a wire bar coater, and dried at 140° C. for 50 seconds.

[0426] Then, according to 0.25g / m after drying 2 Coating solution B2 for the image recording layer with the following composition was applied with a wire bar coater, and dried at 140°C for 1 minute to form a multilayer thermal positive image recording layer to obtain a lithographic printing plate precursor .

[0427]

[0428] N-(4-aminosulfonylphenyl)methacrylamide / acrylonitrile / methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com