Securing of stator segments

A technology of stator segments and stators, applied in threaded fasteners, thin plate connections, electromechanical devices, etc., can solve problems such as complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

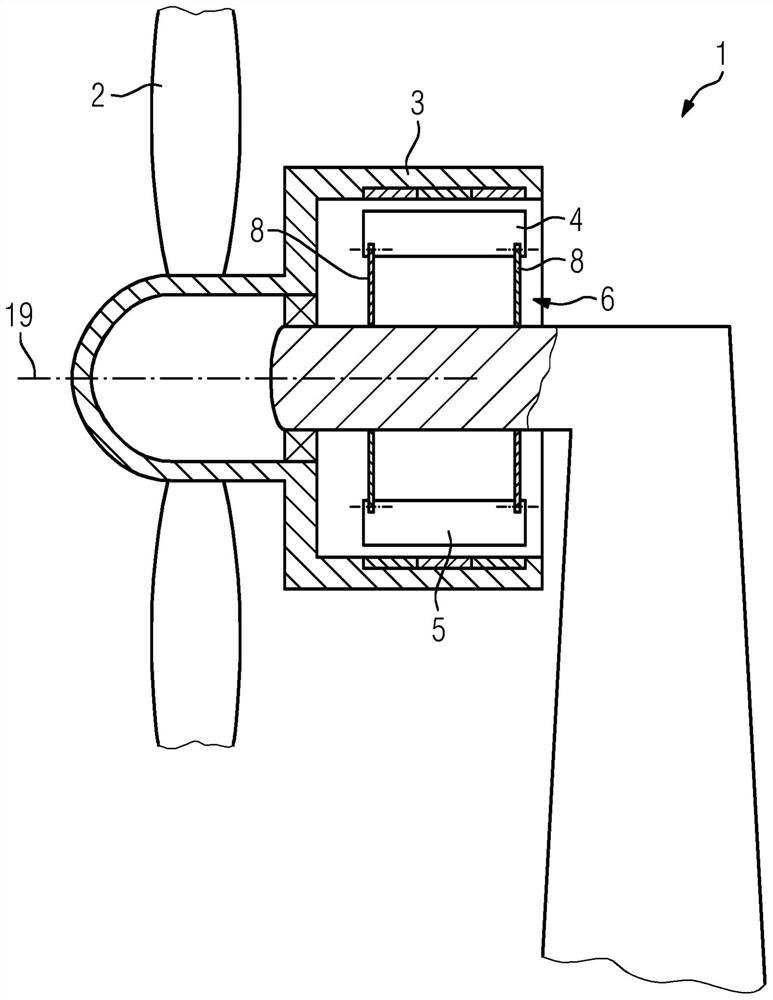

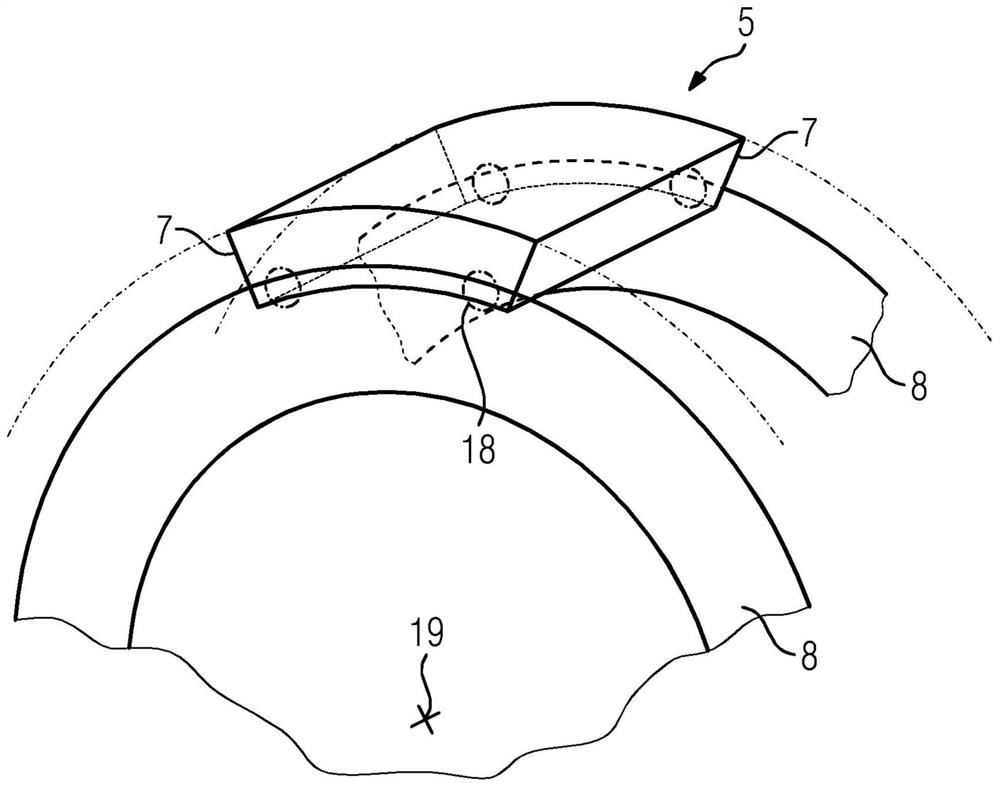

[0037] figure 1 A schematic diagram of a wind power plant 1 with a direct-drive wind generator with an external rotor is shown. The rotor 3 here has permanent magnets, which are not shown in more detail and which interact electromagnetically with the coil system of the stator 4 (the coil system is not shown in more detail), and are rotated around the axis 19 by the turbine 2 of the wind power plant 1 rotation, thus providing electrical energy. When viewed in the circumferential direction, the stator 4 is subdivided into stator segments 5 which are supported in each case on a stator support 6 which has two flanges 8 extending in parallel.

[0038] Such as figure 2 In this illustration, the stator segment 5 is fastened to the stator support 6 by means of suitable fastening means by means of four fastening points 18 , which will be described in more detail.

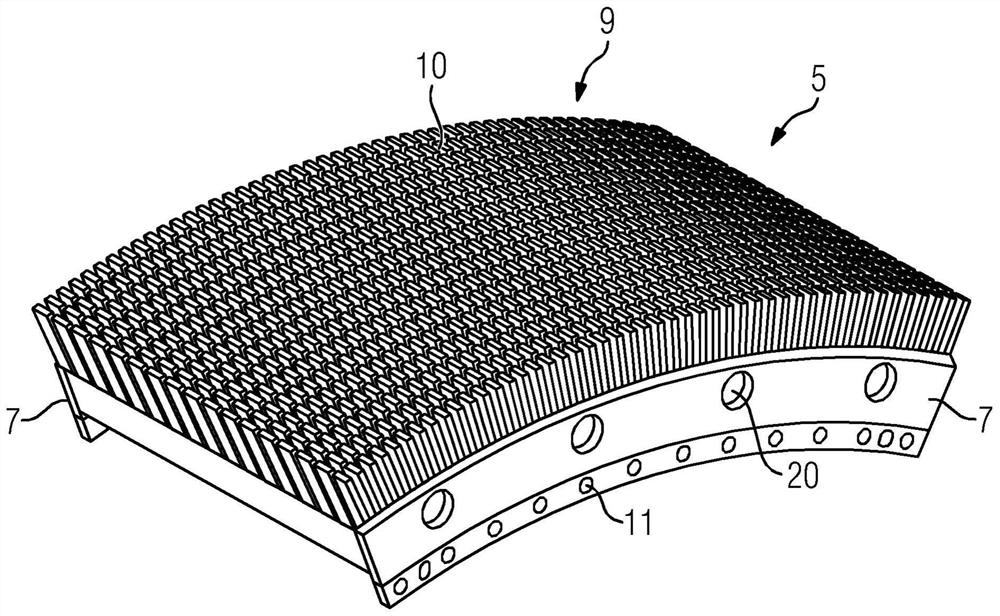

[0039] The stator segment 5 has a laminated core 9 with axially parallel grooves 10 in which a coil system (not descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com