Large-scale livestock breeding equipment based on RFID and camera

A camera and poultry technology, applied in the field of poultry breeding, can solve the problems of food pollution, poultry trampling on food, food waste and cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

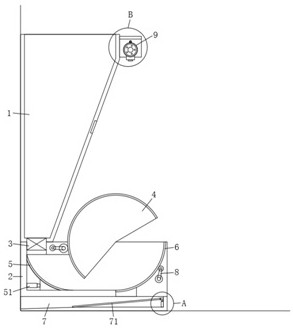

[0039] In this embodiment, the breeding equipment includes the following structure:

[0040] feeding hopper 1;

[0041] At least one base 2 fixed on the bottom of the feeding hopper 1, the base 1 is provided with a material guide cavity, and a quantitative solenoid valve 3 is connected between each material guide cavity and the feed hopper 1;

[0042] The trough 4 is rotatably installed on the top of the base 2, and the axial cross-sectional shape of the trough 4 is an arc greater than 1 / 2 and less than 3 / 5;

[0043] The first guide plate 5 and the second guide plate 6 arranged inside the material guide chamber, the first guide plate 5 and the second guide plate 6 can be combined to form an arc-shaped section greater than 2 / 5 and less than 1 / 2, and wrapped around the trough 4 On the outer wall; the first guide plate 5 is moved and installed, and is used to guide the breeding food fed by the quantitative solenoid valve 3 to between the first guide plate 5 and the second guide ...

Embodiment 2

[0064] In this embodiment, the breeding equipment includes the following structure:

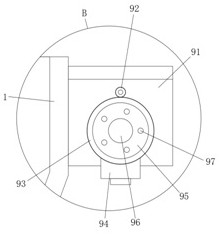

[0065] Feeding hopper 1 with the same structure as the first embodiment above; base 2; quantitative solenoid valve 3; food trough 4; first guide plate 5; second guide plate 6; RFID tag; tag reader; camera assembly 9.

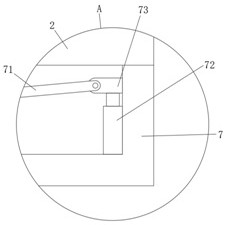

[0066] Compared with the structure of the first embodiment above, the sewage tank 7 is added;

[0067] The sewage discharge tank 7 is fixed on the bottom of the base 2, and a sewage discharge port is connected between the sewage discharge tank 7 and the material guide chamber.

[0068] The second guide plate 6 is set to be rotated and installed, and the second guide plate 6 rotates coaxially with the food trough 4; a side of the second guide plate 6 is provided with a rotation drive 8, and the rotation drive 8 includes a drive motor and a drive gear, The driving gear is driven to rotate by the driving motor, and the driving gear meshes with the outer wall of the second guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com