Power adjusting circuit, power adjusting method and electric chafing dish

A power adjustment and circuit technology, which is applied to cooking utensils, timing control ignition mechanisms, heating devices, etc., can solve the problems of burning food and adjusting heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

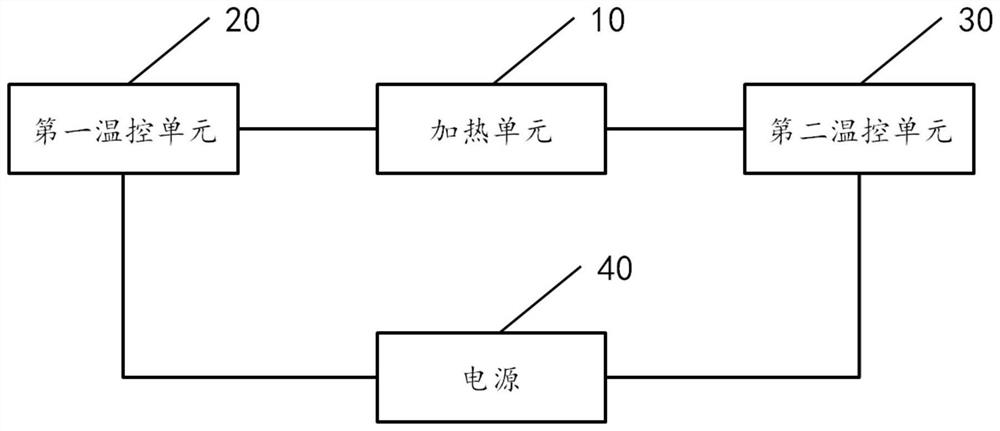

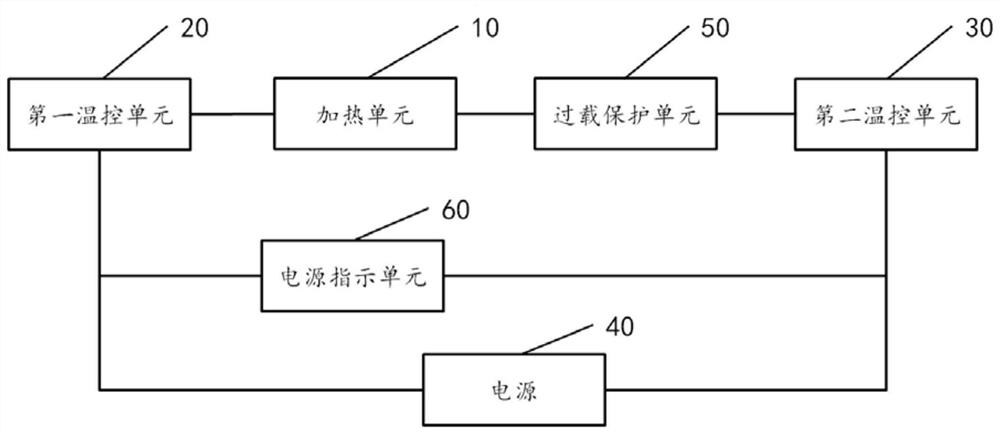

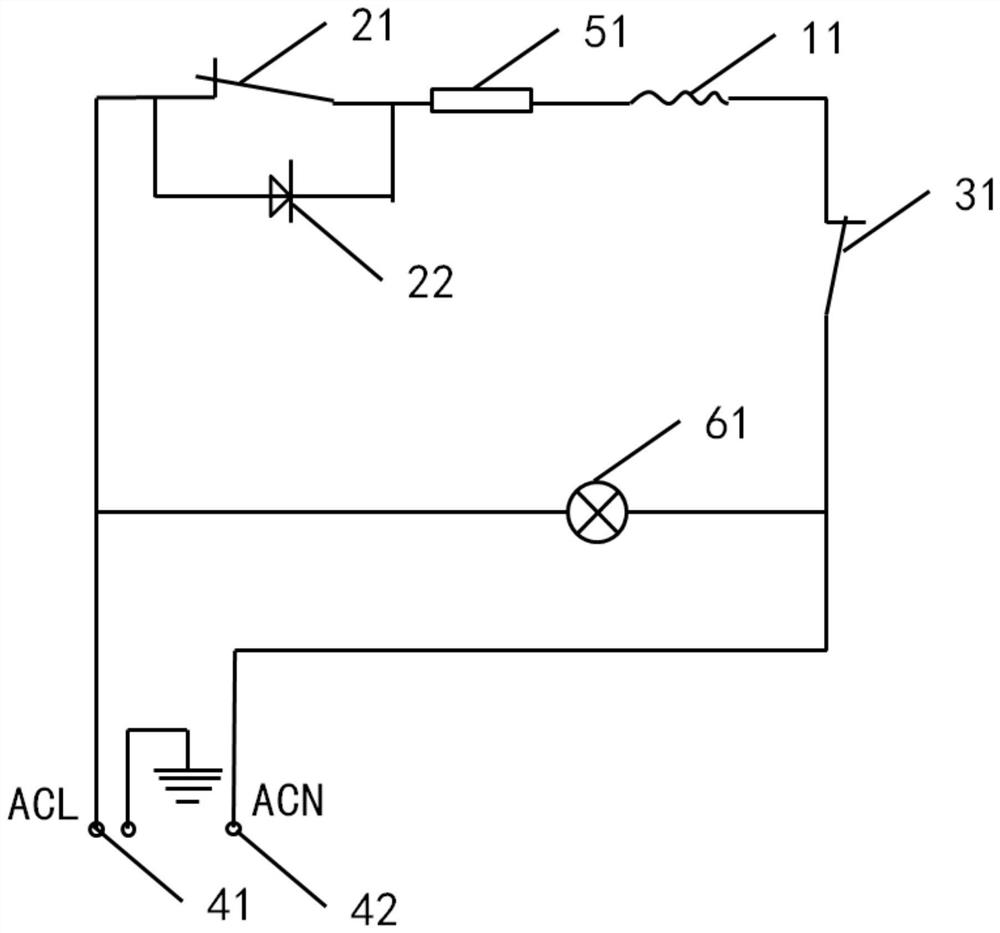

[0056] see figure 1 and image 3 , figure 1 It is a block diagram of a power adjustment circuit disclosed in an embodiment of the present invention, image 3 It is a power adjustment circuit diagram disclosed by the embodiment of the present invention. like figure 1 and image 3 As shown, the power regulation circuit may include:

[0057] The heating unit 10, the first temperature control unit 20 and the second temperature control unit 30, one end of the heating unit 10 is electrically connected to one end of the first temperature control unit 20, and the other end of the heating unit 10 is electrically connected to one end of the second temperature control unit 30 , the other end of the first temperature control unit 20 is used to electrically connect the first pole 41 of the power supply 40, and the other end of the second temperature control unit 30 is used to electrically connect the second pole 42 of the power supply 40;

[0058] Wherein, the heating unit 10 include...

Embodiment 2

[0084] see Figure 4 , Figure 4 It is a flow chart of a power adjustment method disclosed by an embodiment of the present invention. like Figure 4 As shown, the power adjustment method may include the following operations:

[0085] 101. Adjust the adjustable temperature controller 31 so that the heating element 11 is heated with the first power.

[0086] In the embodiment of the present invention, the adjustable temperature controller 31 has at least one gear. For example, the gears are divided into three gears: high gear, middle gear and low gear. The adjustable temperature controller 31 can be in the high gear , switch between the middle gear and the low gear, it should be noted that, when the adjustable temperature controller 31 is respectively adjusted to the high gear, the middle gear and the low gear, the heating element 11 is heated with the first power.

[0087] In the embodiment of the present invention, the first power is the maximum full power. When the heatin...

Embodiment 3

[0095] see Figure 5 , Figure 5 It is a flow chart of a power adjustment method disclosed by an embodiment of the present invention. like Figure 5 As shown, the power adjustment method may include the following operations:

[0096] 201. Adjust the adjustable temperature controller 31, so that the heating element 11 is heated with the first power.

[0097] 202. Determine whether the temperature of the heating element 11 is greater than or equal to the first trigger temperature. When the judgment result of step 202 is yes, trigger the execution of step 203; when the judgment result of step 202 is no, trigger the execution of step 204.

[0098] 203. Control the kick thermostat 21 to switch from the on state to the off state, so that the heating power of the heating element 11 is switched from the first power to the second power, wherein the first power is greater than the second power.

[0099] 204. Control the kick thermostat to keep in a conducting state, so that the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com