Uniform painting equipment for wooden rod material

A uniform, rod-like technology, used in spray booths, spray devices, liquid spray devices, etc., to solve problems such as low spray uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

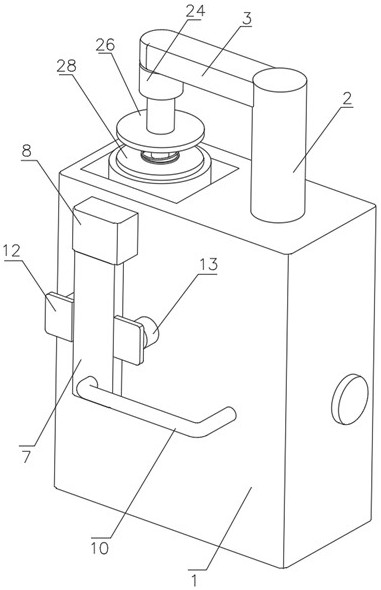

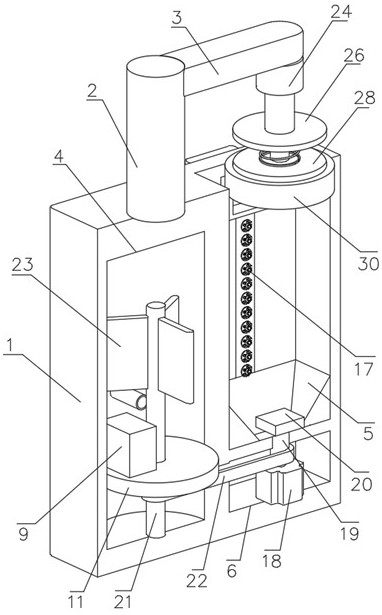

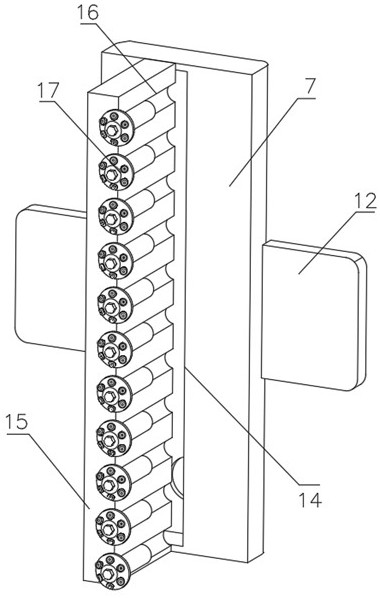

[0023] refer to figure 1 , figure 2 and Figure 4 , a kind of equipment for uniform painting of wooden rods, comprising a processing box 1, the upper end of the processing box 1 is rotatably connected with a column 2, the side wall of the column 2 is fixed with a hanging plate 3, and the bottom of the hanging plate 3 is provided with a pressing mechanism, The inside of the processing box 1 is provided with a paint chamber 4, the inner wall of the paint chamber 4 is fixed with a support plate 11, the upper end of the support plate 11 is fixed with a delivery pump 9, and the inner bottom of the processing box 1 is fixed with a positioning block 5, and the positioning block 5 The center is sunken, and the inner wall is an inclined plane. The rod material placed on it will automatically slide towards the center position, thereby realizing the automatic positioning of the rod material. The lower part of the processing box 1 is provided with a drive chamber 6, and a rotary drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com