A stable injection mold for automobile bumper

A technology for automobile bumpers and injection molds, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, non-rotational vibration suppression, etc. It can solve the problems of difficult air discharge from materials, standard deviation of bumpers, and single movement mode. To achieve the effect of increasing the service life, improving the stability of the die, and increasing the form of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

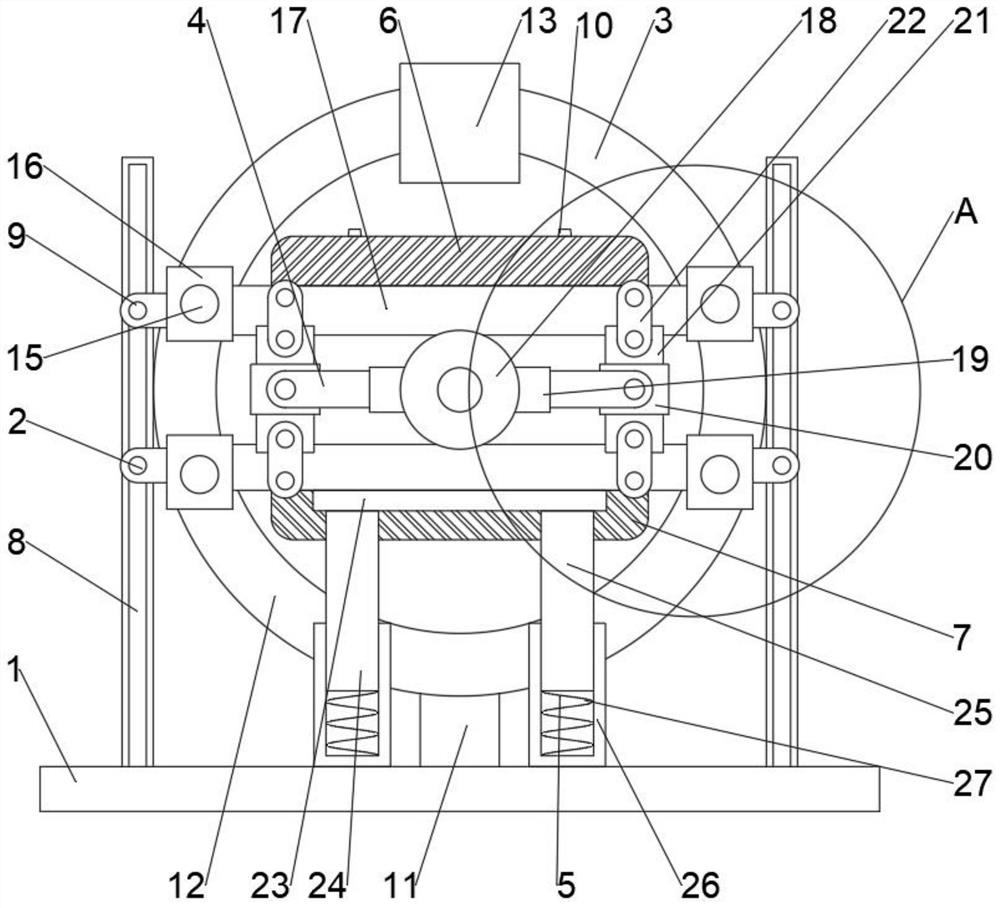

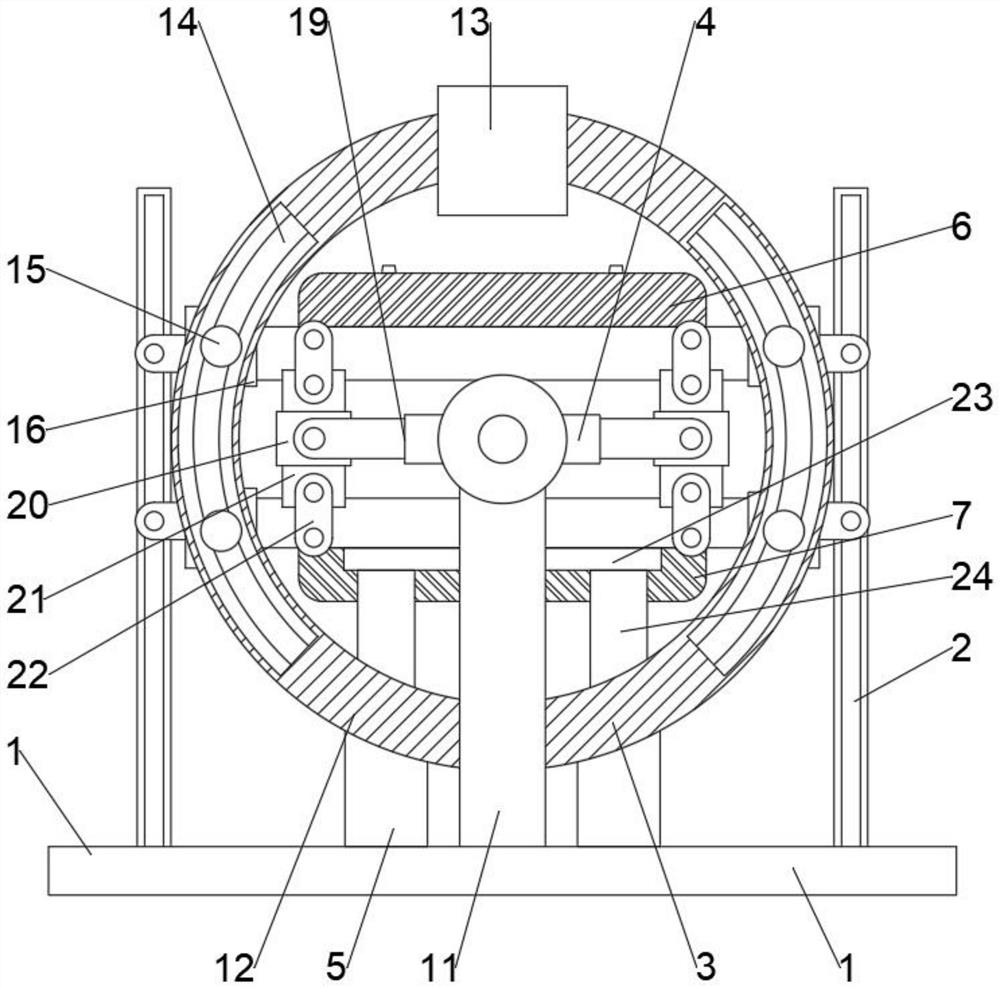

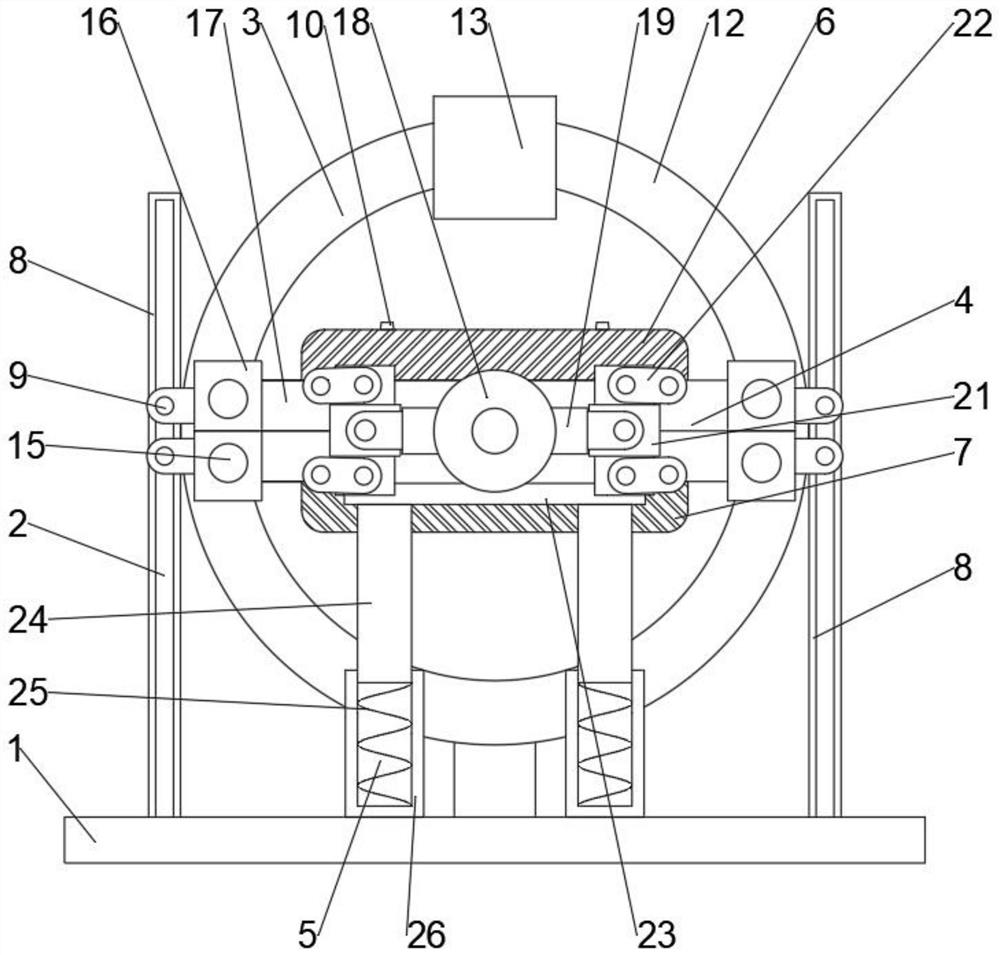

[0025] like Figure 1-5 As shown, a stable injection mold for an automobile bumper proposed by the present invention includes a frame 1, a lifting component 2, a rotating component 3, a die component 4 and a buffer component 5; the lifting component 2, the rotating component 3 and the buffer component 5; 5 is arranged on the frame 1; the die assembly 4 is arranged on the rotating assembly 3; the buffer assembly 5 is located below the die assembly 4; the upper die 6 and the lower die 7 are provided with a ventilation valve 10; Rotating base 11, turntable 12, driving member 13, rotating track 14, sliding base 15 and moving base 16; the rotating base 11 is arranged on the rack 1; the turntable 12 is arranged on the rotating base 11; The sliding seat 15 driven by the driving member 13 is slidably arranged on the rotating track 14; the moving seat 16 is arranged on the sliding seat 15 and is slidably connected with the turntable 12; The telescopic rod 19, the sleeve plate 20, the ...

Embodiment 2

[0029] like Figure 1-5 As shown, the present embodiment proposes a stable injection mold for an automobile bumper. Compared with the first embodiment, the lift assembly 2 includes a lift track 8 and a lift seat 9; the lift track 8 is arranged on the frame 1; the lift seat 9 slides Set on the lift rail 8 .

Embodiment 3

[0031] like Figure 1-5 As shown, the present embodiment proposes a stable injection mold for an automobile bumper. Compared with the first embodiment, the buffer assembly 5 includes a buffer plate 23 and a buffer seat 24; the buffer seat 24 is arranged on the frame 1; the buffer plate 23 is arranged On the buffer seat 24 and below the die plate 17 .

[0032] By setting the buffer assembly 8, the buffer plate 23 and the buffer seat 24 are used to protect the upper die 6 or the lower die 7 from buffering and shock absorption, thereby improving the service life of the components in the present invention and increasing the use times of the upper die 6 and the lower die 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com