Stable injection mold for automobile bumper

A technology for automobile bumpers and injection molds, which is used in springs/shock absorbers, vibration suppression adjustment, non-rotational vibration suppression, etc., and can solve problems such as inconvenience for widespread promotion, standard deviation of bumpers, and difficulty in discharging air contained in materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

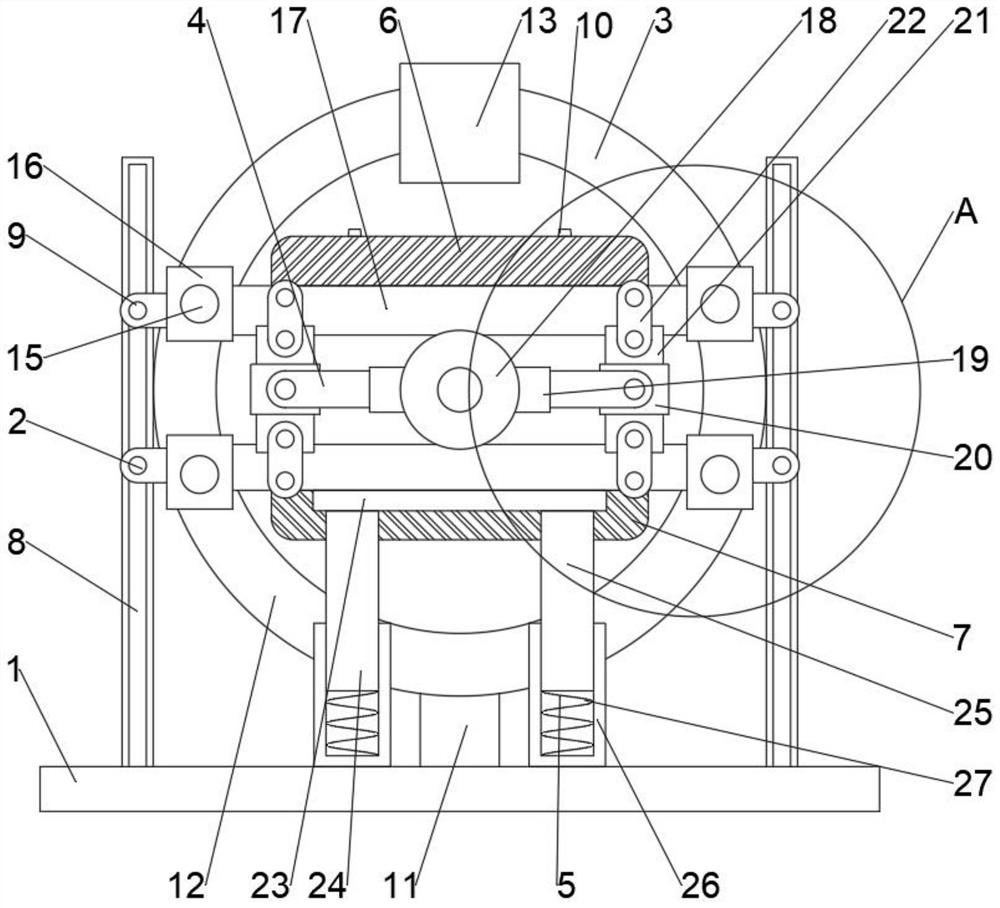

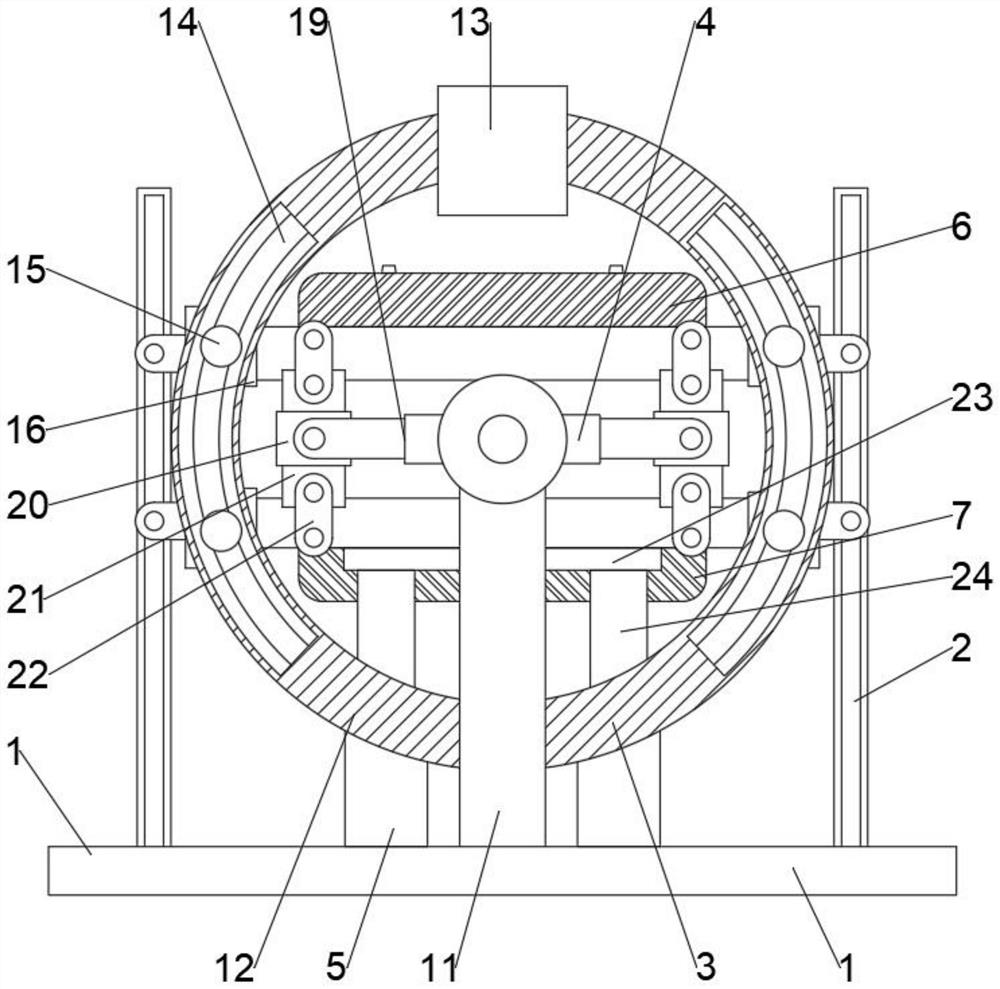

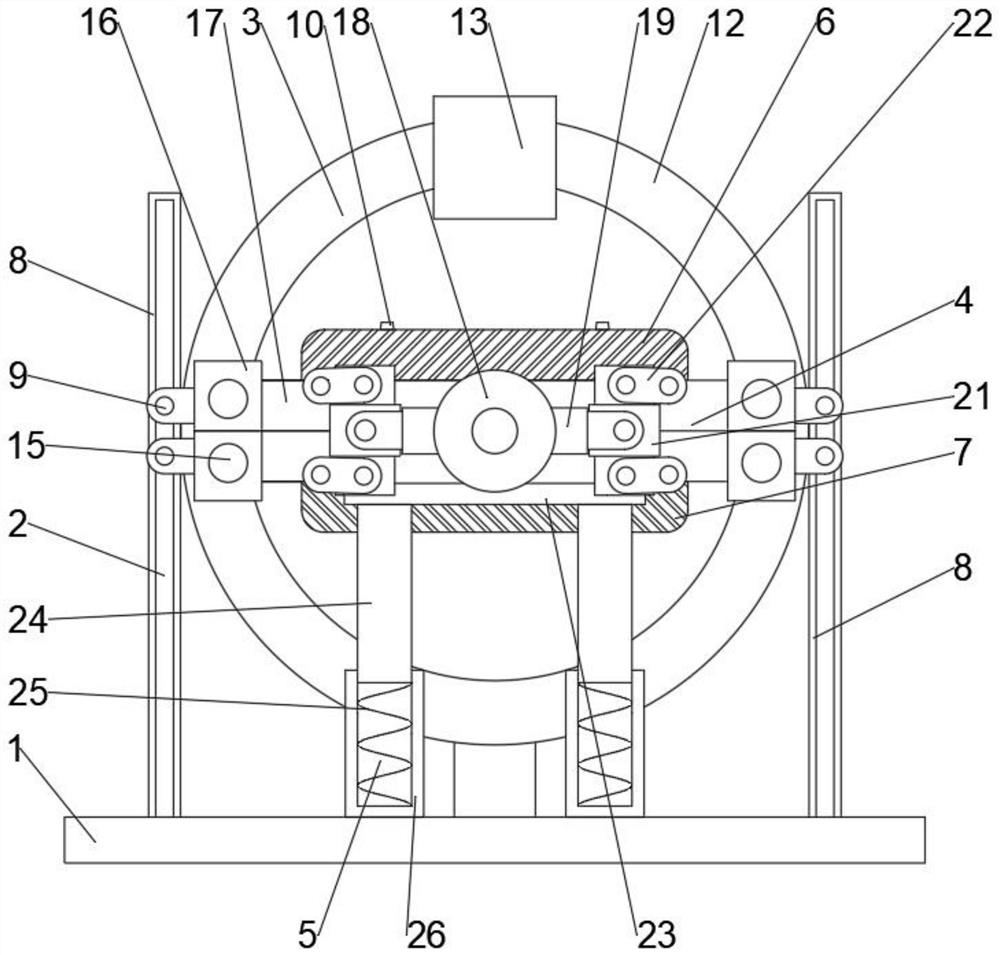

[0025] Such as Figure 1-5 As shown, a stable injection mold for automobile bumper proposed by the present invention includes frame 1, lifting assembly 2, rotating assembly 3, die assembly 4 and buffer assembly 5; lifting assembly 2, rotating assembly 3 and buffer assembly 5 is arranged on the frame 1; the compression mold assembly 4 is arranged on the rotary assembly 3; the buffer assembly 5 is located below the compression mold assembly 4; the upper mold 6 and the lower mold 7 are provided with a vent valve 10; the rotary assembly 3 includes Turning seat 11, rotating disk 12, driver 13, rotating track 14, sliding seat 15 and moving seat 16; Turning seat 11 is arranged on the frame 1; The sliding seat 15 driven by the driver 13 is slidably arranged on the rotating track 14; the moving seat 16 is arranged on the sliding seat 15, and is slidably connected with the turntable 12; Telescopic rod 19, cover plate 20, sliding plate 21 and rotating member 22; Die plate 17 is detachab...

Embodiment 2

[0029] Such as Figure 1-5 As shown, the present embodiment proposes a stable injection mold for automobile bumper. Compared with Embodiment 1, the lifting assembly 2 includes a lifting track 8 and a lifting seat 9; the lifting track 8 is arranged on the frame 1; the lifting seat 9 slides Set on the lifting track 8.

Embodiment 3

[0031] Such as Figure 1-5 As shown, the present embodiment proposes a stable injection mold for automobile bumper. Compared with Embodiment 1, the buffer assembly 5 includes a buffer plate 23 and a buffer seat 24; the buffer seat 24 is arranged on the frame 1; the buffer plate 23 is arranged On the buffer seat 24 and below the mold plate 17 .

[0032] By arranging the buffer assembly 8, the buffer plate 23 and the buffer seat 24 are used to buffer and protect the upper mold 6 or the lower mold 7, thereby improving the service life of the parts in the present invention and increasing the number of times of use of the upper mold 6 and the lower mold 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com