Leather and silica gel compound as well as preparation method and application thereof

A composite, silicone technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as easy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

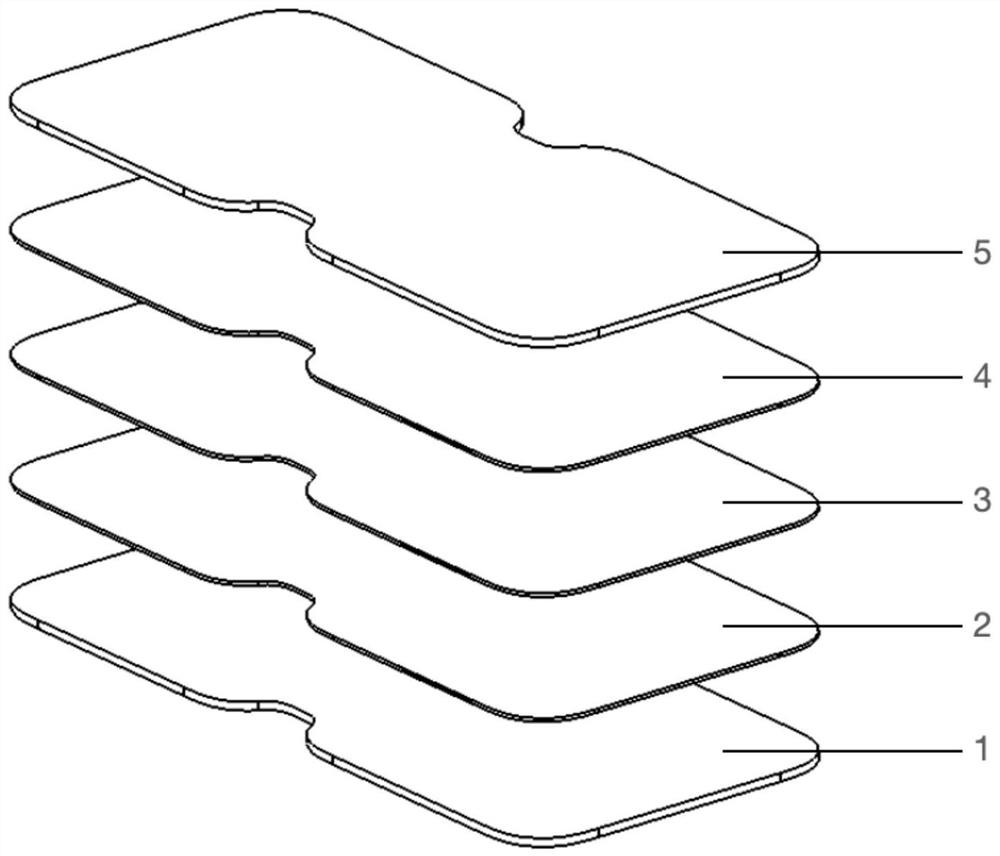

[0046] This embodiment provides a leather and silicone composite, such as figure 1 As shown, the leather and silica gel composite includes, from bottom to top, a silica gel layer 1, a precoat layer 2, a first heat-sensitive adhesive layer 3, a second heat-sensitive adhesive layer 4, and a leather layer 5 that are sequentially stacked;

[0047] The thickness of the silica gel layer is 0.74mm, and the silica gel is purchased from Pioneer Materials Technology Company, and the brand name is PMP-P-2300-B;

[0048] The thickness of the pre-coat layer is 1.5 μm, and the material is a mixture of acrylic ester resin and alcohol ether, purchased from Lord Company, and the brand name is Lord IMB 3050;

[0049] The thickness of the first heat-sensitive adhesive layer is 0.05 μm, and the material is polyurethane plastic, purchased from HB Fuller Company, the brand is HB Fuller EM9002N;

[0050] The thickness of the second heat-sensitive adhesive layer is 0.05 μm, and the material is polyu...

Embodiment 2

[0058] This embodiment provides a leather and silicone composite, which includes a silicone layer, a pre-coat layer, a first heat-sensitive adhesive layer, a second heat-sensitive adhesive layer, and a leather layer that are sequentially stacked from bottom to top ;

[0059] The thickness of the silica gel layer is 0.5 mm, and the silica gel is purchased from Pioneer Materials Technology Company, and the brand name is PMP-P-2300-B;

[0060] The thickness of the pre-coating layer is 1.8 μm, and the material is urethane resin, purchased from HB Fuller Company, and the brand name is HBFuller 3000F;

[0061] The thickness of the first heat-sensitive adhesive layer is 0.15 μm, and the material is polyurethane plastic, purchased from Bemis Company, and the brand name is Bemis 3415;

[0062] The thickness of the second heat-sensitive adhesive layer is 0.05 μm, and the material is polyurethane plastic, purchased from HB Fuller Company, and the brand name is HB Fuller EM9002N;

[006...

Embodiment 3

[0070] This embodiment provides a leather and silicone composite, which includes a silicone layer, a pre-coat layer, a first heat-sensitive adhesive layer, a second heat-sensitive adhesive layer, and a leather layer that are sequentially stacked from bottom to top ;

[0071] The thickness of the silica gel layer is 1 mm, and the silica gel is purchased from Pioneer Materials Technology Company, and the brand name is PMP-P-2300-B;

[0072] The thickness of the pre-coating layer is 1.5 μm, and the material is polyamide, which is purchased from Desa Company, and the brand name is 60151;

[0073] The thickness of the first heat-sensitive adhesive layer is 0.08 μm, and the material is polyurethane plastic, purchased from HB Fuller Company, the brand is HB Fuller EM9002N;

[0074] The thickness of the second heat-sensitive adhesive layer is 0.10 μm, and the material is polyimide plastic, purchased from Tesa Company, the brand name is Tesa 8710;

[0075] The leather layer has a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com