A kind of composite barium sulfate filler master batch for transparent plastic filling and preparation method

A technology for filling master batch and transparent plastic, which is applied in the field of compound barium sulfate filling master batch and preparation, can solve the problems of reducing use and processing costs, reducing the amount of plastic used, and needs to be improved, and achieves improved strength, good transparency, and improved alignment. sequential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

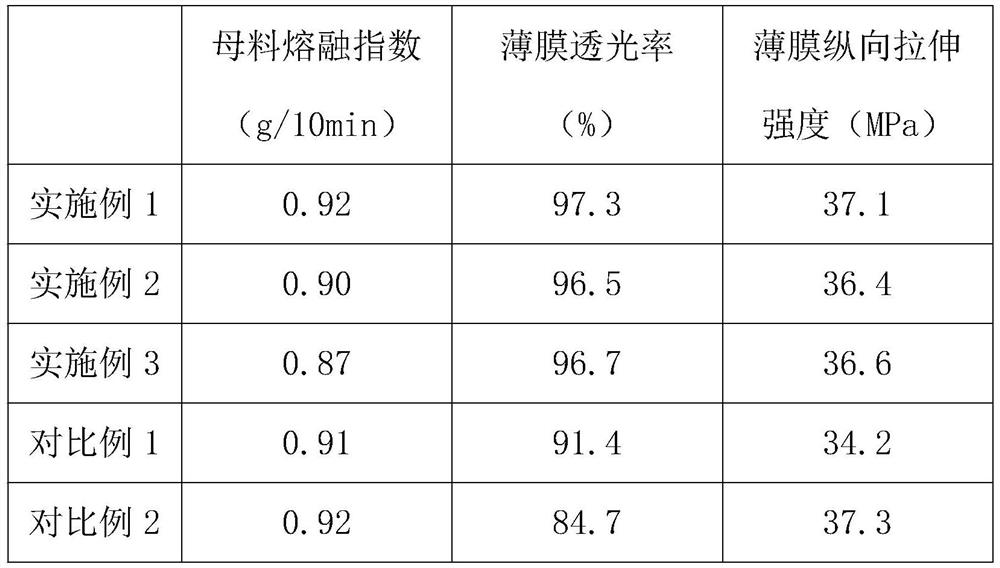

Examples

Embodiment 1

[0019] A composite barium sulfate filler masterbatch for transparent plastic filling, which is composed of the following ingredients in weight percent: 1.7% stearic acid, 1.5% coupling agent, 12% low-density polyethylene, 2.4% polyethylene wax, template modification Active agent 0.25% and the balance of barium sulfate.

[0020] The barium sulfate is a barium sulfate powder produced by a precipitation method with an average particle diameter of ≤0.2 μm and a powder whiteness of ≥98%. The coupling agent is a silane coupling agent. The template modifier is a composite material of glass fiber cotton and graphene film. The preparation method of described template modifier comprises the following steps:

[0021] A. Make superfine glass fiber cotton from ultrafine glass fibers with a diameter of 0.1-1 μm on the forming net;

[0022] B. Lay the pretreated graphene film on the ultrafine glass fiber cotton by electrostatic adsorption to form a composite film;

[0023] C. Cut the com...

Embodiment 2

[0028] A composite barium sulfate filler masterbatch for transparent plastic filling, which is composed of the following ingredients in weight percent: 2.0% stearic acid, 1.2% coupling agent, 20% low-density polyethylene, 1.8% polyethylene wax, template modification Active agent 0.3% and the balance of barium sulfate.

[0029] The barium sulfate is a barium sulfate powder produced by a precipitation method with an average particle diameter of ≤0.2 μm and a powder whiteness of ≥98%. The coupling agent is an aluminate coupling agent. The template modifier is a composite material of glass fiber cotton and graphene film. The preparation method of described template modifier comprises the following steps:

[0030] A. Make superfine glass fiber cotton from ultrafine glass fibers with a diameter of 0.1-1 μm on the forming net;

[0031] B. Lay the pretreated graphene film on the ultrafine glass fiber cotton by electrostatic adsorption to form a composite film;

[0032] C. Cut the ...

Embodiment 3

[0037] A composite barium sulfate filler masterbatch for transparent plastic filling, which is composed of the following components by weight percentage: 1.4% stearic acid, 1.8% coupling agent, 8% low-density polyethylene, 2.8% polyethylene wax, template modification Active agent 0.1% and the balance of barium sulfate.

[0038] The barium sulfate is a barium sulfate powder produced by a precipitation method with an average particle diameter of ≤0.2 μm and a powder whiteness of ≥98%. The coupling agent is a silane coupling agent or an aluminate coupling agent. The template modifier is a composite material of glass fiber cotton and graphene film. The preparation method of described template modifier comprises the following steps:

[0039] A. Make superfine glass fiber cotton from ultrafine glass fibers with a diameter of 0.1-1 μm on the forming net;

[0040] B. Lay the pretreated graphene film on the ultrafine glass fiber cotton by electrostatic adsorption to form a composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com