Sample pretreatment method for near-infrared detection of finished tobacco lamina

A sample pretreatment and near-infrared detection technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high manpower and material resources consumption, low efficiency, and long time consumption, so as to save drying time and shorten pretreatment time , the effect of meeting the requirements of near-infrared detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be understood that within the scope of the present invention, the above-mentioned technical features of the present invention and the technical features specifically described in the following (such as embodiments) can be combined with each other to form new or preferred technical solutions. Due to space limitations, we will not repeat them here. All technologies realized based on the above contents of the present invention belong to the scope of the present invention.

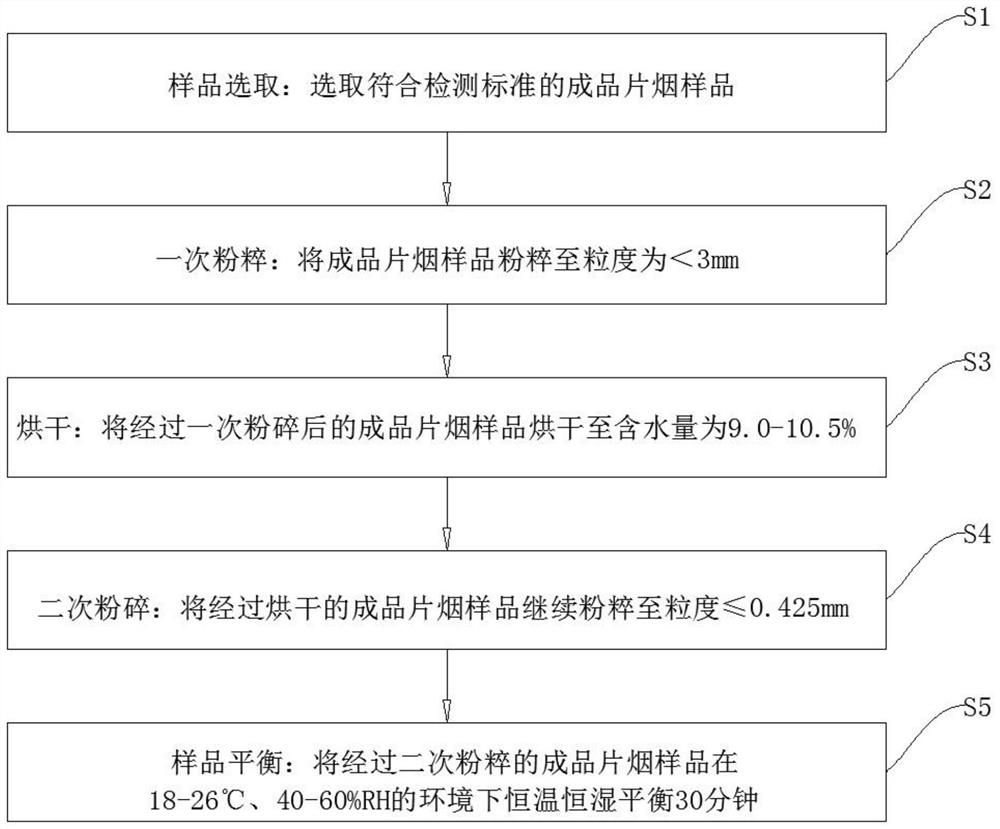

[0018] A kind of pretreatment method of finished product sheet smoke near-infrared detection sample, such as figure 1 shown, including the following steps:

[0019] S1 Sample selection: Select the finished tobacco samples that meet the testing standards; the specific process is: open the finished cigarette box, and sample at three points along the diagonal of the box.

[0020] S2 primary crushing: crushing the finished tobacco sample to a particle size of <3mm; in this example, a YMS-96 grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com