Cement storing and mixing equipment for construction site

A technology for construction sites and mixing equipment, which is applied to cement mixing devices, clay preparation devices, mixing operation control devices, etc., can solve problems such as affecting the bonding strength and reducing the compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] as attached figure 1 to attach Image 6 Shown:

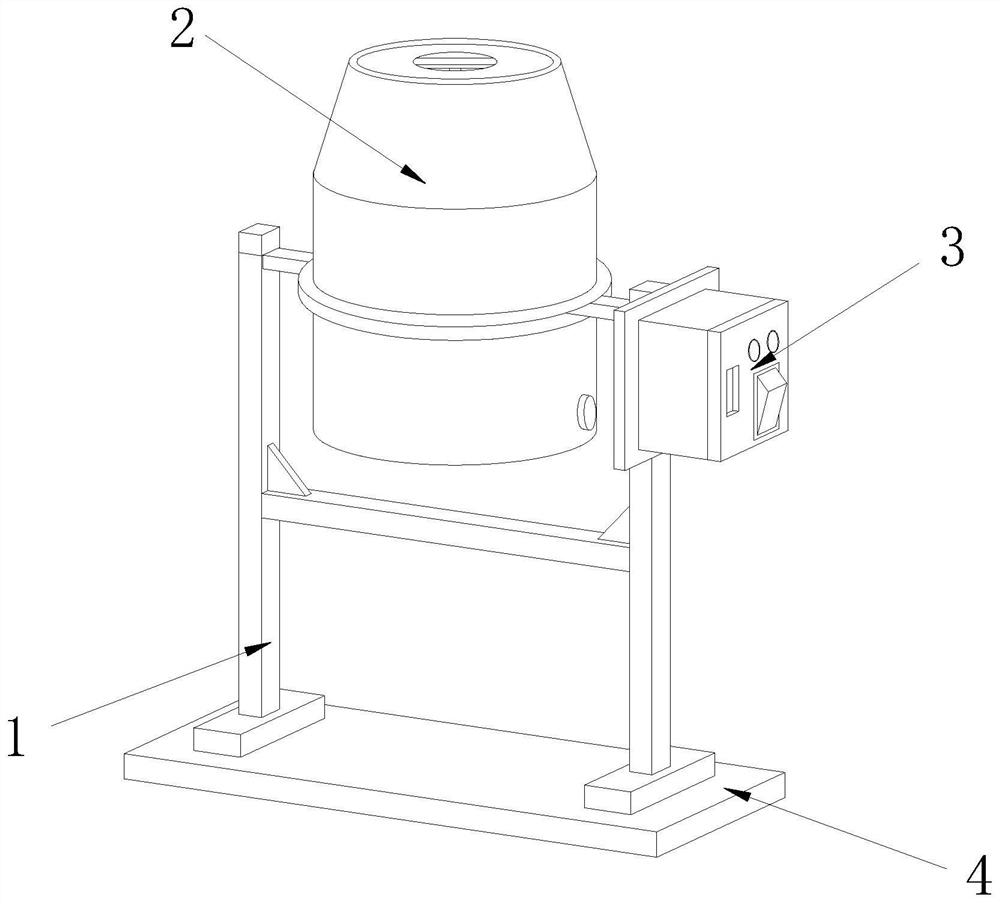

[0029] The invention provides a kind of cement storage and mixing equipment for construction site, its structure includes: support frame 1, tank body 2, control panel 3, base 4, the lower end surface of the support frame 1 is welded with the upper end surface of the base 4, the One side of the tank body 2 is embedded in the inner side of the support frame 1 , and the left end surface of the control panel 3 is bolted to the right end surface of the support frame 1 .

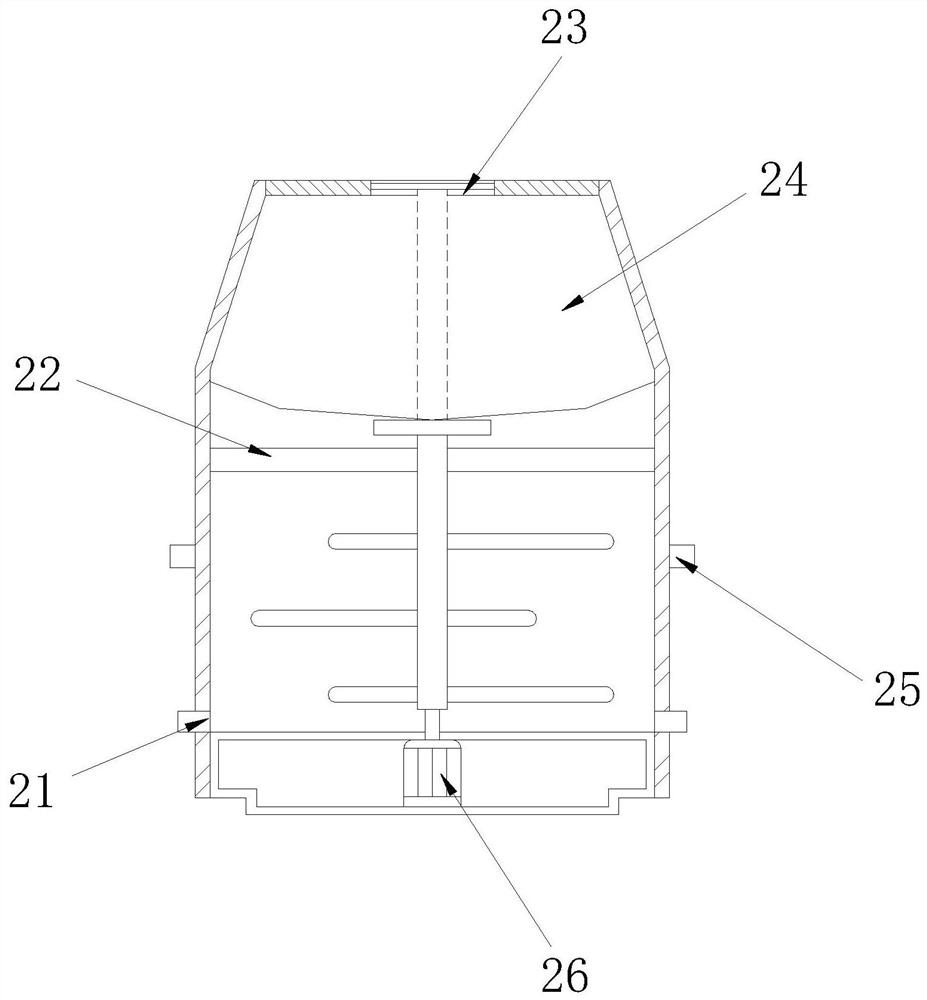

[0030] Wherein, the tank body 2 includes a discharge port 21, a support rod 22, a feed port 23, a stirring device 24, a support plate 25, and a driver 26, and one end of the discharge port 21 is embedded in the inside of the tank body 2, so The support rod 22 is mounted on the inside of the tank body 2, the feed port 23 and the tank body 2 are an integrated structure, the upper end of the stirring device 24 is movably engaged on the inside of the feed port...

Embodiment 2

[0038] as attached Figure 7 to attach Figure 9 Shown:

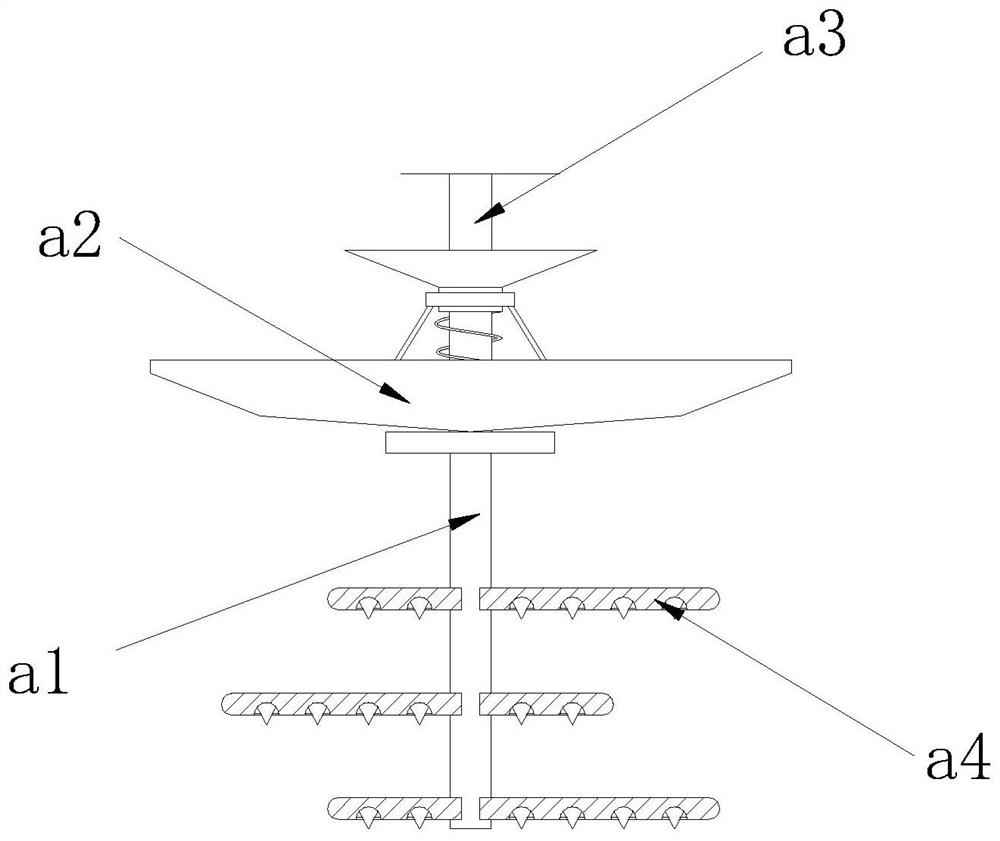

[0039] The present invention provides a cement storage and mixing equipment for a construction site, the connecting device d5 includes a swinging device e1, a connecting block e2, and a connecting plate e3, and the front end of the swinging device e1 is movable and engaged with the rear end of the connecting plate e3 , the connection block e2 is installed between the connection plates e3, and the swing device e1 is symmetrically distributed on both sides of the connection block e2, thereby increasing the shaking of the filter net d4, and better screening of raw materials can be carried out.

[0040] Wherein, the swing device e1 includes an arc-shaped rod h1, an auxiliary device h2, and a connecting rod h3. On both sides of the rod h3, the connecting rod h3 is made of rubber, so the connecting rod h3 has elasticity, driven by the auxiliary device h2, the connecting rod h3 will be able to swing.

[0041] Wherein, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com