Preparation method and application of heteropolyacid-modified metal-organic framework composite

A technology of metal-organic frameworks and heteropolyacids, applied in the direction of organic diaphragms, electrolytic components, electrolytic processes, etc., can solve the problems of limiting the loading of heteropolyacids on substrates and the loss of heteropolyacids, achieving good stability and improving The effect of proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

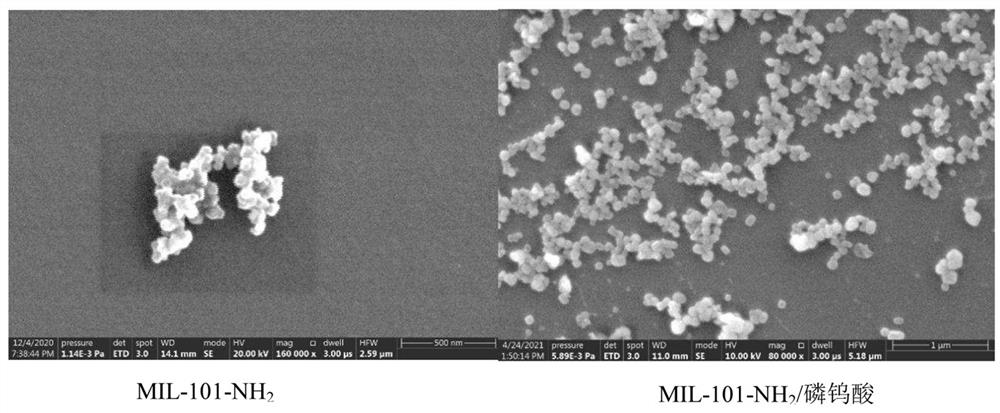

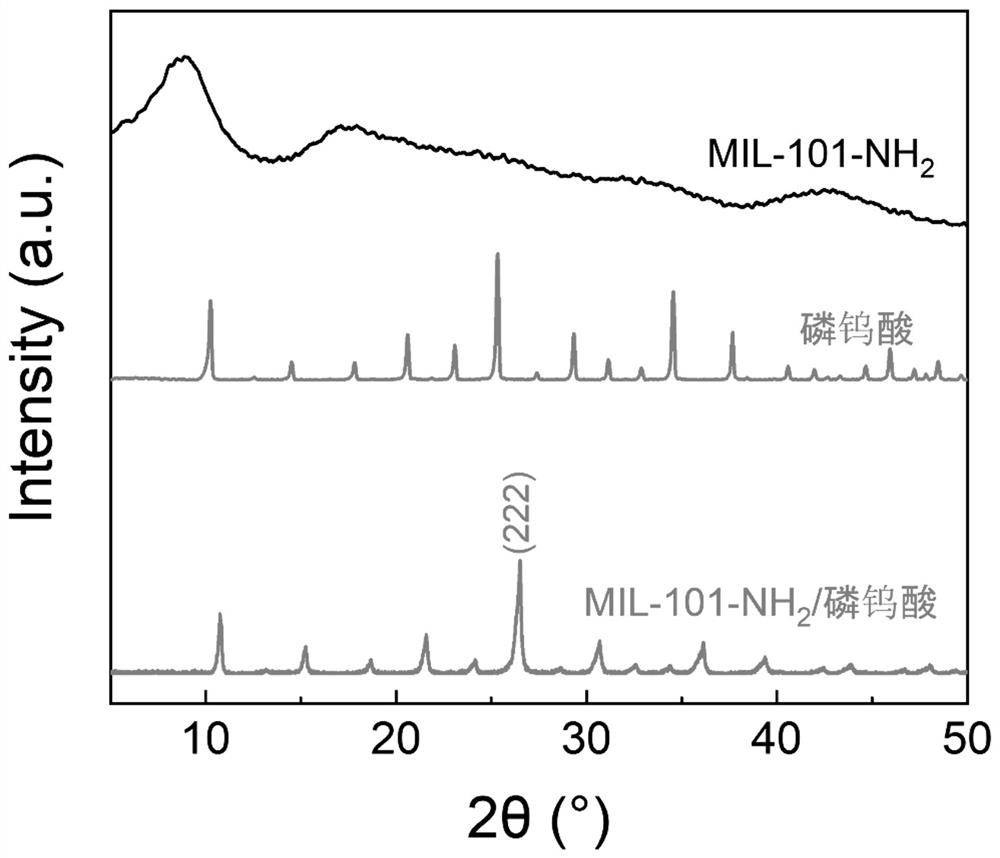

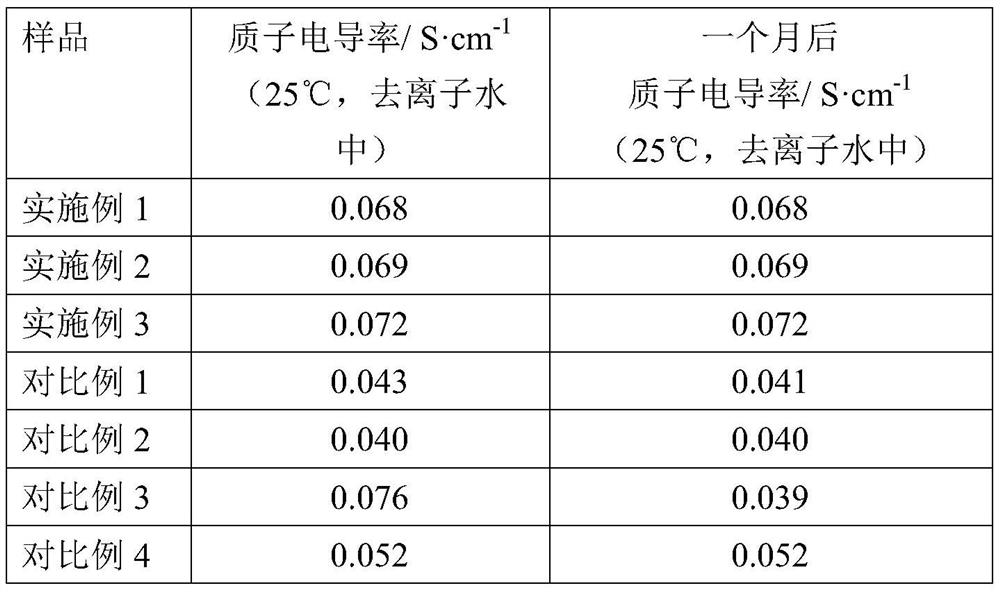

[0024] 1g of MIL-101-NH 2 Ultrasound in deionized water for 1h to obtain a suspension, then add 5g of phosphotungstic acid to the uniformly dispersed MIL-101-NH 2 In the suspension, stir for more than 24h. Then put the suspension in an oven and place it at 60°C for 24 hours to completely remove the water to obtain evenly dispersed MIL-101-NH 2 / Phosphotungstic acid powder. The powder was placed in the oven, first placed at 100°C for 12 hours, then heated to 275°C at a heating rate of 5°C / min, and kept for 5 hours. When the muffle furnace returned to room temperature, the crude UiO-66-NH 2 / Phosphotungstic acid powder.

[0025] Wash the prepared powder several times with water to remove unreacted phosphotungstic acid to obtain pure MIL-101-NH 2 / Phosphotungstic acid powder. Add 0.018g of powder into sulfonated polyetheretherketone (SPEEK) to ensure that the total mass is 0.3g. The aforementioned mixture was evenly dispersed in N,N-dimethylacetamide (DMAc), ensuring th...

Embodiment 2

[0028] 1g of UiO-66-NH 2 Sonicate in deionized water for 1h, then add 5g of silicotungstic acid into the uniformly dispersed UiO-66-NH 2 In the suspension, stir for more than 24h. Afterwards, the suspension was placed in an oven and placed at 60°C for 24 hours to completely remove the water to obtain uniformly dispersed UiO-66-NH 2 / Silicon tungstic acid powder. The powder was placed in the oven, first placed at 100°C for 12 hours, then heated to 275°C at a heating rate of 5°C / min, and kept for 5 hours. When the muffle furnace returned to room temperature, the crude UiO-66-NH 2 / Silicon tungstic acid powder. Wash the prepared powder several times with water to remove unreacted silicotungstic acid to obtain pure UiO-66-NH 2 / Silicon tungstic acid powder.

[0029]Add 0.018g of powder into sulfonated polyetheretherketone (SPEEK) to ensure that the total mass is 0.3g. The aforementioned mixture was evenly dispersed in N,N-dimethylacetamide (DMAc), ensuring that the mass ...

Embodiment 3

[0031] 1g of UiO-66-NH 2 Sonicate in deionized water for 1h, then add 9g of phosphotungstic acid into the uniformly dispersed UiO-66-NH 2 In the suspension, stir for more than 24h. Afterwards, the suspension was placed in an oven and placed at 60°C for 24 hours to completely remove the water to obtain uniformly dispersed UiO-66-NH 2 / Phosphotungstic acid powder. The powder was placed in the oven, first placed at 100°C for 12 hours, then heated to 275°C at a heating rate of 5°C / min, and kept for 5 hours. When the muffle furnace returned to room temperature, the crude UiO-66-NH 2 / Phosphotungstic acid powder. Wash the prepared powder several times with water to remove unreacted phosphotungstic acid to obtain pure UiO-66-NH 2 / Phosphotungstic acid powder.

[0032] Add 0.018g of powder into sulfonated polyetheretherketone (SPEEK) to ensure that the total mass is 0.3g. The aforementioned mixture was evenly dispersed in N,N-dimethylacetamide (DMAc), ensuring that the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com