Device and method for wear monitoring of shield hob based on topography of ballast

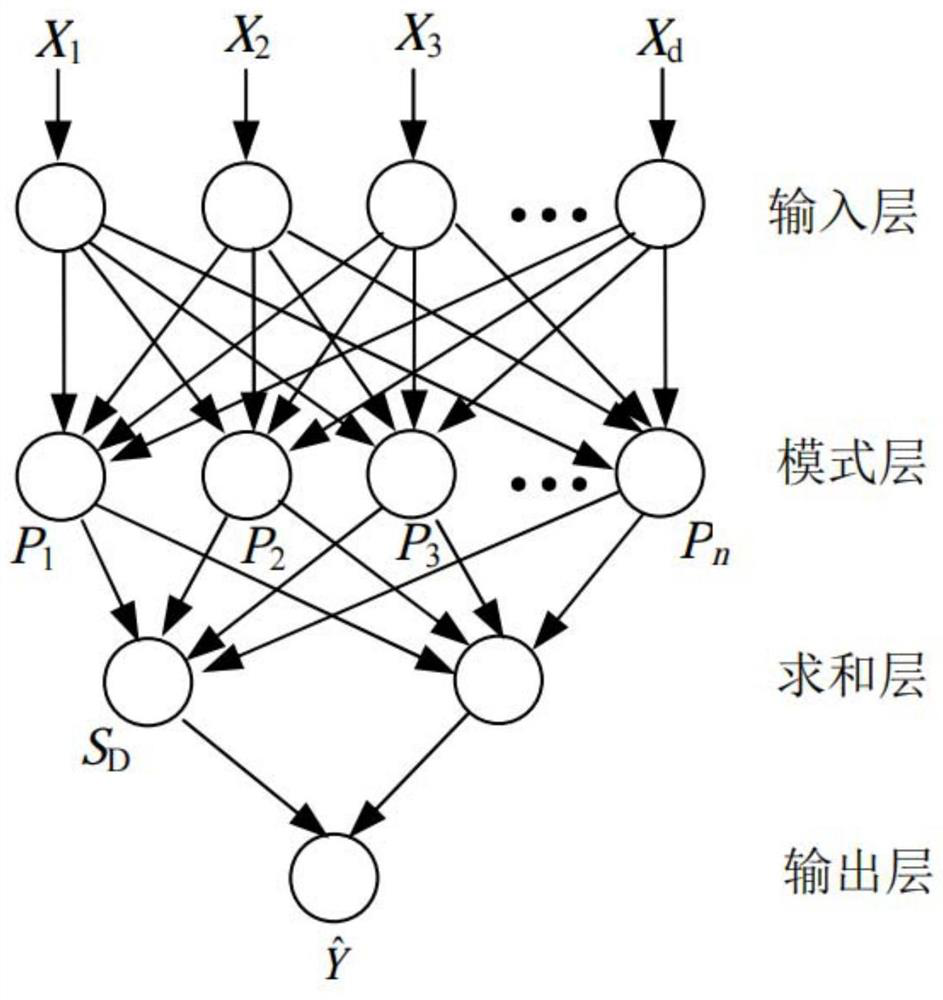

A hob and topography technology, which is applied to measuring devices, mining devices, optical devices, etc., can solve the problems of inability to accurately and accurately predict the wear amount of the hob, and the inability to meet the requirements of intelligent, safe and efficient tunneling of shield tunnels, and to improve accuracy. predicted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

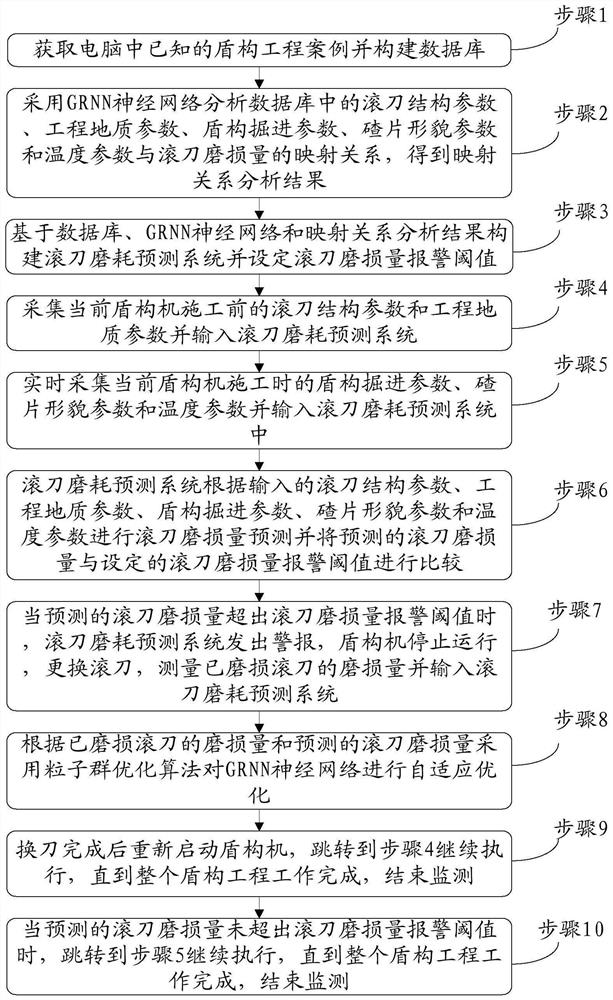

[0048] Aiming at the problems that the existing construction method cannot accurately and accurately predict the wear amount of the current hob, and cannot meet the requirements of the shield machine for intelligent, safe and efficient excavation, the invention provides a shield hob wear monitoring device based on the shape of the ballast piece. and methods.

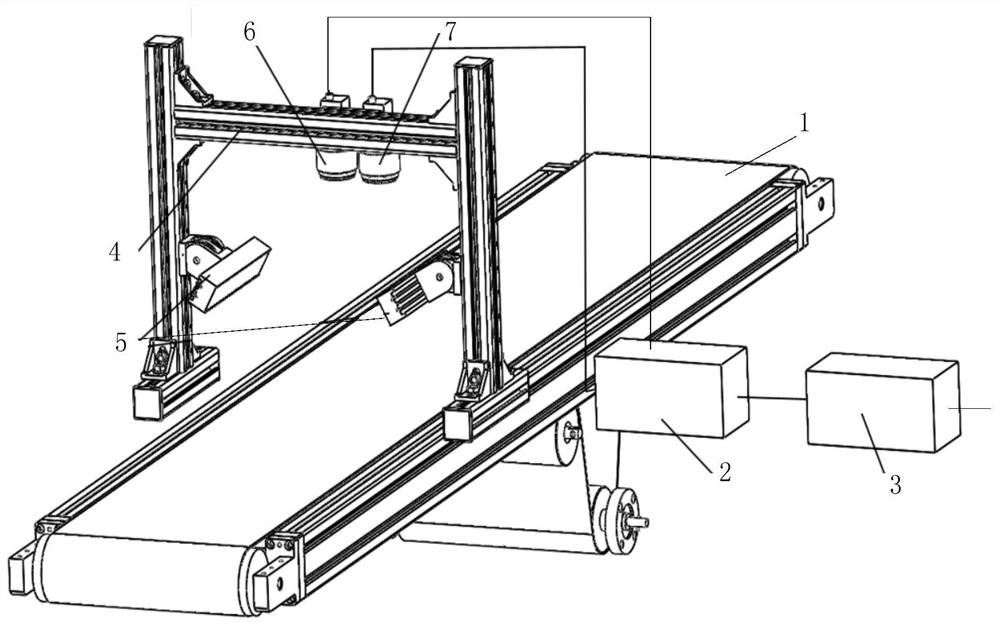

[0049] like Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a shield machine hob wear monitoring device based on the topography of the ballast piece, including: a data collection box 2, and the data collection box 2 is arranged on one side of the shield machine conveyor belt 1; Industrial computer 3, the industrial computer 3 is arranged on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com