Wire grid-based shield machine cutter abrasion loss on-line monitoring device

A shield machine tool and monitoring device technology, applied in the direction of measuring devices, electric devices, electromagnetic means, etc., can solve problems such as difficult maintenance, high wiring requirements, and inability to realize continuous monitoring, so as to prolong the safe service life and ensure Reliability, the effect of avoiding economic loss and personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. It should be noted that this embodiment is descriptive rather than restrictive, and should not limit the protection scope of the present invention.

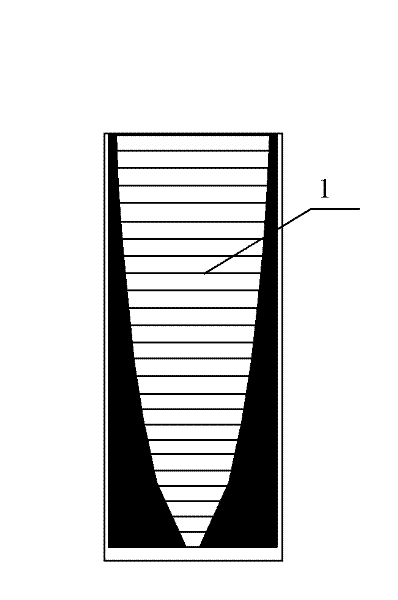

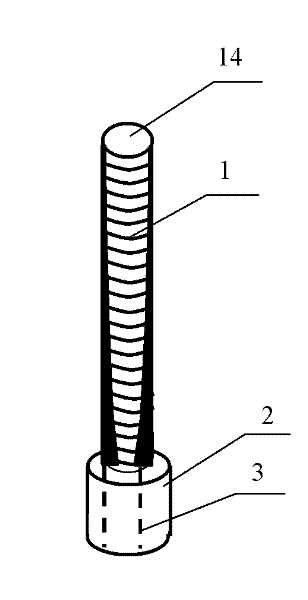

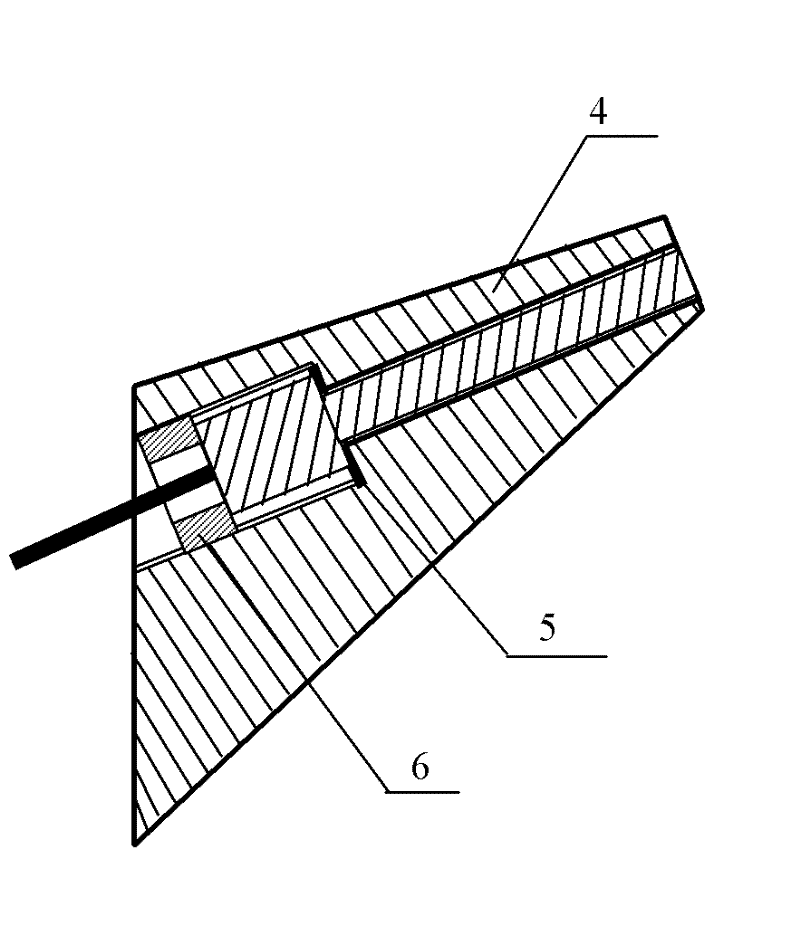

[0019] The wire grid-based on-line monitoring device for shield machine tool wear is composed of a resistance grid 1, a resistance grid base 2 and a resistance lead plug 3 to form a wire grid tool wear sensor ( figure 1 , figure 2 ). The wire grid type shield machine tool wear sensor is embedded in the tool 4 of the shield machine. The part where the resistance grid is in contact with the tool is filled with epoxy resin, the part where the resistance grid base 2 contacts the tool is provided with a rubber pad 5, and the resistance grid base 2 is fixed together with the tool through a lock nut 6 ( image 3 ). A signal amplifier 8 is provided on the cutterhead 7; a transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com