Silicon carbide flaw detection equipment

A defect detection, silicon carbide technology, applied in optical testing of defects/defects, measuring devices, material analysis by optical means, etc., can solve the problems of laborious and inaccurate detection, and achieve the effect of convenient detection and accurate detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

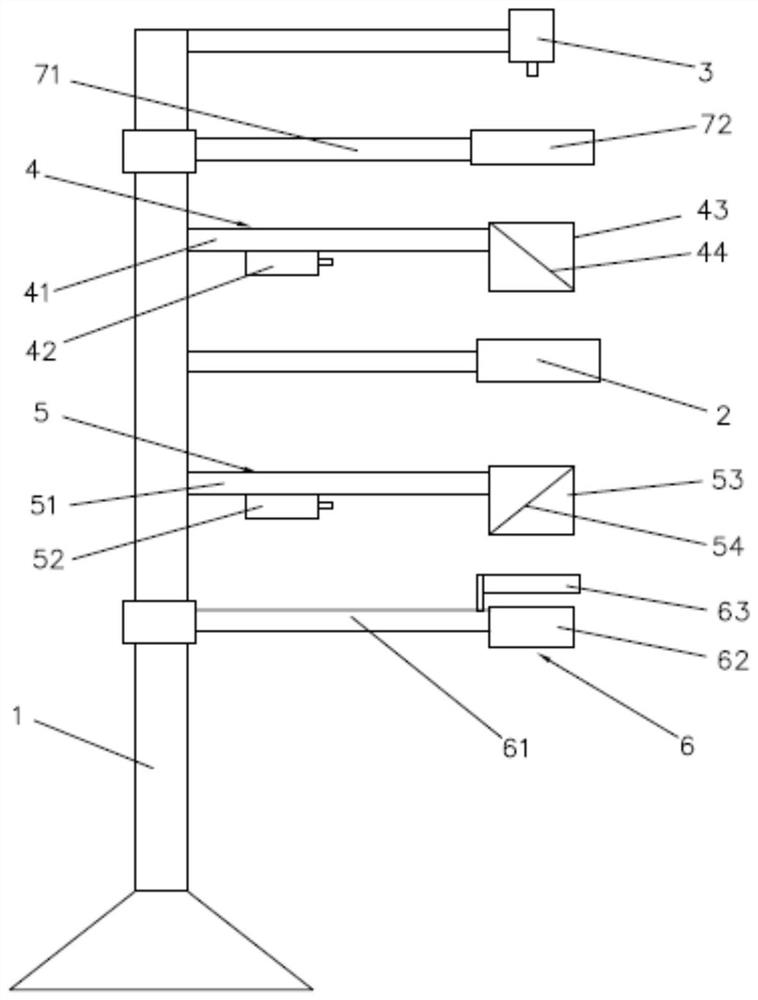

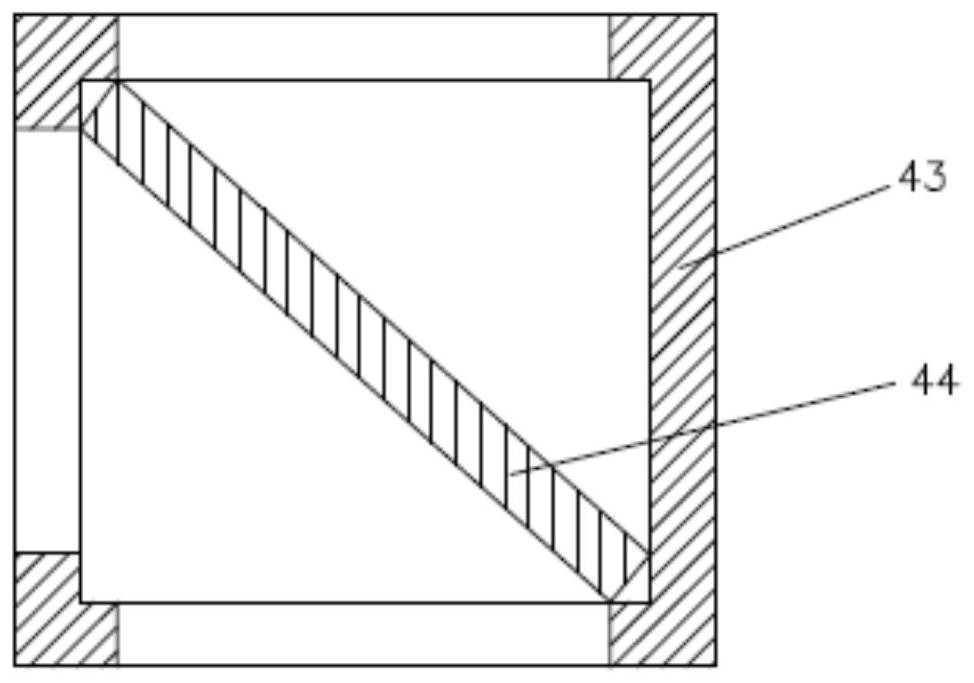

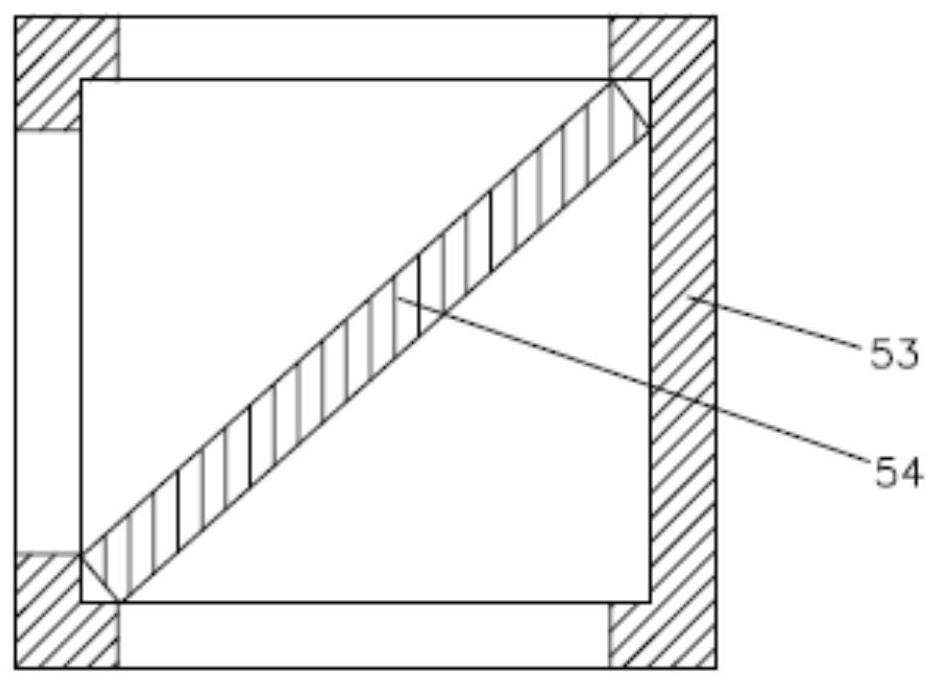

[0023] A silicon carbide defect detection device, such as Figure 1-3 As shown, it includes a support frame 1, a support rod is fixedly connected to the upper end of the support frame 1, and an imaging device is fixedly connected to the support rod. The imaging device can be a camera, or a combination of a camera and some lenses. The imaging device used in the present invention for camera 3. In addition, a bearing rod is fixedly connected to the middle part of the support frame 1, and a loading platform 2 is fixedly connected to the loading rod. The loading platform 2 is made of a transparent material, and the camera 3 is located directly above the loading platform 2. A through hole is provided, and the camera 3 can be used to photograph the situation of the stage 2 coming out. The position where the support frame 1 is located between the camera 3 and the stage 2 is provided with a first light source 4 directed toward the stage 2, and the position where the support frame 1 is...

Embodiment 2

[0034] A silicon carbide defect detection device, the difference from Embodiment 1 is, such as Figure 5 As shown, the device is not provided with a separate polarized light source, and a second camera 8 is provided at the position where the support frame 1 is located below the stage 2, and the second camera 8 is fixedly connected to the support frame 1 through a connecting rod. The illuminating end of the second camera 8 faces the central position of the stage 2, and the second camera 8 is below the transmitted light source 5; in addition, a third polarizer 9 is arranged between the transmitted light source 5 and the stage 2, and the third polarizer 9 is connected to the support frame 1 through a fixed rod, and the fixed rod can move around the support frame 1 to make it move to other positions. In this way, when detecting the lower surface of the silicon carbide substrate sheet, the reflected light after the transmission light source 5 is irradiated to the back surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com