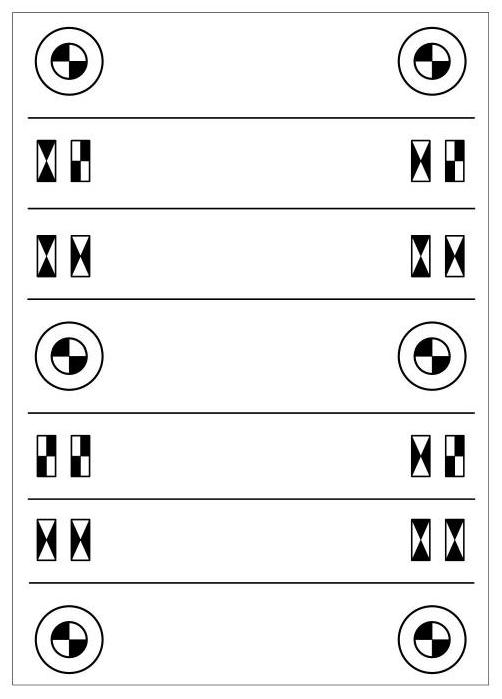

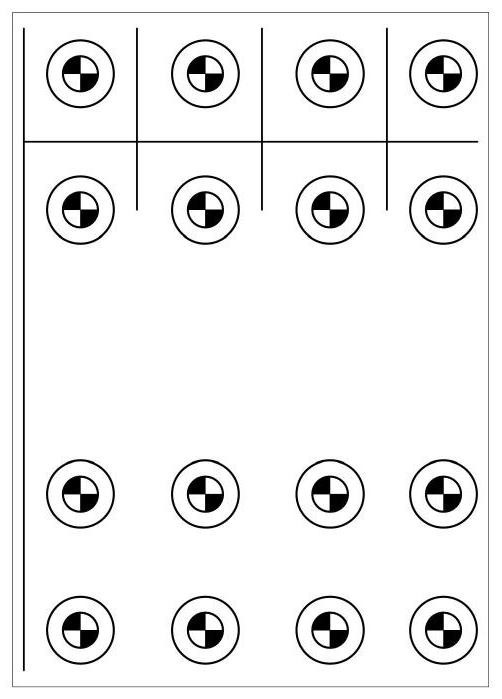

Camera calibration board and use method thereof, and feature point extraction method for camera calibration

A camera calibration and calibration board technology, applied in image analysis, image enhancement, instruments, etc., can solve the problems of mutual confusion, incomplete extraction, and poor matching between feature point image coordinates and spatial coordinates, and achieves the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

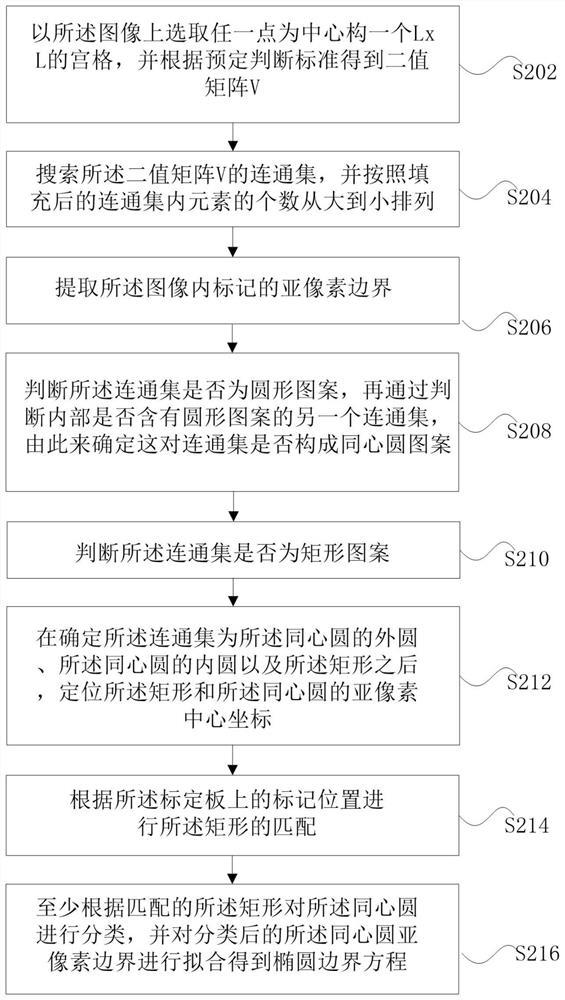

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

[0024] It should be noted that the steps shown in the flowcharts of the accompanying drawings may be performed in a computer system, such as a set of computer-executable instructions, and that although a logical order is shown in the flowcharts, in some cases, The steps shown or described may be performed in an order different than here.

[0025] In related technologies, the focal length of the camera may change continuously and unknown. At this time, when there is only pixel information, there is no good method to determine the five internal parameters of the camera based on a single ordinary camera, a single photo and a three-dimensional calibration template. Camera calibration is perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com