Demister flushing water recycling system and method

A technology of mist eliminator and water circulation, which is applied to chemical instruments and methods, cleaning methods using liquids, separation methods, etc. The effect of water balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

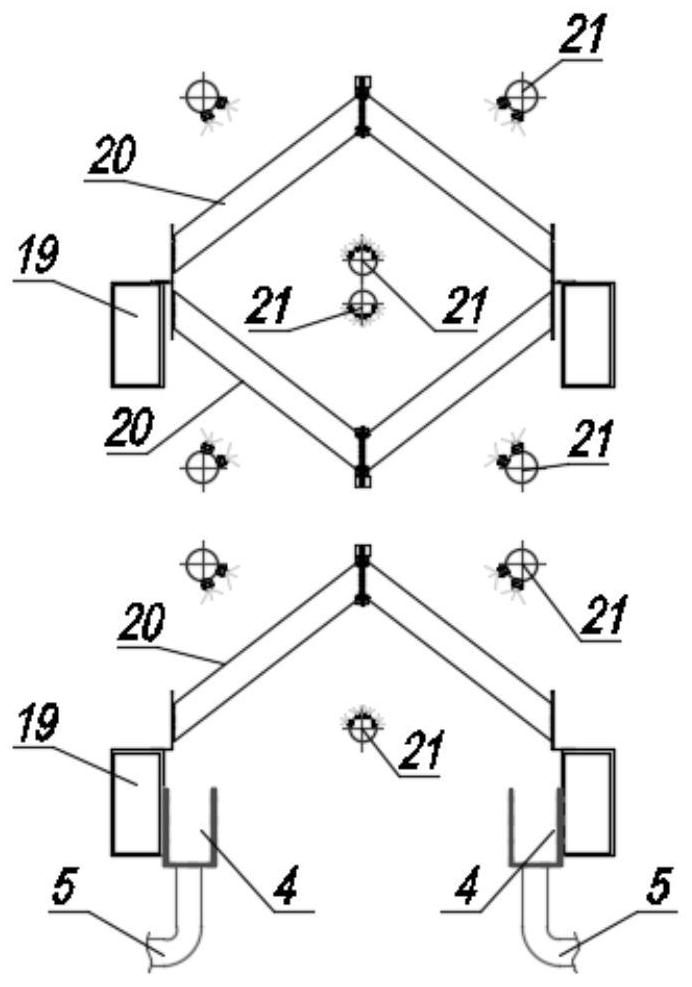

[0045] refer to figure 2 , the first layer of mist eliminator 20 and the third layer of mist eliminator 20 are roof structure, and arranged on the support beam 19 of the bottom layer of mist eliminator, the second layer of mist eliminator 20 are inverted roof structure, and The three layers of demisters 20 are jointly arranged on the upper support beam 19 of the demister;

Embodiment 2

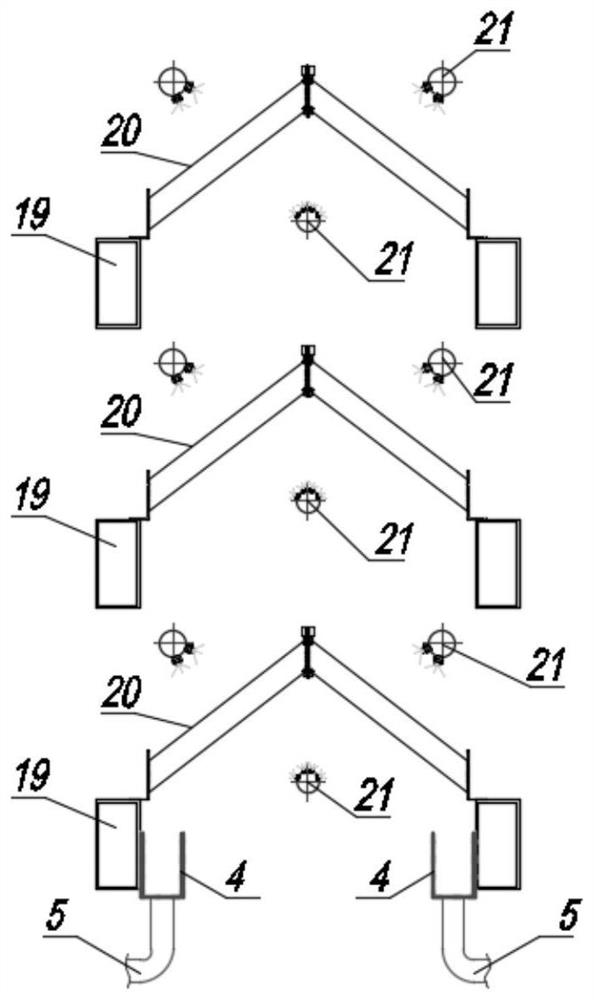

[0047] refer to image 3 , the three-layer mist eliminators 20 are all roof-ridge structures, respectively arranged on the three-layer mist eliminator support beams 19;

[0048] Main features of the present invention are:

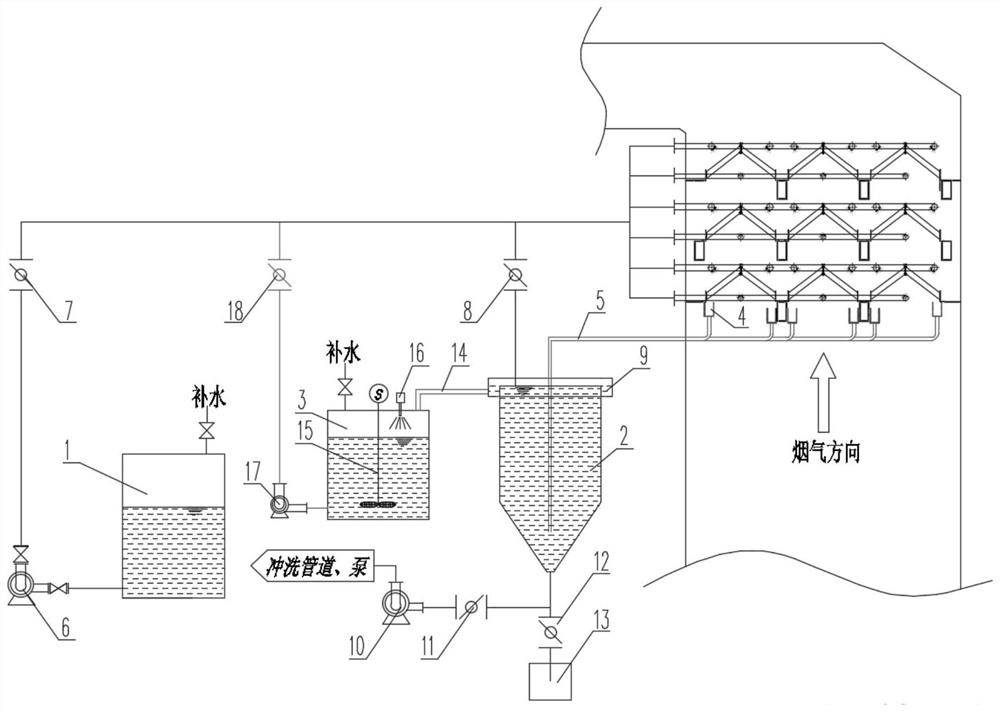

[0049] The present invention utilizes the demister flushing water collection tank 4 to collect the demister 20 flushing water to the clarified water tank 2, the clarified clear water circulates to flush the demister 20, and the turbid water at the bottom of the clarified water tank 2 flushes the desulfurization system pipeline, pump or discharges to The desulfurization island drainage pit 13 achieves the purpose of recycling the flushing water of the demister 20 in the simplest and feasible way, solves the problem of water balance in the desulfurization system of most units, and obtains the following effects at the same time:

[0050] When the mist eliminator 20 is flushed intermittently, the present invention can increase the frequency of flushing the mist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com