A compound manufacturing method of adding and subtracting materials for gradient function vibration and noise reduction composite materials

A composite material, vibration reduction and noise reduction technology, applied in the directions of additive manufacturing, additive processing, energy efficiency improvement, etc., can solve the problems of precise control, difficult composition and structure, difficult mechanical properties and functional characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

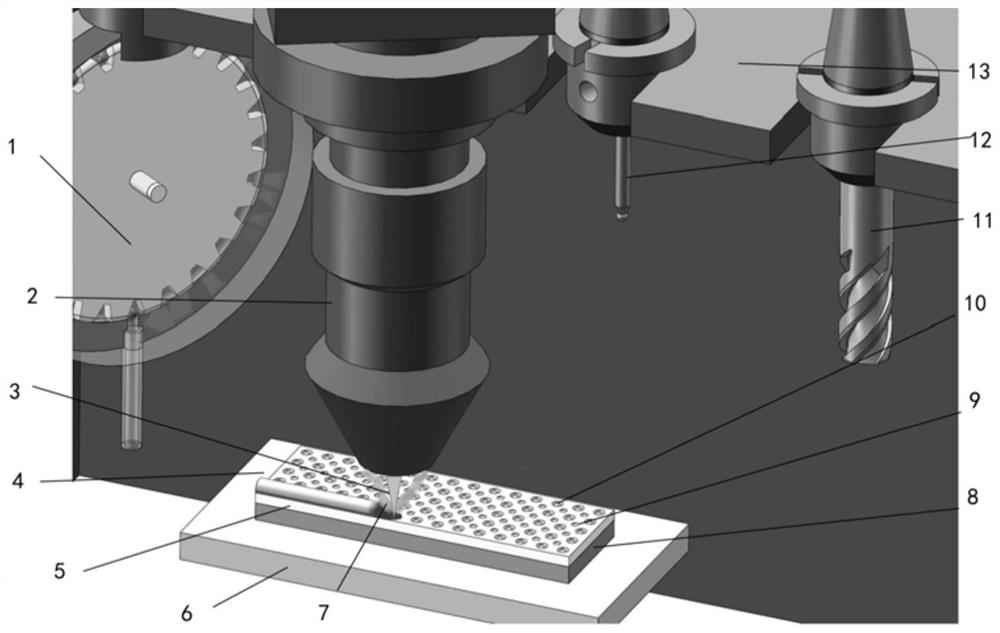

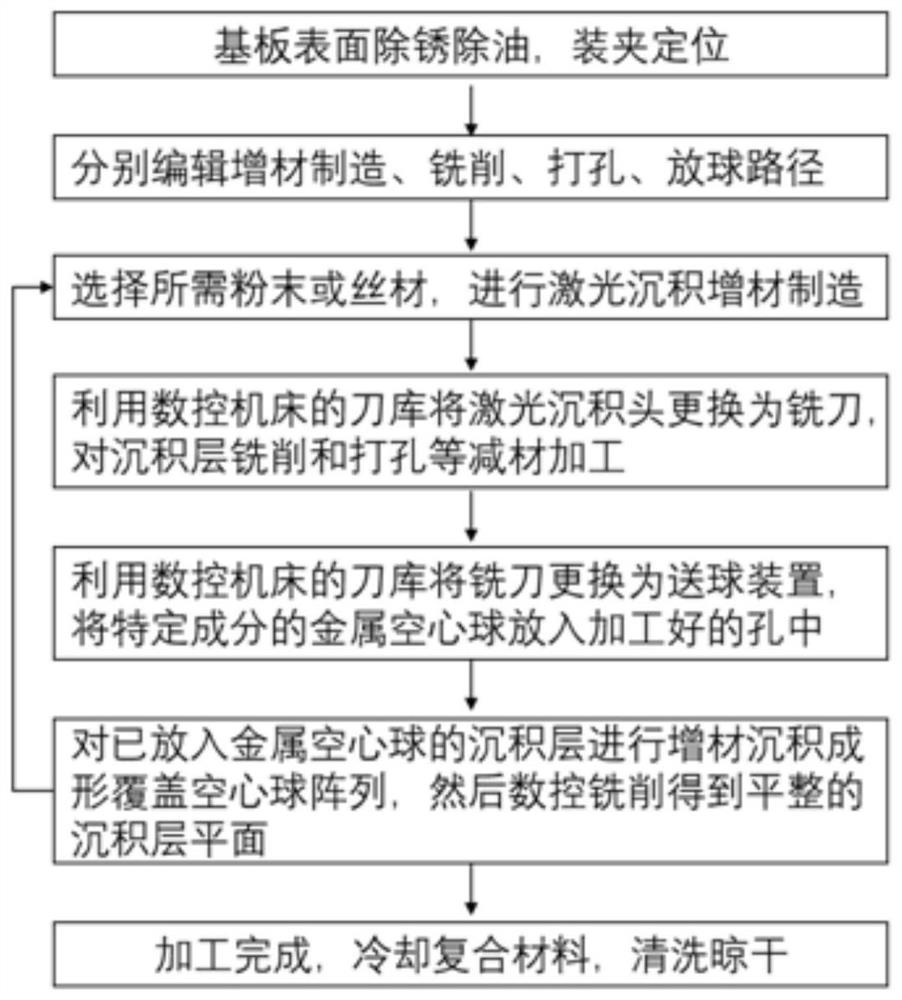

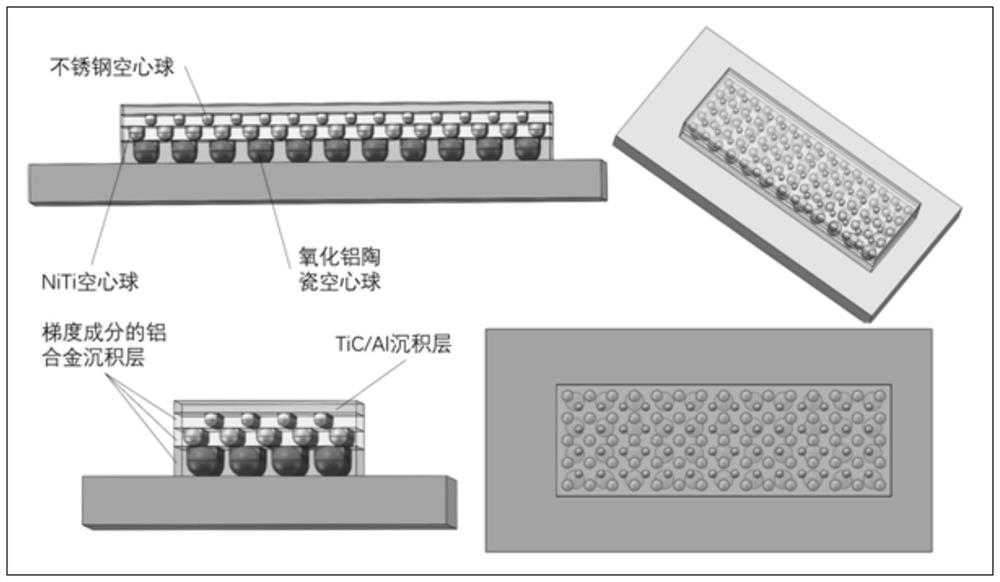

[0028] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0029] The present invention proposes a composite manufacturing method of adding and subtracting materials of a composite material with a gradient function for vibration reduction and noise reduction. The advanced composite precision manufacturing technology of adding and subtracting materials is used to manufacture a metal hollow sphere composite material with a gradient function; this innovative design makes full use of the increased "components can be controlled" and "structure can be designed" for material manufacturing, "high quality" and "high precision" for subtractive manufacturing, "energy absorption", "vibration and noise reduction", "heat insulation" for metal hollow sphere composite materials ” and other characteristics, the composition and structure of the vibration and noise reduction composite material can be controlled, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com