A spring end face grinder and a spring manufacturing process using the grinder

A grinding machine and frame technology, which is applied in the direction of manufacturing tools, grinding machine parts, grinding workpiece supports, etc., can solve the problem of low work efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-6 The application is described in further detail.

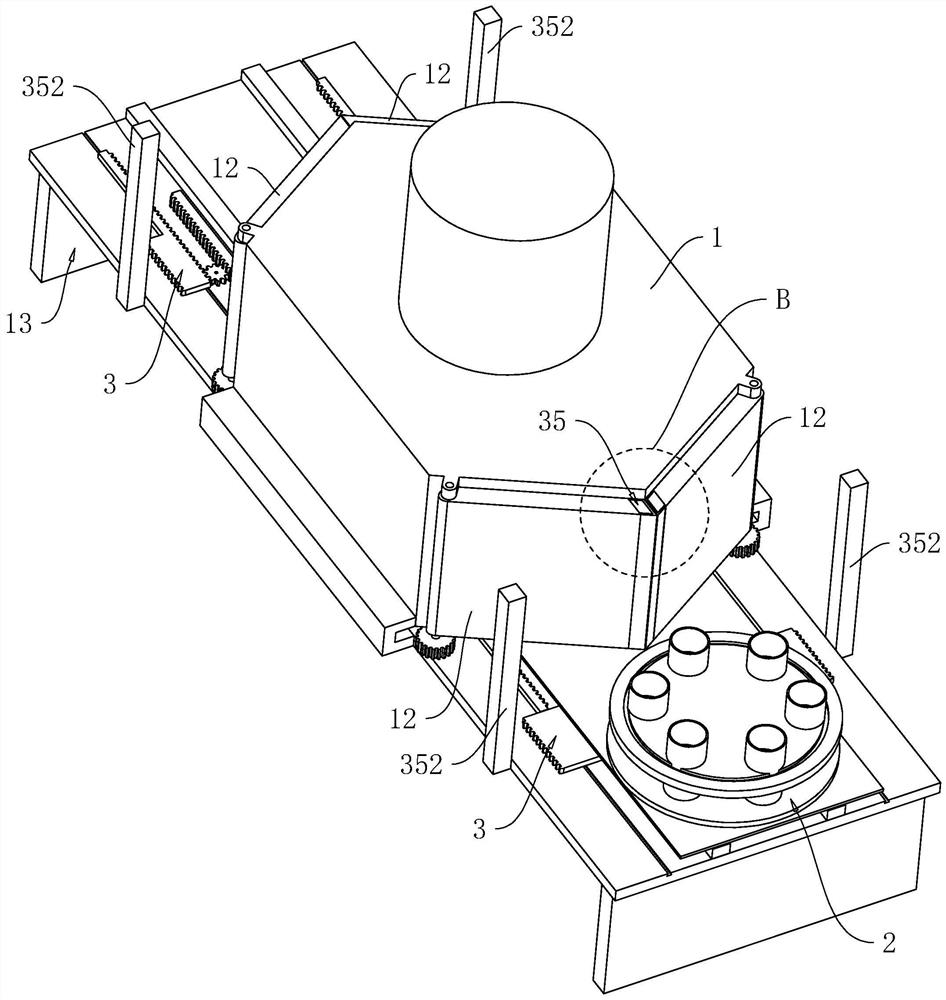

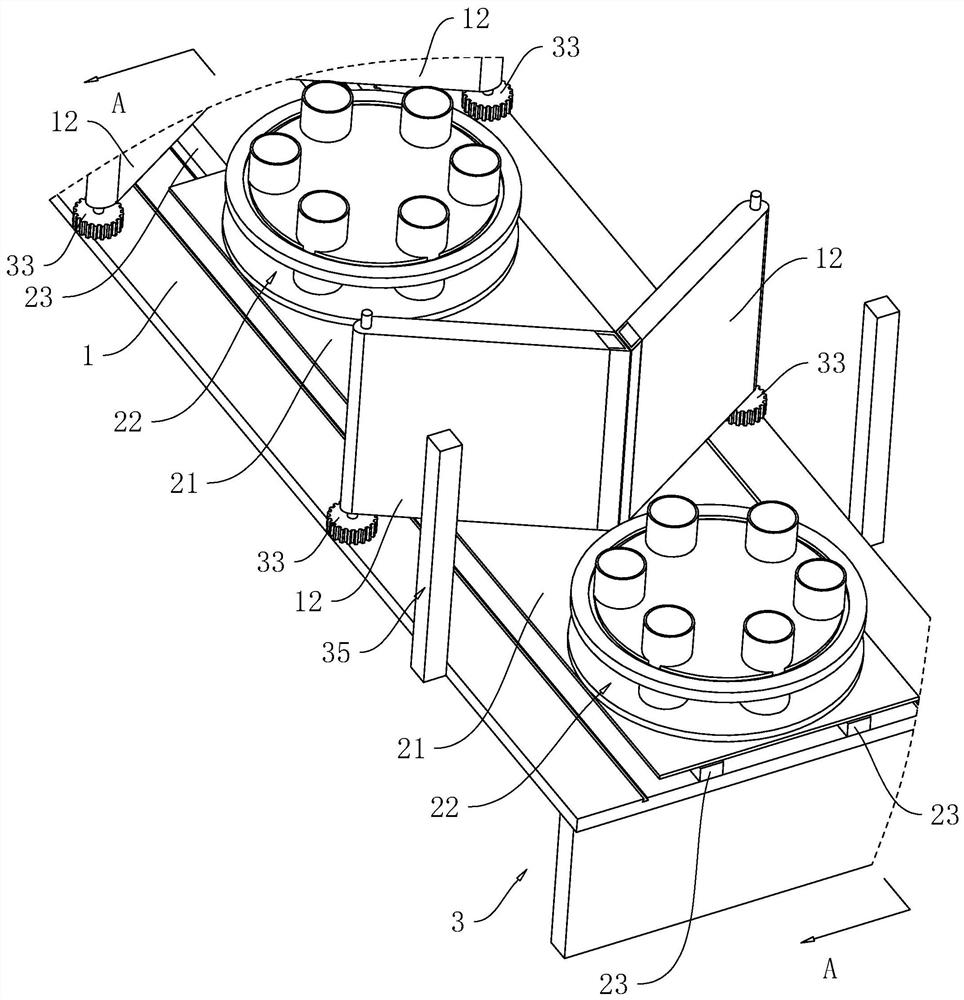

[0047] The embodiment of the present application discloses a spring end face grinder. refer to figure 1 , a spring end face grinder includes a frame 1, a feed channel 11 extending along the horizontal direction is provided on the frame 1, the two ends of the feed channel 11 run through the frame 1, and the frame 1 is provided with a feeding assembly 2, the frame 1 is rotatably connected with two blocking doors 12 for covering and closing both ends of the feeding passage 11.

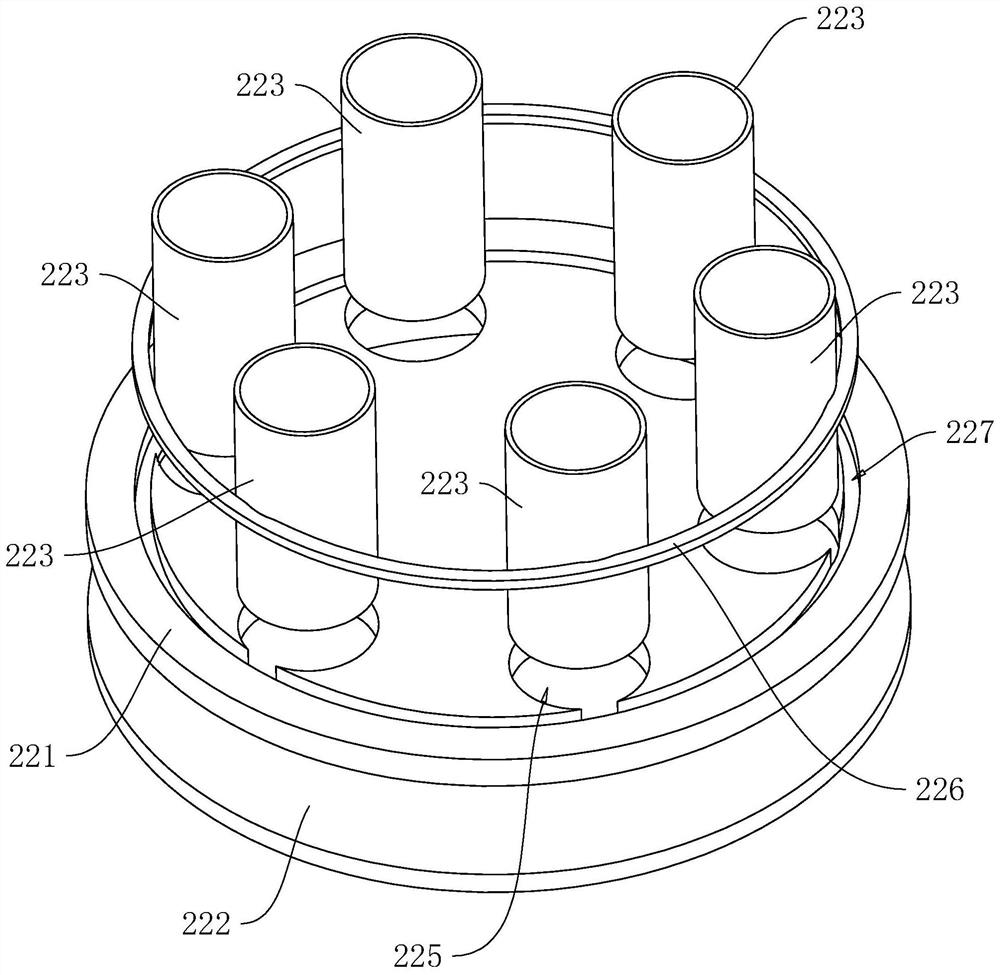

[0048] refer to figure 1 as well as figure 2 , the feeding assembly 2 includes a sliding plate 21, two placement racks 22 for placing springs and a driving piece for driving the sliding plate 21 to move; the driving piece includes two rodless cylinders 23, and two rodless cylinders 23 The length direction is parallel to the length direction of the feeding channel 11, and the two rodless cylinders 23 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com