Tire

A tire and tire circumferential technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of affecting the pattern, destroying the rubber, easy to fall out of stones, etc., to maintain uniformity and increase The effect of stone removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

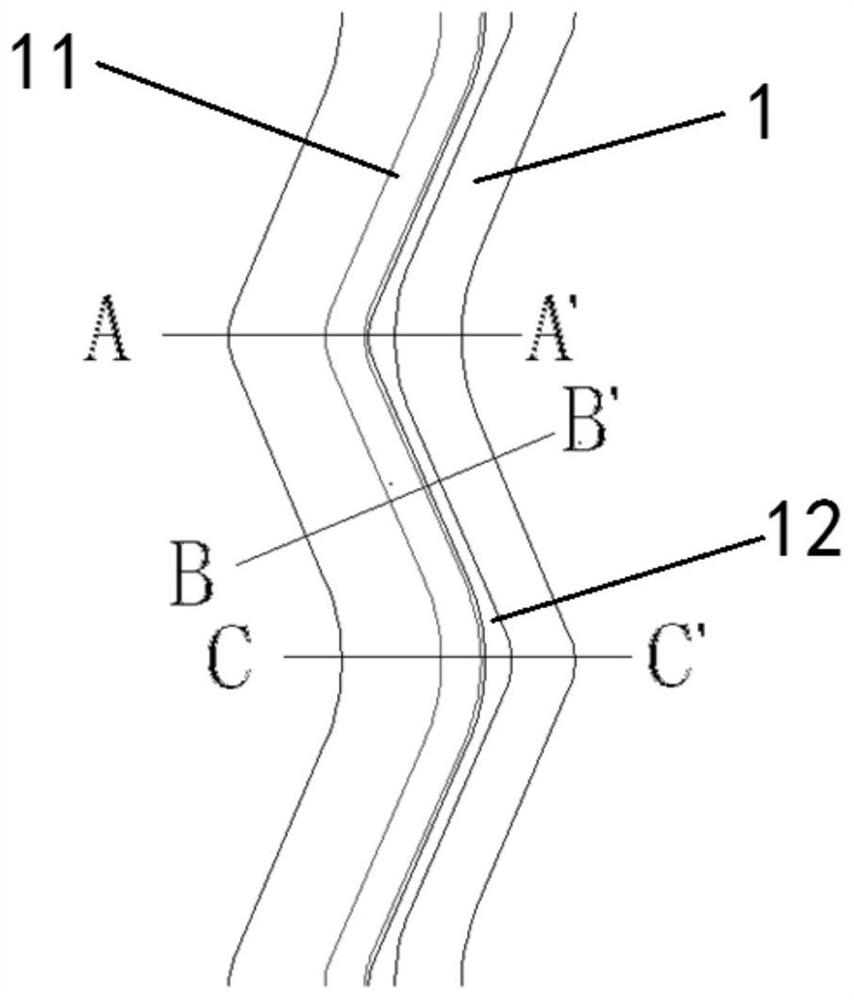

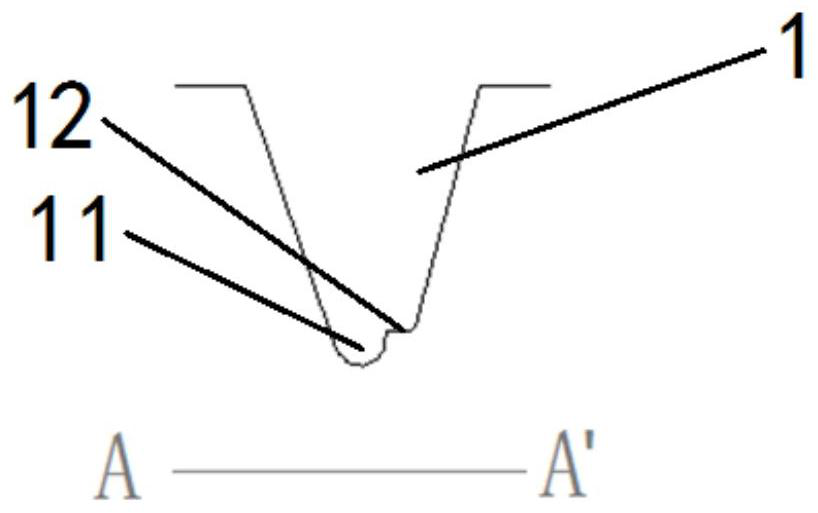

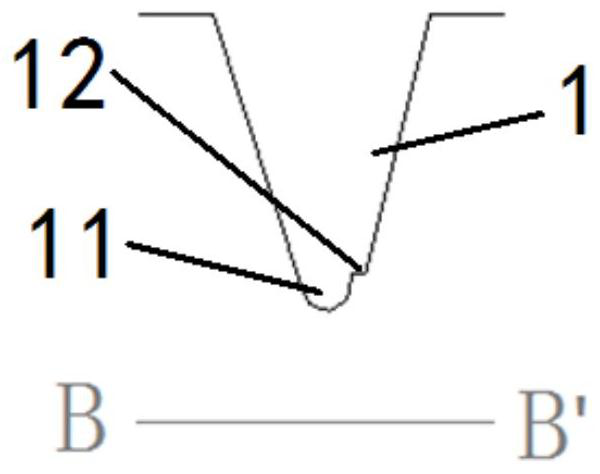

[0023] Such as figure 1 The profile of a zigzag longitudinal groove 1 shown in the figure, the left side of the figure is close to the tire shoulder, and the right side is close to the centerline of the tire circumference. The groove bottom 11 shown in the figure is in a state before rounding, Figure 2~4 for figure 1 A schematic cross-sectional view of a zigzag longitudinal groove shown in FIG.

[0024] Such as Figure 1~4 As shown, the twists and turns of pattern groove 1 are connected by arcs, and the sizes of the arcs on both sides are different, so that the surface width of pattern groove 1 at the turn is greater than the surface width of pattern groove 1 straight line, and the maximum surface width at the turn is the same as the minimum surface of the straight line. The ratio range of the width is 1.1-1.3, and it is 1.15 in this embodiment.

[0025] The inclination angles of the sidewalls on both sides of the groove 1 show a changing trend along the tire circumferenti...

Embodiment 2

[0029] Such as Figure 5 The profile of a zigzag longitudinal groove 1 shown in the figure, the left side of the figure is close to the tire shoulder, and the right side is close to the centerline of the tire circumference. The cross-sectional schematic diagram is similar to embodiment 1.

[0030] Such as Figure 5 As shown, the zigzag part of the groove 1 is connected by a straight line, and the straight lines on both sides are of different lengths, so that the surface width of the zigzag part of the groove is greater than the surface width of the straight line of the groove, and the ratio range of the maximum surface width of the zigzag part to the minimum surface width of the straight line Is 1.1-1.3, the present embodiment is 1.13, other features and dimensions are similar to embodiment 1.

Embodiment 3

[0032] A tire, including a tire running surface and a tire pattern arranged on the tire running surface, the tire pattern includes four zigzag longitudinal grooves 1 arranged along the tire circumference, the maximum surface width of the groove 1 at the zigzag part and the minimum surface of the straight line The width ratio range is 1.1, the sidewall inclination angle at the middle position of the straight line segment is relatively large, the difference range between the maximum inclination angle and the minimum inclination angle of each side wall is 3°, and the average value of the sidewall inclination angle on the side of groove 1 close to the tire shoulder It is greater than the average sidewall inclination angle on the side close to the tire circumferential centerline, and the difference range between the average sidewall inclination angles on both sides is 2°.

[0033] In this embodiment, the height of the groove bottom platform 12 from the groove bottom 11 is 5 mm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com