A winding machine for tin phosphor bronze strip and production process using the winding machine

A technology of tin-phosphorus bronze strip and winding machine, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., and can solve the problems of high disassembly and operation pressure, large individual, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

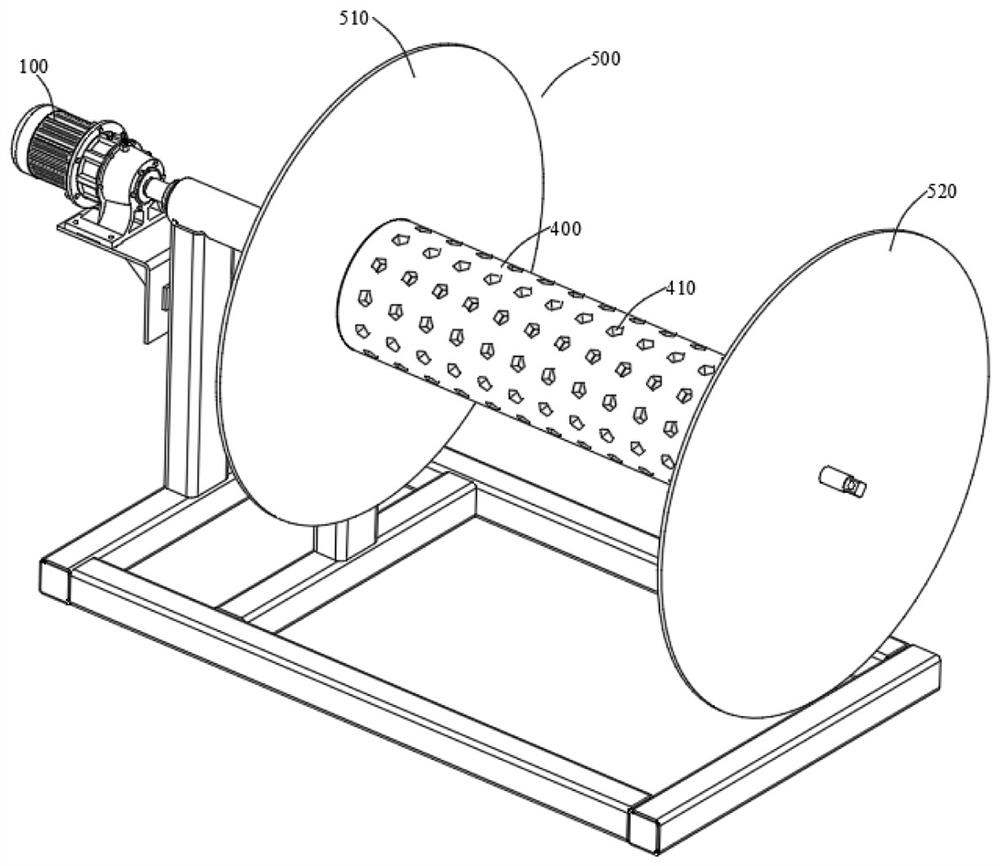

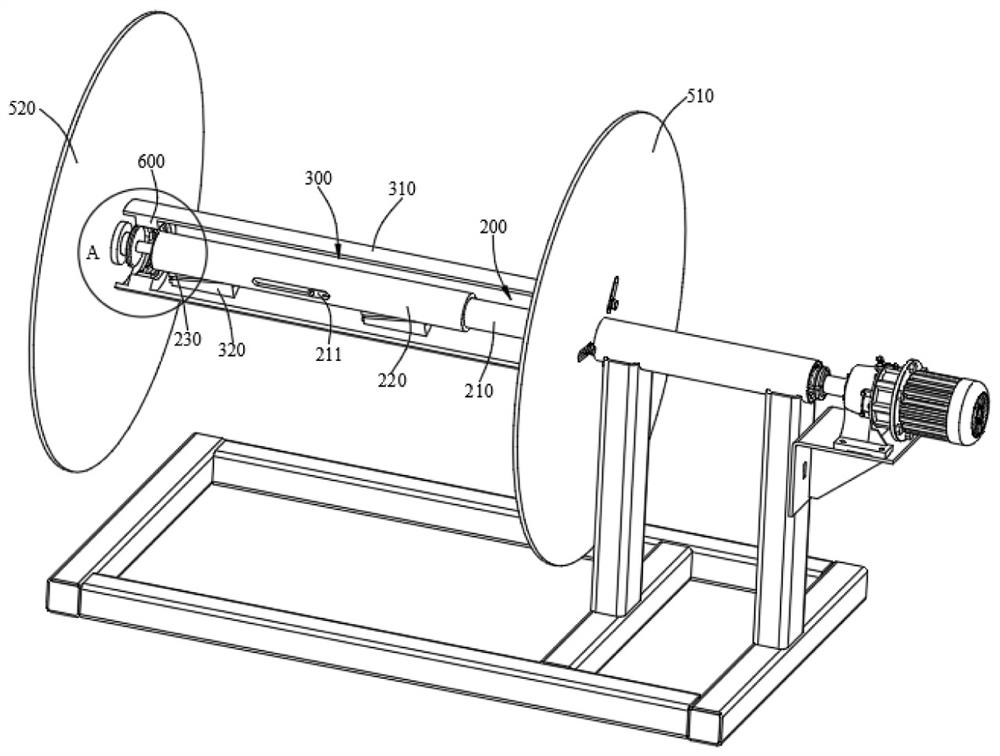

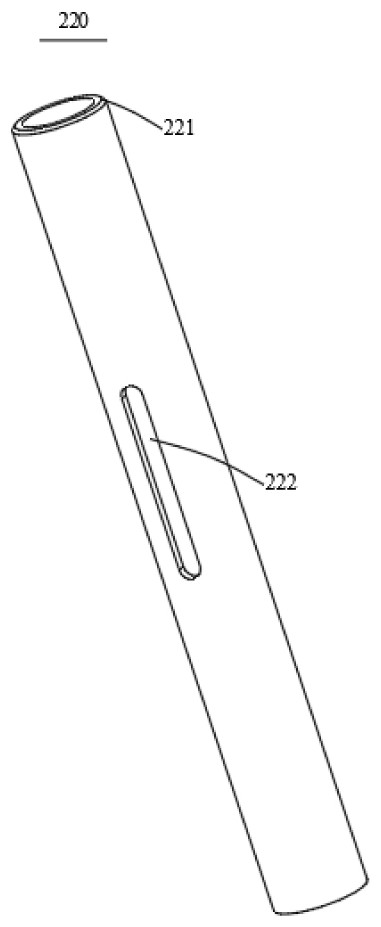

[0057] Such as Figures 1 to 9As described above, the embodiment of the present invention provides a winding machine for tin phosphor bronze strips, including: a driving motor 100, the end of the output shaft of the driving motor 100 is fixed with a driving part 200; several outer support parts 300, the The outer support part 300 is arranged around the driving part 200, and several of the outer support parts 300 are distributed in a ring shape; the outer sleeve 400 has a mesh 410 in the circumferential direction of the outer sleeve 400, and the outer sleeve 400 sets Set on the annular body formed by several of the outer support parts 300; the block part 500, the block part 500 includes the first block 510 fixed on one side of the several outer support parts 300 respectively and the The second blocking piece 520 on the other side of the outer support part 300 ; several clamping parts 600 , each clamping part 600 is located in one of the outer support parts 300 . Wherein the dr...

Embodiment 2

[0078] The present invention also provides a production process using the above winder, including, S1, setting the outer sleeve 400 outside the plurality of outer support parts 300; S2, driving the driving motor 100 to drive The driving part 200 rotates to wind the tin phosphor bronze strip on the outer sleeve 400 and form a single-layer full coverage on the outer wall of the outer sleeve 400; S3, insert the second blocking piece 520 on several Inside the outer support part 300; S4, drive the driving part 200 to drive several of the outer support parts 300 to expand outward to tighten the outer sleeve 400 and clamp the second blocking piece 520; S5. Continue to drive the drive motor until the multi-layers are fully wound.

[0079] In addition, the production process of the winding machine further includes S6, feeding cooling gas into the inlet 523 .

[0080] The production process using the winding machine has the characteristics of fast winding process and good winding effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com