Flying disc type full-automatic winding machine and winding method thereof

A fully automatic winding machine, flying disc technology, applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problems of unstable product quality, decreased motor quality, large waste, etc. quality, and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

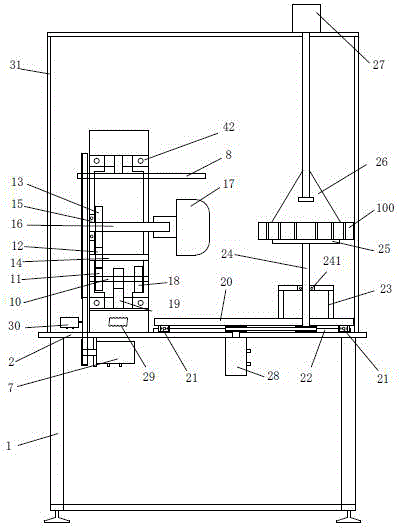

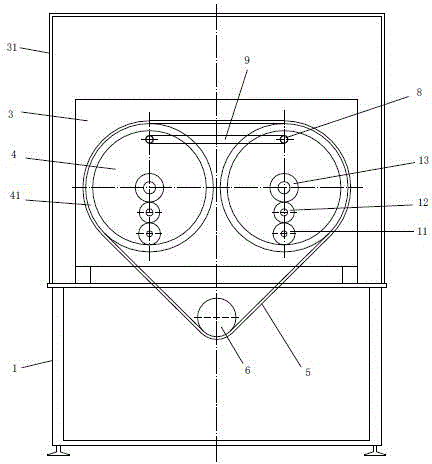

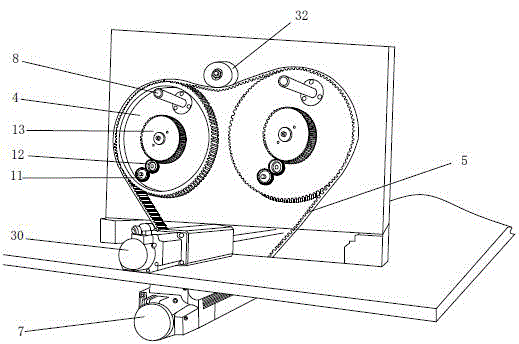

[0064] Such as Figure 1 to Figure 4 As shown, the flying disc type automatic winding machine of the present invention includes a support 1, a table top plate 2 is arranged on the support 1, a machine head seat 3 is fixedly arranged on the table top plate 2, and two rotating flying discs 4 are arranged on the machine head seat 3 , the flying disc 4 is arranged in the flying disc pulley 41; the two flying disc pulleys 41 are connected to the driving wheel 6 through the conveyor belt 5; the driving wheel 6 is driven by the main motor 7 to drive the flying disc 4 to rotate; the flying disc 4 is fixed on the nose by the flying disc bearing 42 On the bearing frame of the seat 3; the outer side of the conveyor belt 5 is provided with a pressing roller 32 for tensioning the conveyor belt 5;

[0065] The flying disc 4 is fixedly provided with a hollow tubular type fly-fork rod 8 for the lead-in wire; the flying-fork rod 8 is fixed on the off-center position of the flying disc end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com