Wear-resistant, corrosion-resistant high-entropy amorphous alloy powder and its coating, coating preparation method and application

A technology of amorphous coating and amorphous alloy, applied in the field of alloys, can solve the problems of limited types of high-entropy amorphous coatings, difficulty in ensuring coatings, and low amorphous content, so as to improve coating adhesion and coating Quality, improved corrosion resistance, high toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

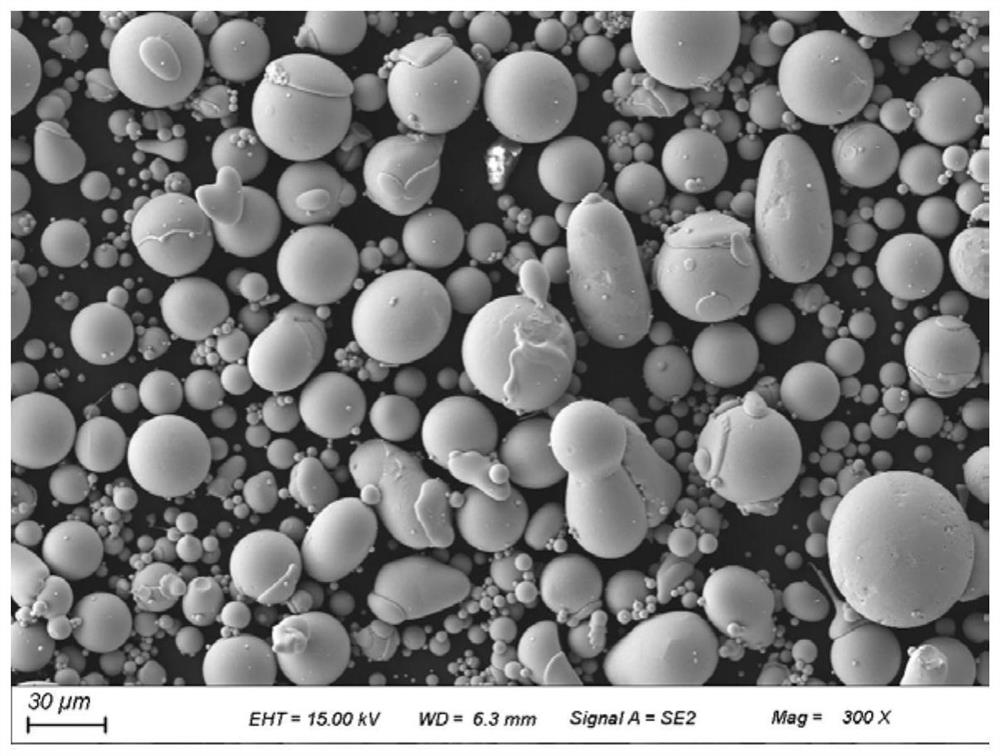

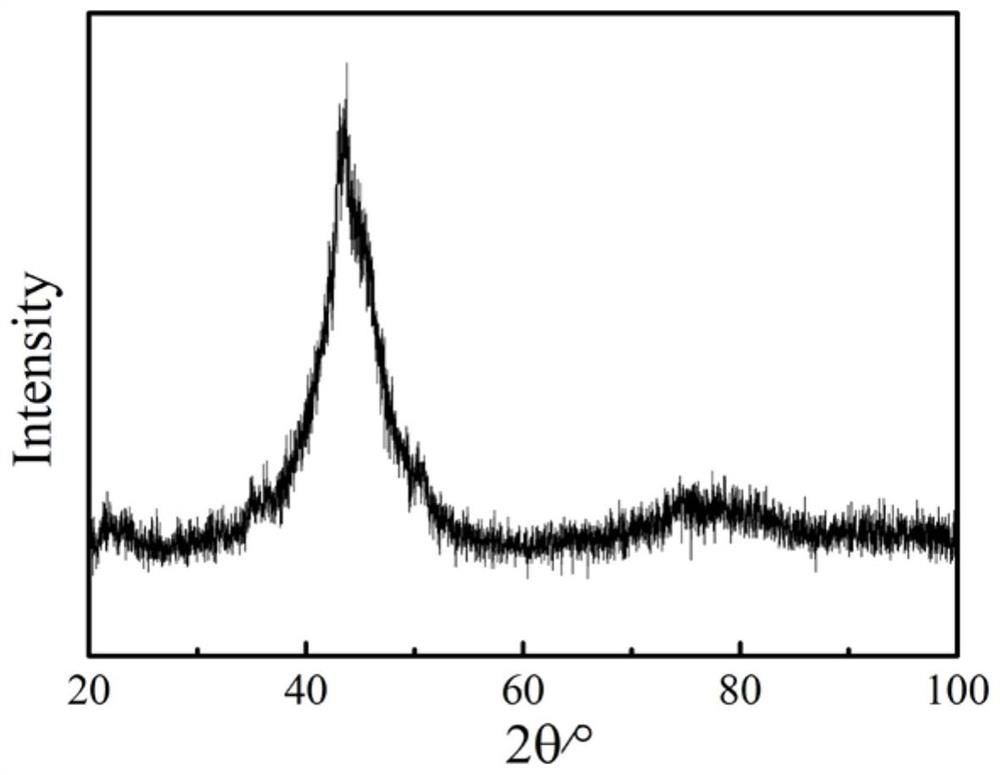

Embodiment 1

[0038] Wear-resistant, corrosion-resistant high-entropy amorphous alloy powder, according to the powder atomic percentage: Co 26%, Ni 26%, Cr 18%, Mo8%, Nb 2%, B 14%, Si 6%, weighing ingredients. The laminar flow ultrasonic argon atomization method is a tool that puts the above-mentioned powder into the crucible furnace, vacuumizes it and pours it into high-purity argon for melting, and inputs the liquid droplets to be atomized after melting to the ultrasonic transducer The surface of the head is atomized into small droplets under ultrasonic vibration. The high-entropy amorphous alloy powder is prepared by laminar flow ultrasonic argon atomization method, and the alloy powder with a particle size of 150-800 mesh is obtained, and three kinds of 150-300 mesh, 300-400 mesh, and 400-800 mesh are sieved by a powder sieving machine. particle size grade powder.

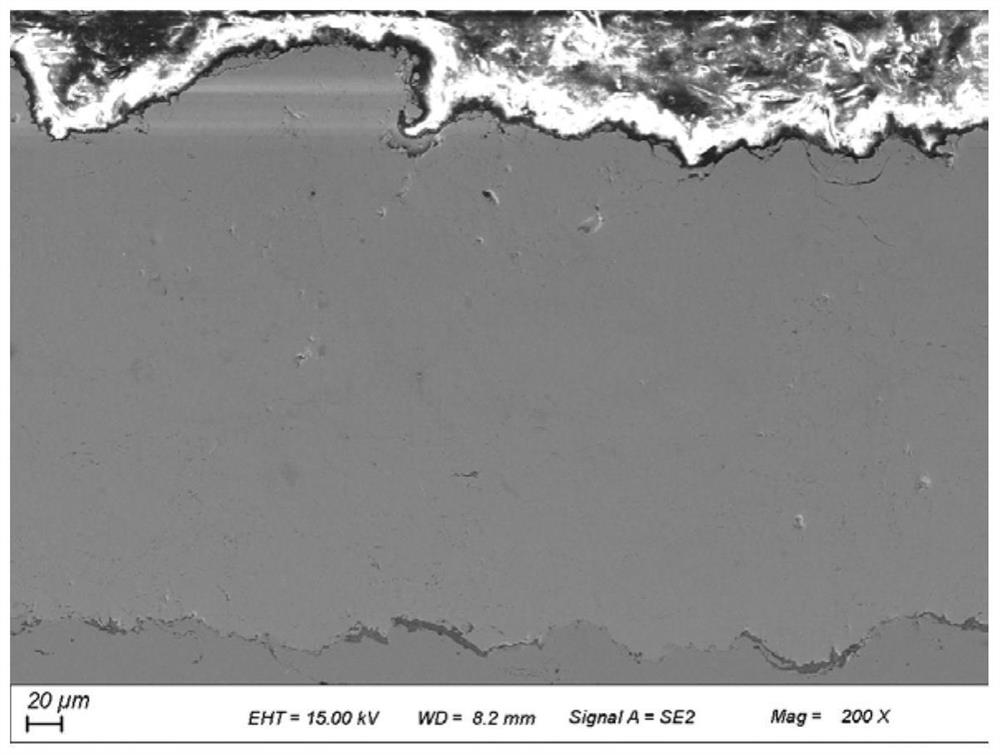

[0039] A coating prepared by using the above-mentioned wear-resistant and corrosion-resistant high-entropy amorphous allo...

Embodiment 2

[0049] Wear-resistant, corrosion-resistant high-entropy amorphous alloy powder, according to the powder atomic percentage: Co 26%, Ni 26%, Cr 17%, Mo7%, Nb 4%, B 14%, Si 6%, weighing ingredients. The laminar flow ultrasonic argon atomization method is to put the prepared powder into the crucible furnace, vacuumize it and pour it into high-purity argon for melting, and input the melted liquid droplets to be atomized into the tool head of the ultrasonic transducer The surface is atomized into small droplets under ultrasonic vibration. The high-entropy amorphous alloy powder is prepared by laminar flow ultrasonic argon atomization method, and the alloy powder with a particle size of 150-800 mesh is obtained, and three kinds of 150-300 mesh, 300-400 mesh, and 400-800 mesh are sieved by a powder sieving machine. particle size grade powder.

[0050] The preparation method of the coating of high entropy amorphous alloy powder, comprises the following steps,

[0051] S01, pre-treatm...

Embodiment 3

[0056] Wear-resistant, corrosion-resistant high-entropy amorphous alloy powder, according to the powder atomic percentage: Co 26%, Ni 26%, Cr 17%, Mo7%, Nb 4%, B 14%, Si 6%, weighing ingredients. The laminar flow ultrasonic argon atomization method is to put the prepared powder into the crucible furnace, vacuumize it and pour it into high-purity argon for melting, and input the melted liquid droplets to be atomized into the tool head of the ultrasonic transducer The surface is atomized into small droplets under ultrasonic vibration. The high-entropy amorphous alloy powder is prepared by laminar flow ultrasonic argon atomization method, and the alloy powder with a particle size of 150-800 mesh is obtained, and three kinds of 150-300 mesh, 300-400 mesh, and 400-800 mesh are sieved by a powder sieving machine. particle size grade powder.

[0057] The preparation method of the coating of high entropy amorphous alloy powder, comprises the following steps,

[0058] S01, pre-treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com