Electrode groove detection method and device

A technology of slot detection and pole piece, which is applied in the field of pole piece slotting detection method and device, can solve the problems of tab failure, current collector welding, damage to current collector, etc., and achieve the effect of reasonable depth and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

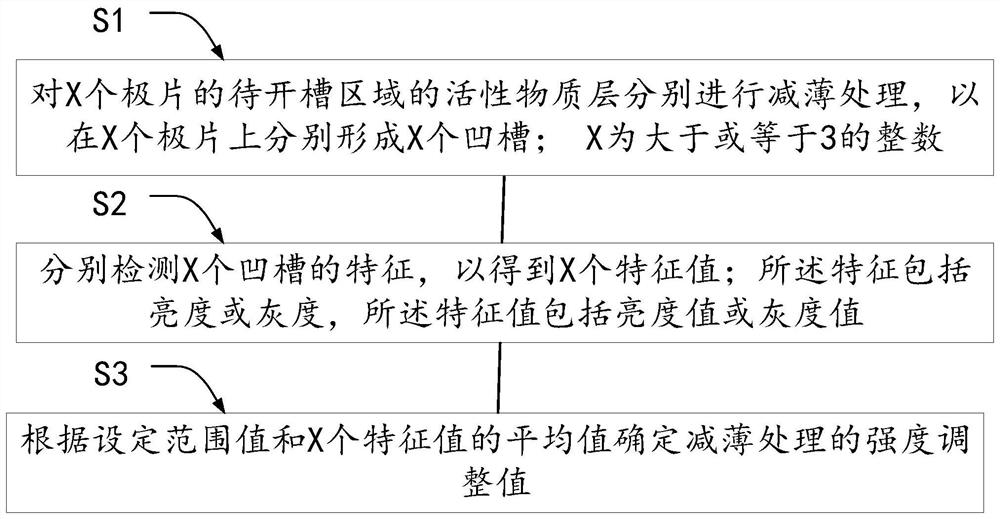

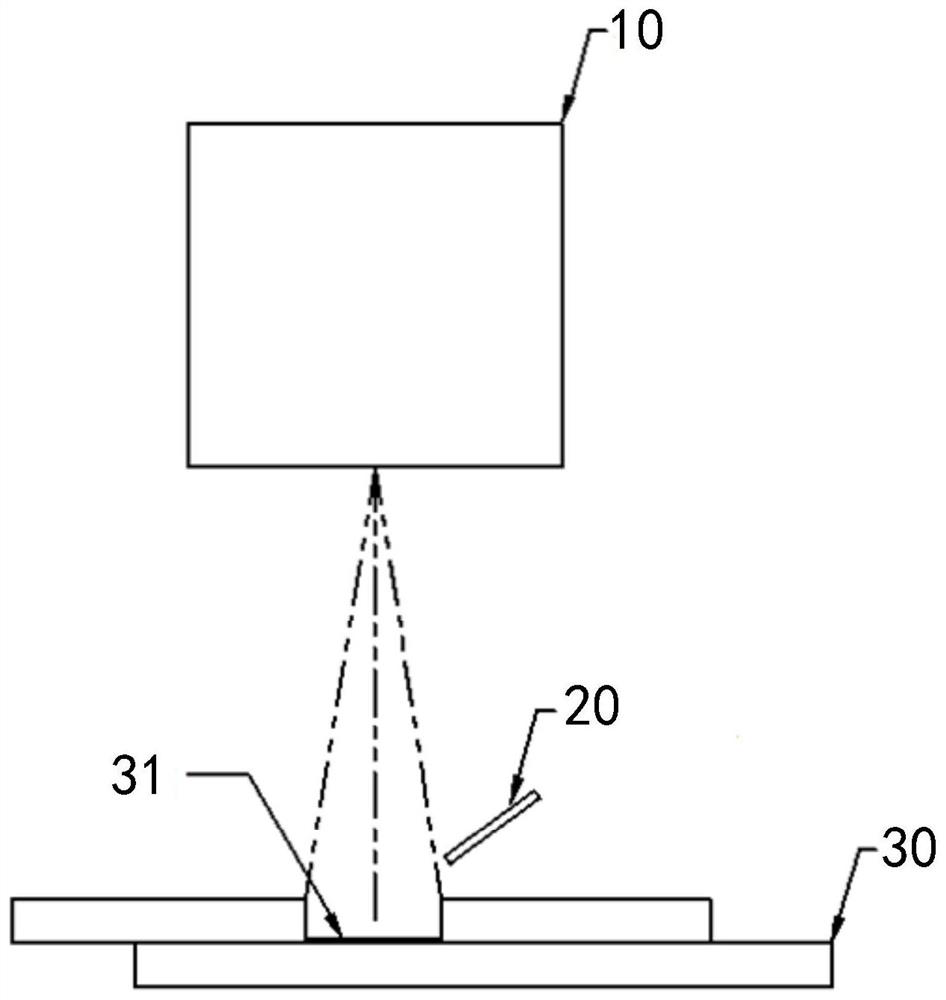

[0021] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0022] The pole piece is briefly described below. As a core component of a lithium-ion battery, the pole piece includes a current collector layer and an active material layer, and the active material layer is arranged on two opposite surfaces of the current collector layer. Generally, tabs need to be welded on the pole piece to lead out the positive and negative poles. Since the tab needs to be welded to the current collector layer, it is necessary to remove the active material layer on the pole piece where the tab needs to be welded. The process of removing the active material layer is also called slotting.

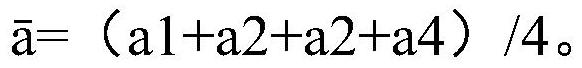

[0023] Generally, during the slotting process, the active material layer will be thinned first with a laser, and after a very thin active material layer is left, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com