Spinning forming device and forming method with bionic drag-reducing surface fairing

A technology of spinning forming and fairing, which is applied to household appliances, other household appliances, hollow objects, etc., can solve the problem that the line shape is not easy to guarantee, and achieve the effect of simple and efficient processing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

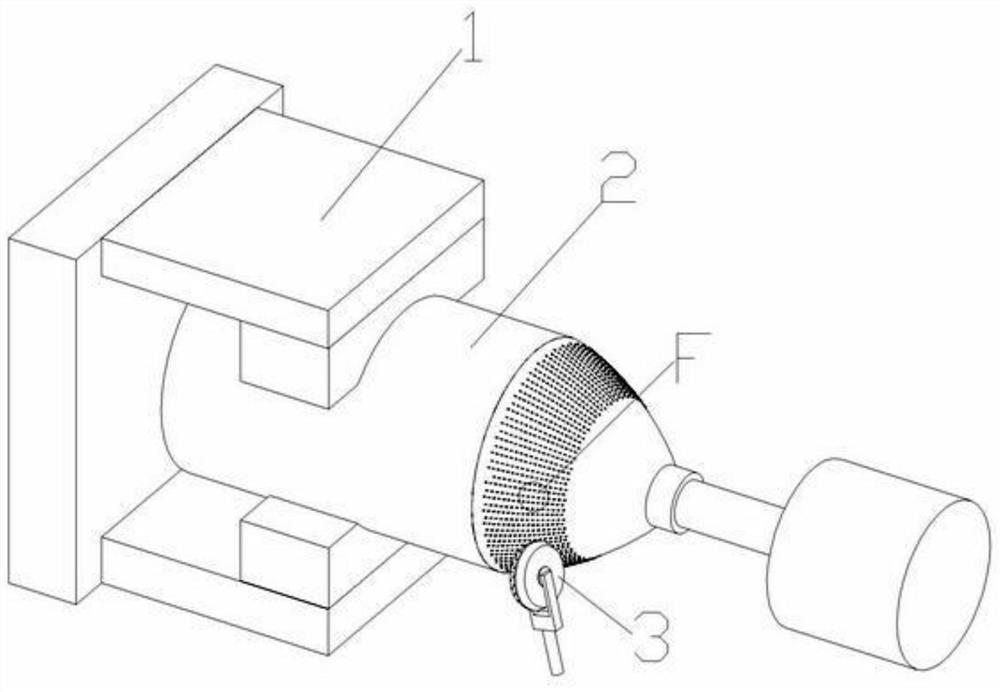

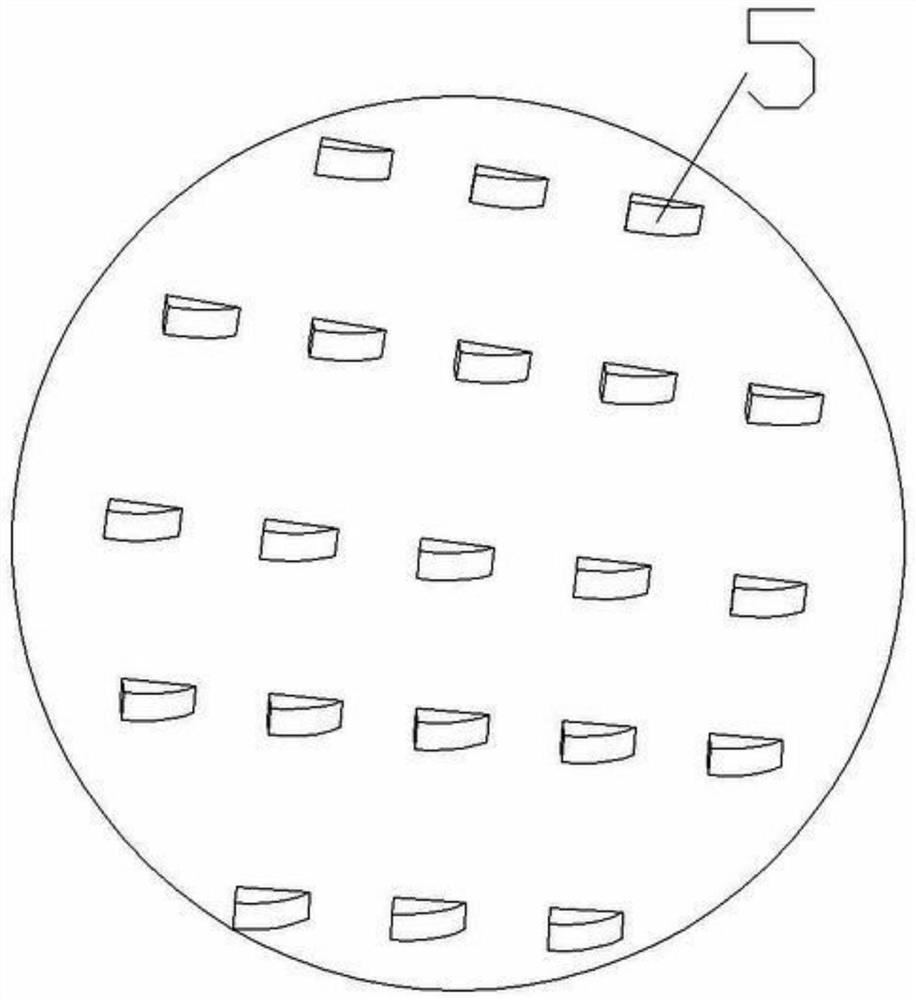

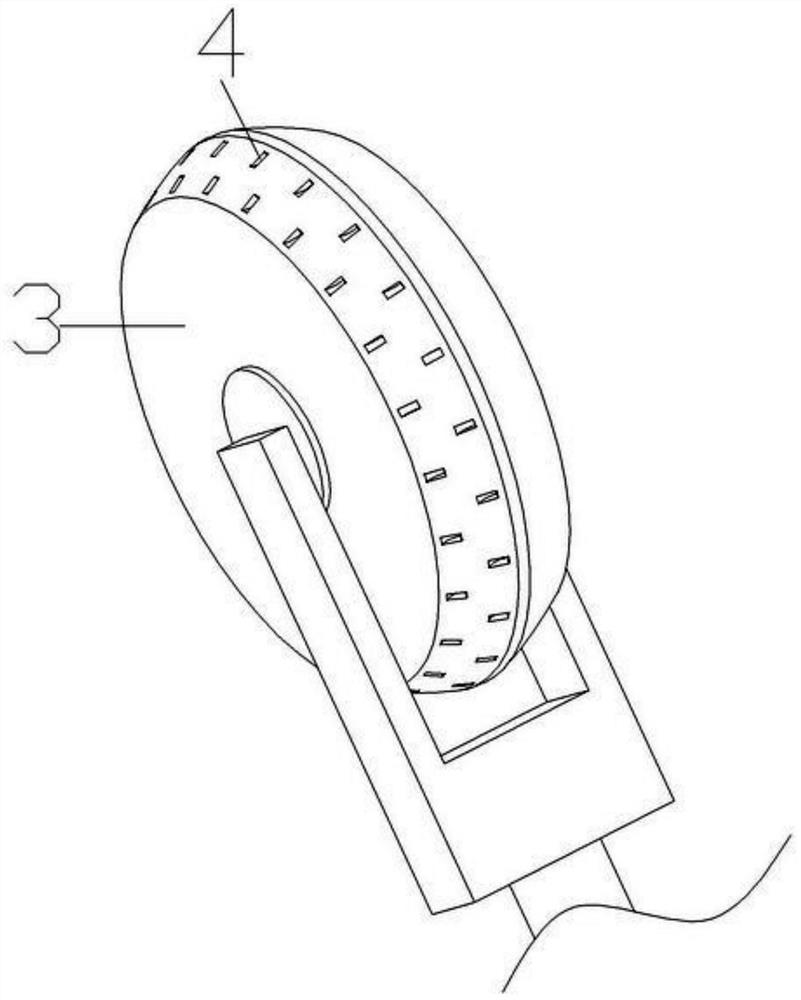

[0019] Referring to the accompanying drawings, the spinning forming device with a bionic drag-reducing surface fairing includes a clamp 1, a blank 2 and a roller 3, the blank 2 is a cylindrical structure, and the blank 2 is clamped It is fixed on the jig 1 and the formed part of the blank 2 is exposed outside the jig 1. The jig 1 rotates in the circumferential direction with the main shaft. The roller 3 is disc-shaped. The extended filling roller groove 4, the roller 3 is connected with the external power device, and the external power device can control the roller 3 to make the roller 3 fully squeeze the blank 2 at a certain feed speed and axial feed amount The diameter is continuously reduced and regularly arranged shark-fin-like streamlined protrusions 5 are left on the outer surface of the formed part of the blank 2 .

[0020] Furthermore, the outer arc surface C of the filling roller groove 4 is a part of a circle with a diameter of 5.8 mm, the distance B between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com