Chemical raw material storage tank imitating inner floating roof storage tank

A technology for internal floating roof storage tanks and chemical raw materials, applied in the field of storage tanks, can solve the problems of high requirements, difficult maintenance, and high punching costs, and achieve the effects of reducing settings, reducing losses, and reducing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

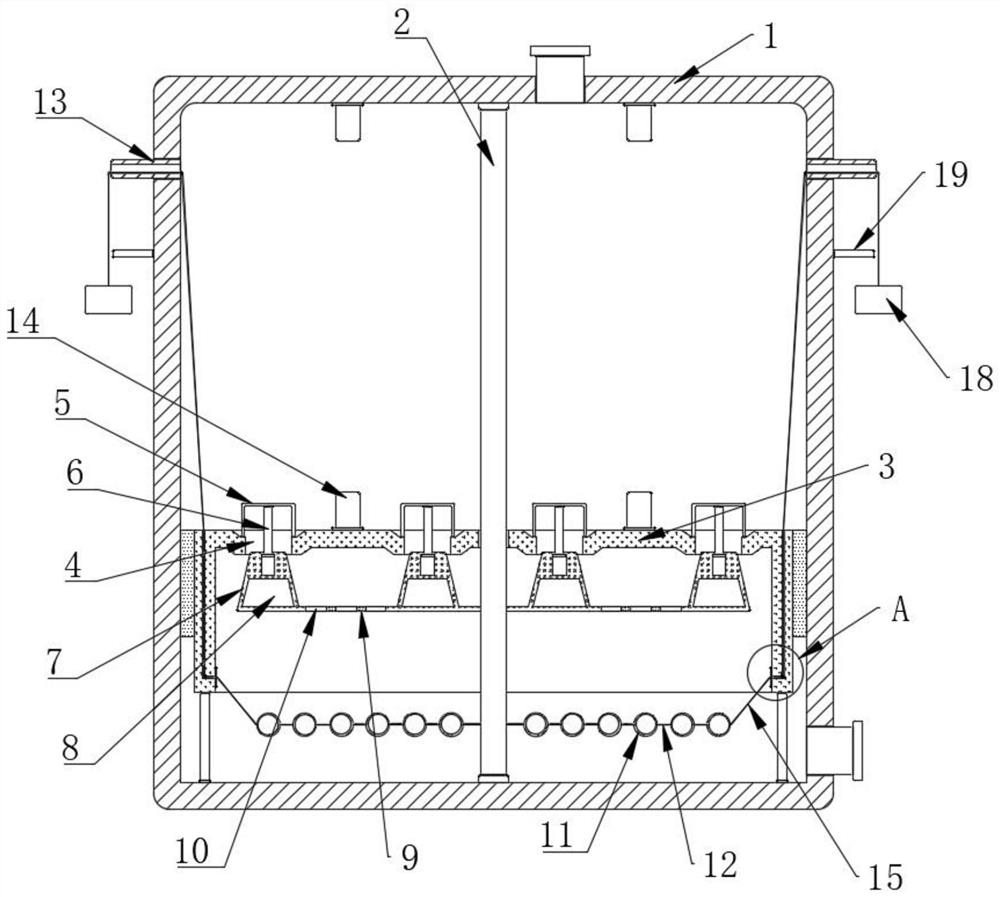

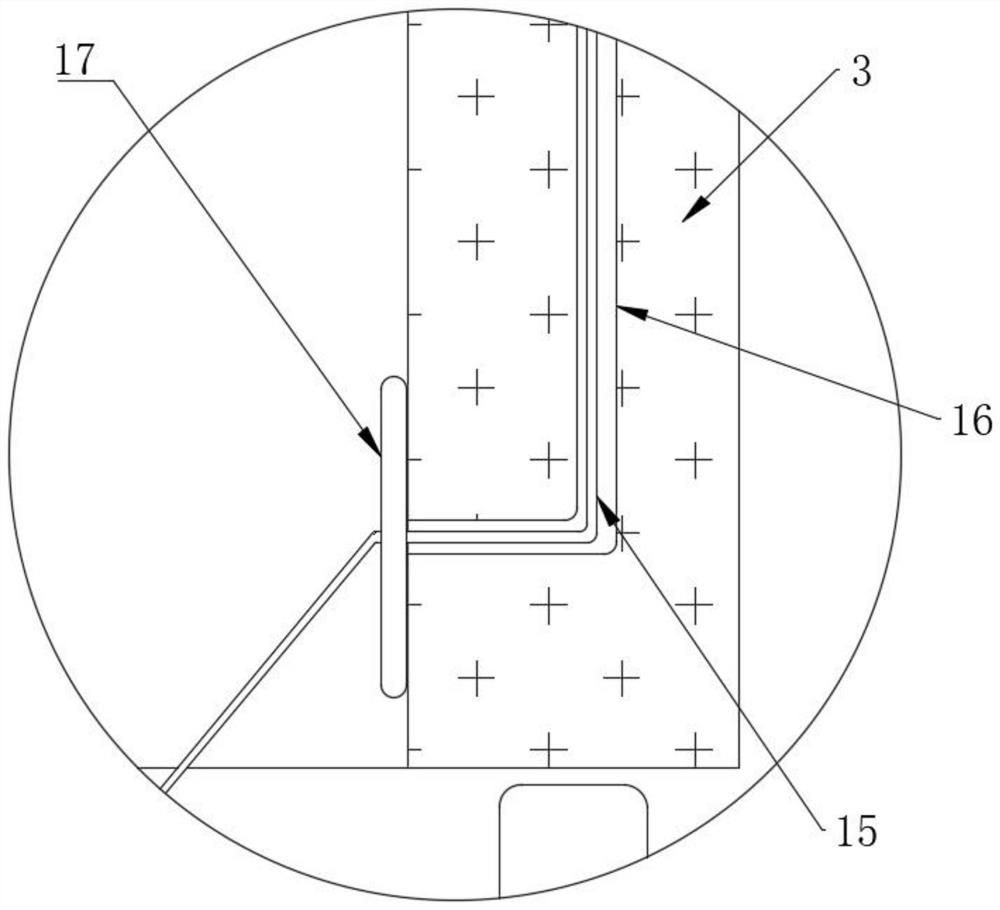

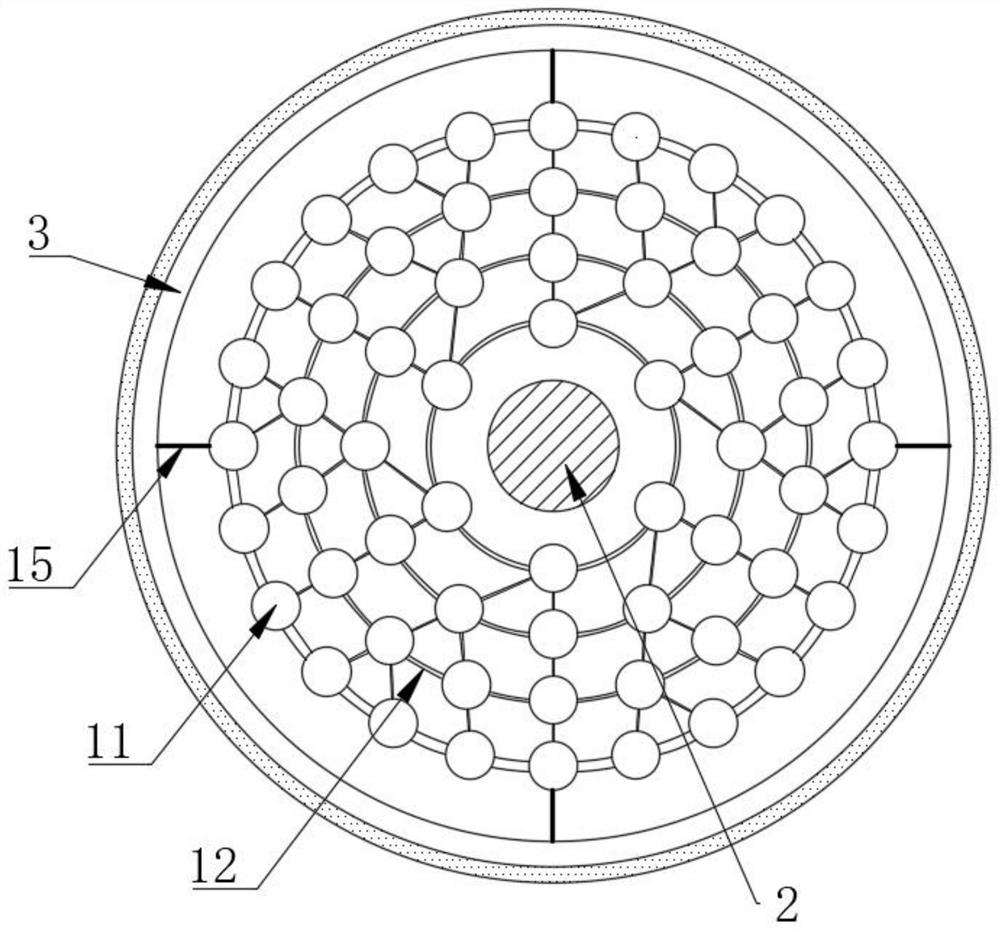

[0041] see Figure 1-6 , a chemical raw material storage tank imitating an internal floating roof storage tank, comprising a storage tank 1, a guide rod 2 fixedly connected to the inner wall of the middle part of the storage tank 1, a floating cover 3 slidingly connected to the outer wall of the guide rod 2, and a floating cover 3 A sealing layer is fixedly connected to the outer wall of the storage tank 1, and the sealing layer is attached to the inner wall of the storage tank 1. A plurality of feeding tanks 4 are provided between the upper and lower sides of the top of the floating cover 3, and the position of the floating cover 3 close to the feeding tank 4 is set as Concave shape, the material on the upper side of the floating cover 3 can better fall into the lower side of the floating cover 3 through the lower chute 4 through the adjustment of the floating cover 3, and the top surface of the floating cover 3 close to the lower trough 4 is fixedly connected with a support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com