Construction Method of In-Situ Suspension Protection for Long-distance Span Foundation Pit Box Culvert

A construction method and long-distance technology, which is applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of prolonging the construction period of foundation pits, using various large-scale mechanical equipment and manpower for box culverts, and spending a certain amount of time, so as to save manpower and Material resources, construction time saving, and the effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

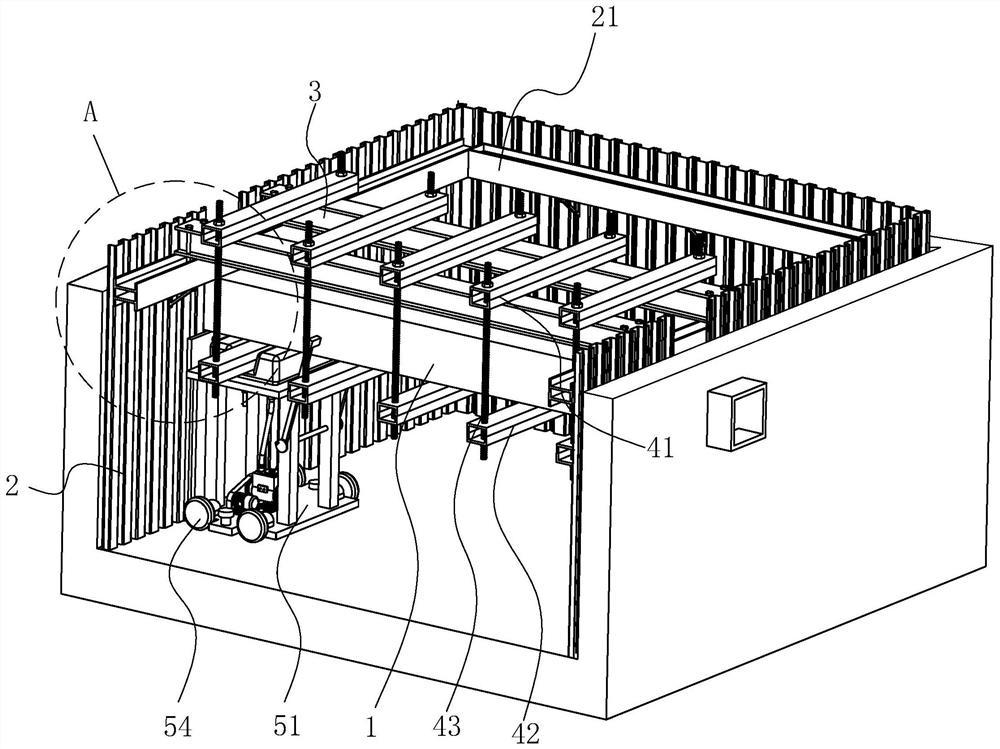

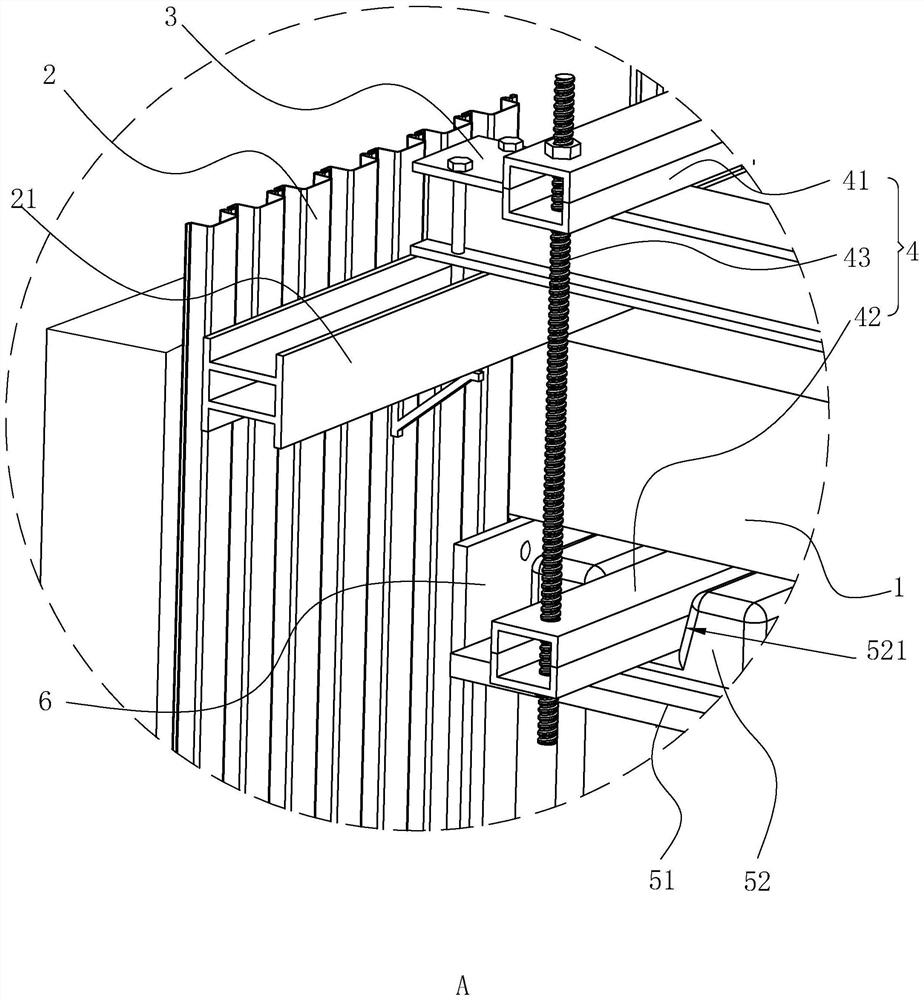

[0042] The following is attached Figure 1-4 The application is described in further detail.

[0043] The embodiment of the present application discloses a construction method for in-situ suspension protection of long-distance box culvert spanning foundation pits, referring to figure 1 and figure 2 , including the following steps:

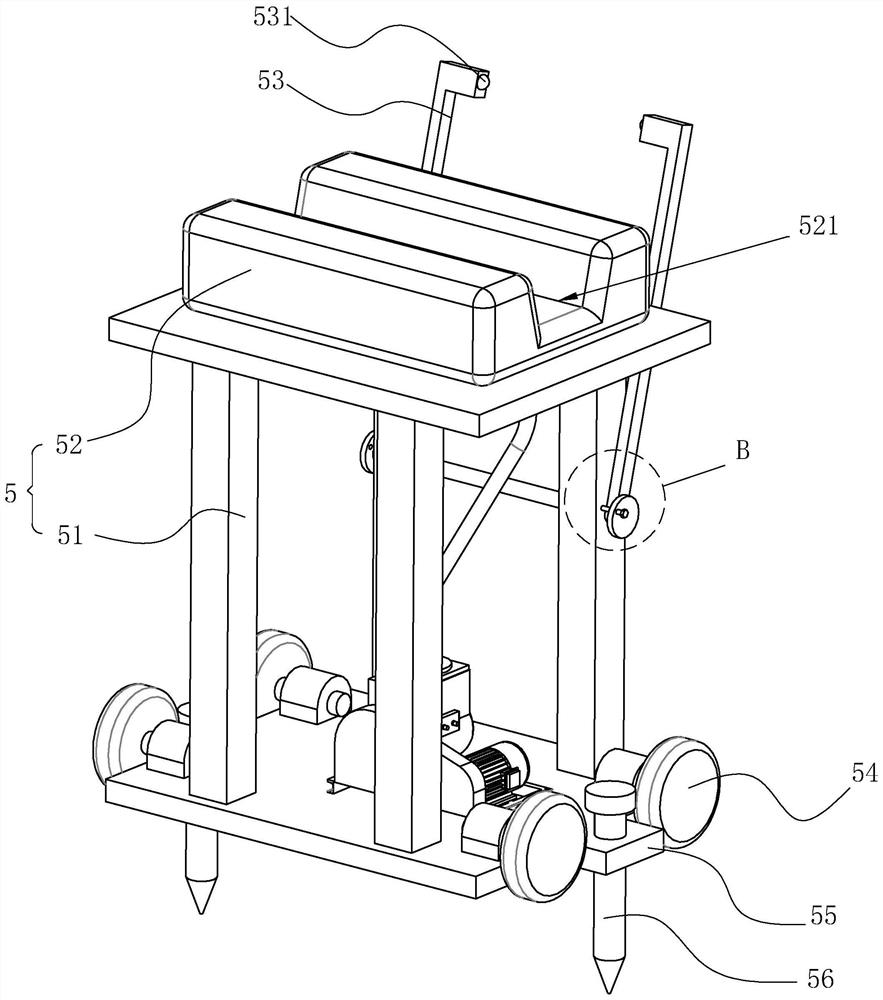

[0044] S1: prefabricated load-bearing rod 3, several groups of suspension components 4 and top support components 5, suspension component 4 includes upper compression rod 41, lower compression rod 42 and two groups for connecting upper compression rod 41 and lower compression rod 42 To pull screw rod 43; In the present embodiment, bearing bar 3 quantity is two groups, and bearing bar 3 is steel double channel steel, helps to keep bearing bar 3 overall strength; Upper pressure bar 41 and lower The pressure rod 42 is aluminum alloy double channel steel;

[0045] S2: Excavate the area to be constructed in the foundation pit until the top of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com