Offshore wind power multi-pile foundation integral berthing anti-collision structure and construction method

A technology for offshore wind power and pile foundations, applied in foundation structure engineering, sheet pile walls, climate change adaptation, etc., can solve the problems of increased difficulty and cost, unreliable construction quality, heavy workload, etc., and occupy the time of marine machinery and equipment Short, less construction process, high overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

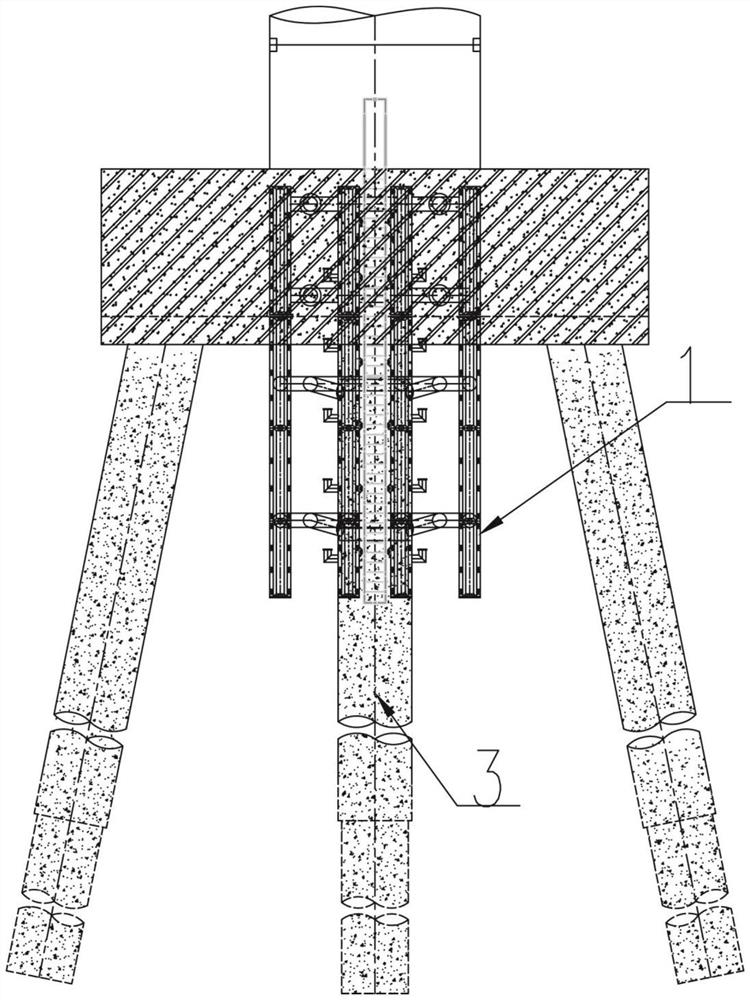

[0034] The overall anti-collision structure for berthing a multi-pile foundation of offshore wind power includes a berthing anti-collision member 1 , a grouted fixing member 2 and an inclined pile 3 .

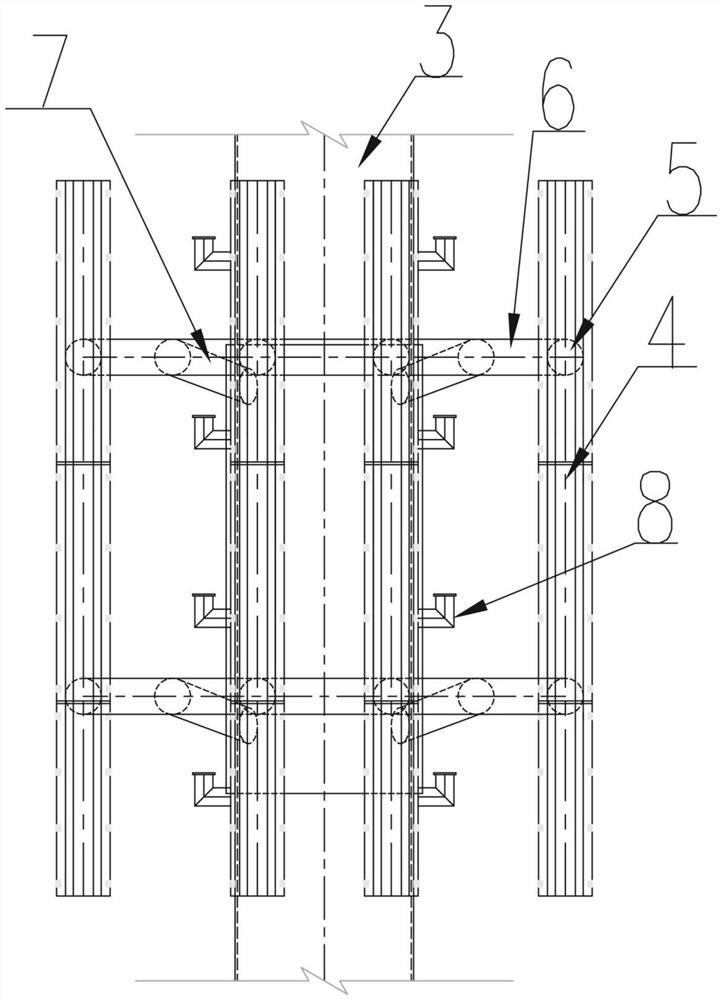

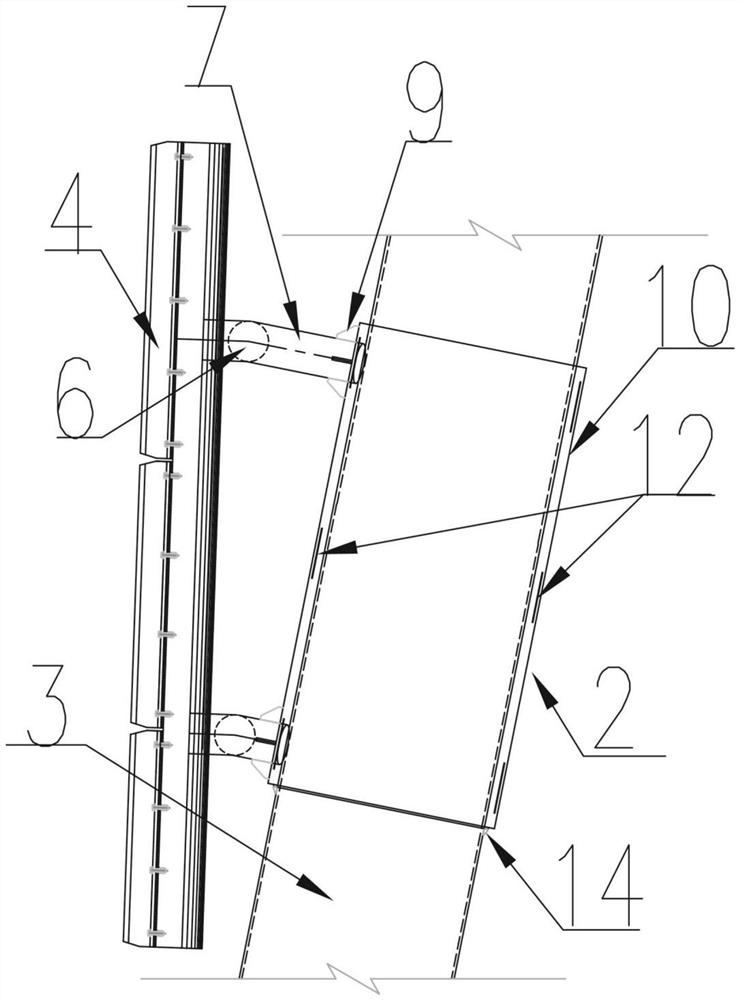

[0035] The berthing anti-collision member 1 is mainly used for berthing ships, and can play a certain buffering role to prevent the berthing hull from directly hitting the pile. It mainly includes vertical rubber fenders 4, berthing struts 5, berthing cross struts 6, berthing diagonal struts 7, mooring pipes 8, and stiffening plates 9 at the welds between the struts and the steel casing. One side of the diagonal strut 7 is connected with the grouting fixing member 2, and the other side is connected with the strut 5, and the strut 5 and the diagonal strut 7 are fixed by the cross strut 6. There are two layers of berthing struts 7, which can effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com