High-strength and high-corrosion-resistant aluminum alloy for heat exchanger pipe, and heat exchanger pipe manufactured therefrom

A technology for heat exchangers and aluminum alloys, which is applied in heat exchange equipment, lighting and heating equipment, metal material coating technology, etc., can solve the problems of insufficient extrudability of aluminum alloys and reduced productivity, and achieve excellent results. The effect of reducing the manufacturing unit price and maintaining physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] 1. Manufacturing example

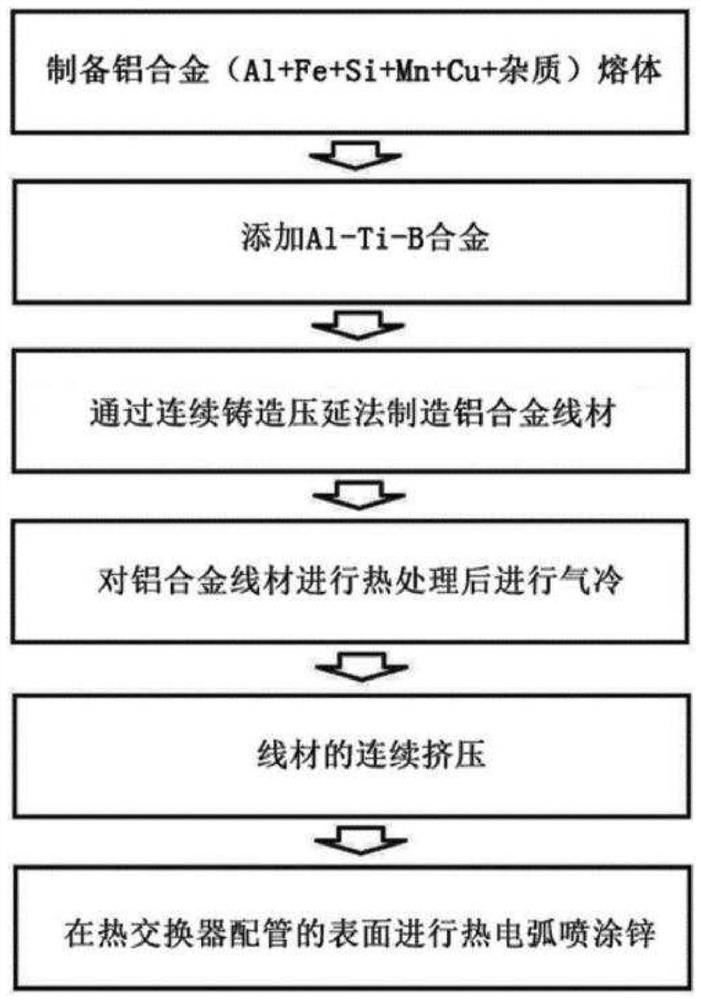

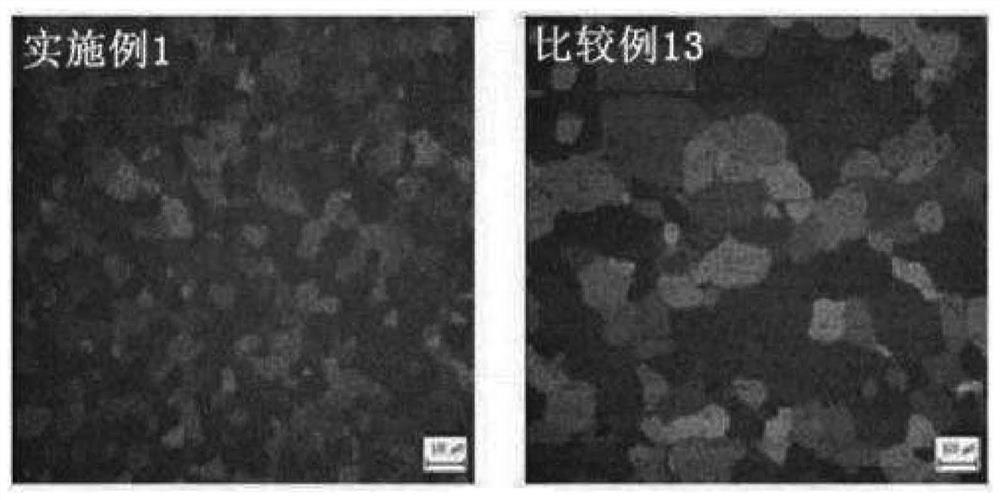

[0083] Through the continuous casting and calendering method, aluminum wires are manufactured separately from various aluminum alloys (750-900° C.), and wound on bobbins in the form of coils, and the various aluminum alloys include the contents shown in Table 1 below. Alloying elements, the balance is composed of aluminum and other unavoidable impurities. Among them, regarding the addition of titanium (Ti) as an alloying element, in Examples 1 to 7 and Comparative Examples 1 to 6, 8 to 12, Al-Ti-B alloy was added to the aluminum alloy melt before continuous casting and rolling In contrast, in Comparative Example 13, Ti and other alloying elements were added at the same time.

[0084] In addition, in order to homogenize the various aluminum wires, after heat treatment in the order of holding at 450 to 650° C. for 10 to 25 hours and then performing air cooling, a fine structure as shown in Table 1 below was achieved. characteristic.

[0085] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com