Method for calculating NOx measurement value of denitration inlet under purging condition by system error method

A system error, measurement value technology, applied in the control/regulation system, air quality improvement, non-electric variable control, etc. The effect of bumpless switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

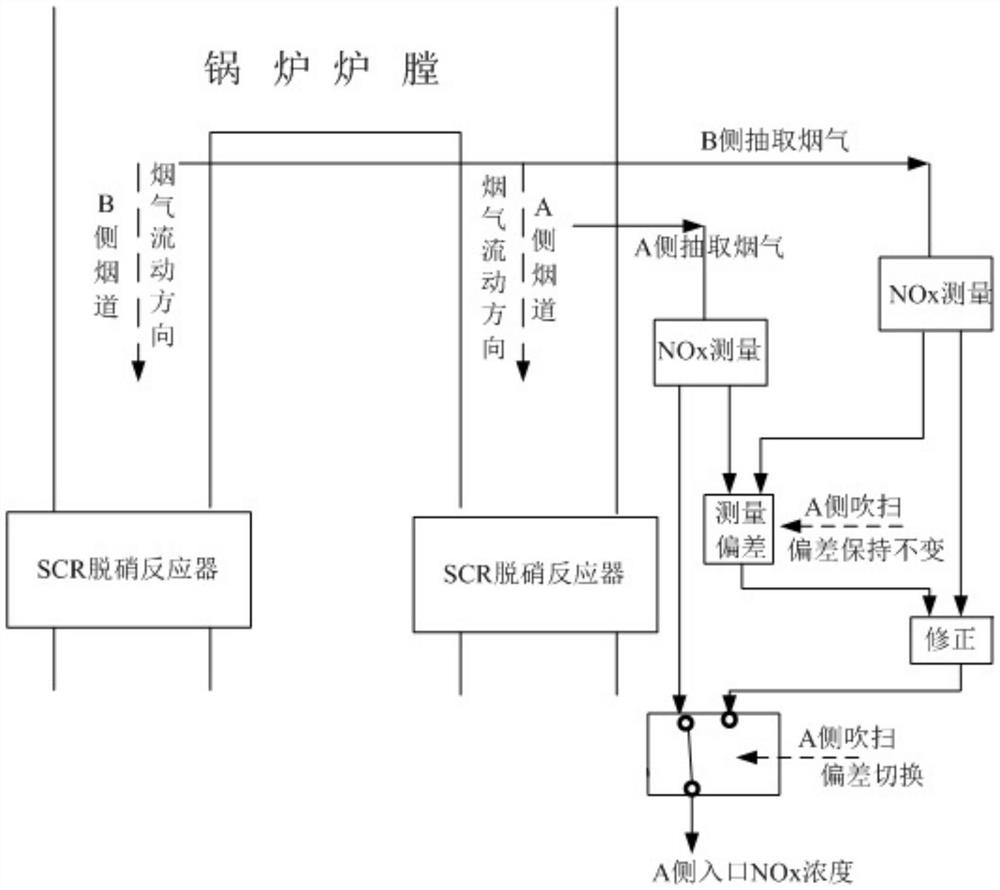

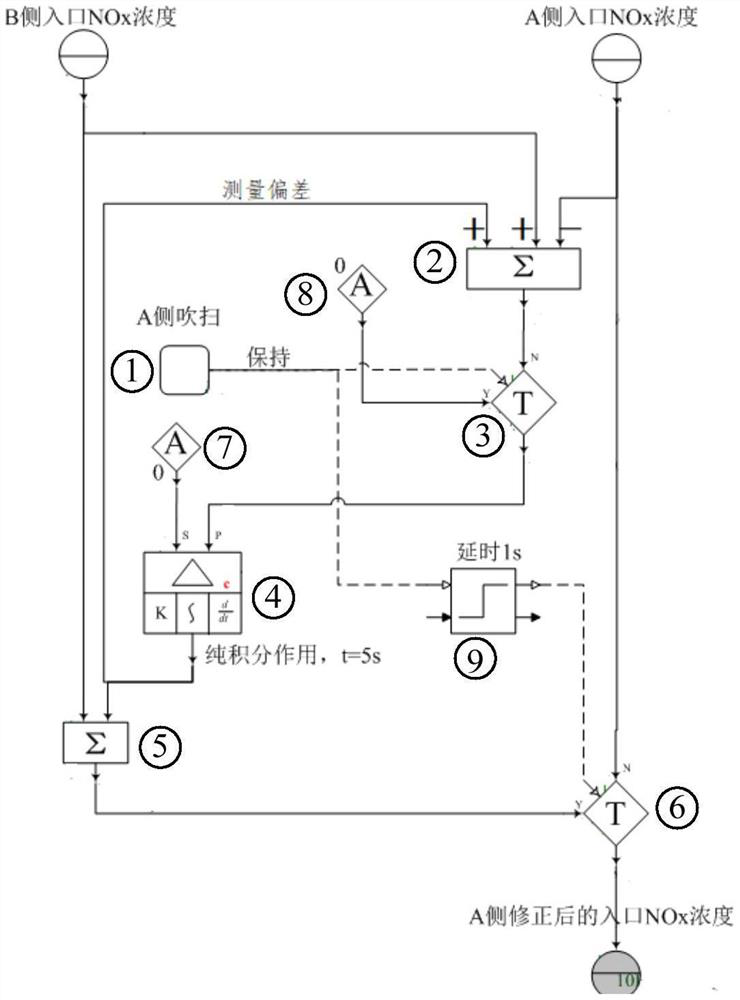

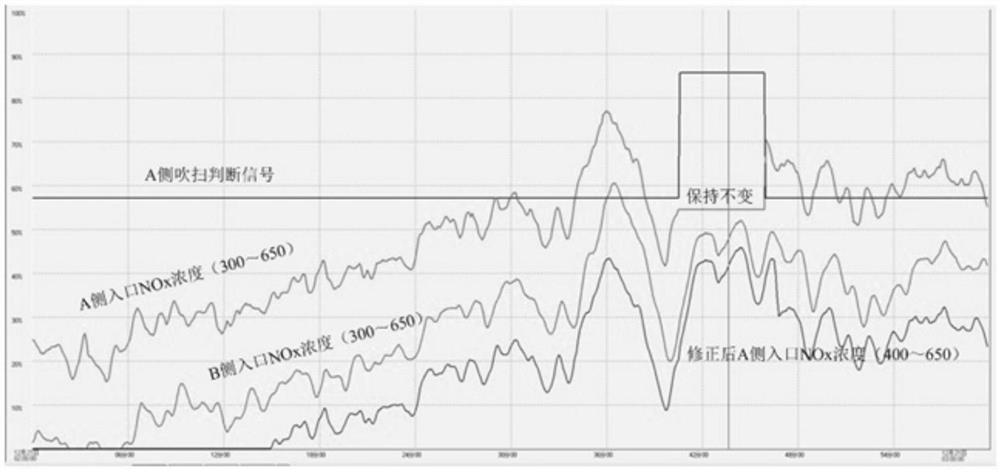

[0028] Such as figure 1 As shown, the flow diagram of the method for calculating the measured value of NOx at the denitrification inlet under the purging condition by the system error method of this embodiment, the method extracts flue gas from the A side and B side flue respectively, and measures it through the NOx concentration measuring instrument , and calculate the systematic error between the measured values of NOx at the denitrification inlets on both sides of the boiler. Since the NOx concentration values at the denitrification inlets on both sides of the boiler are not equal, there is a deviation between the two curves, but in most cases, this deviation is basically Therefore, the error between them can be considered to be a systematic error.

[0029] Under normal working conditions, output the measured value of NOx concentration at the denitrification inlet of side A;

[0030] Under the condition of side A purging, the measured value of NOx concentration at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com