Power semiconductor cooling module for electric vehicle

A technology for power semiconductors and electric vehicles, used in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc., and can solve problems such as reducing the performance of power modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

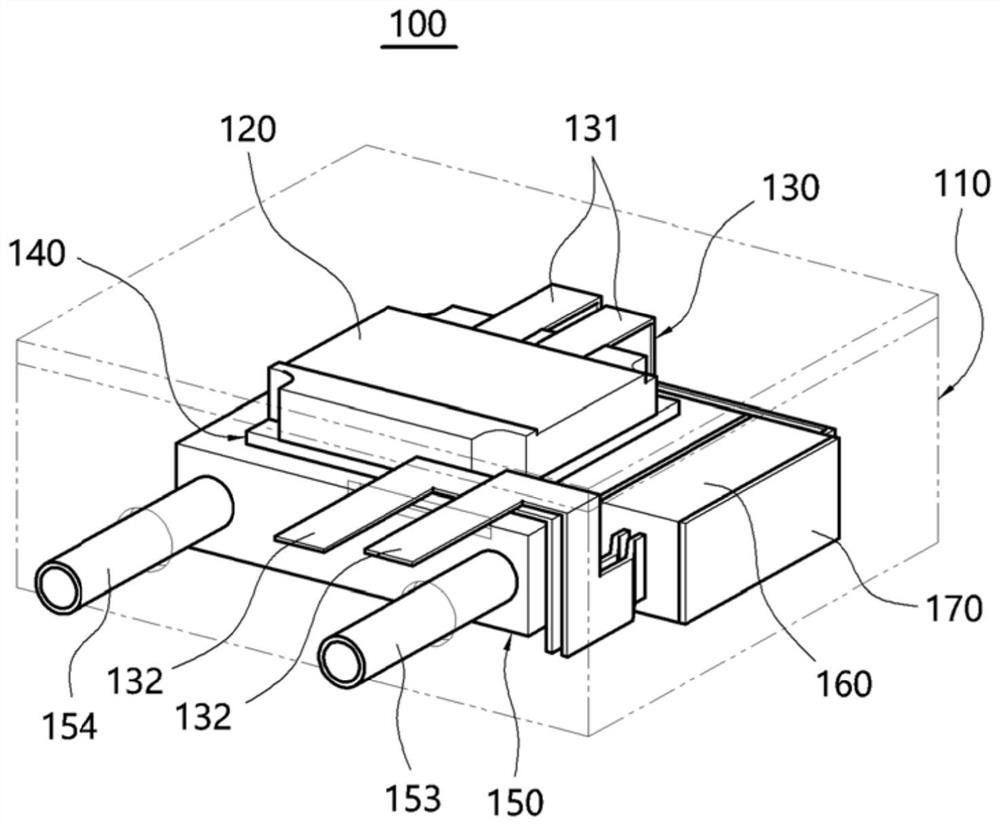

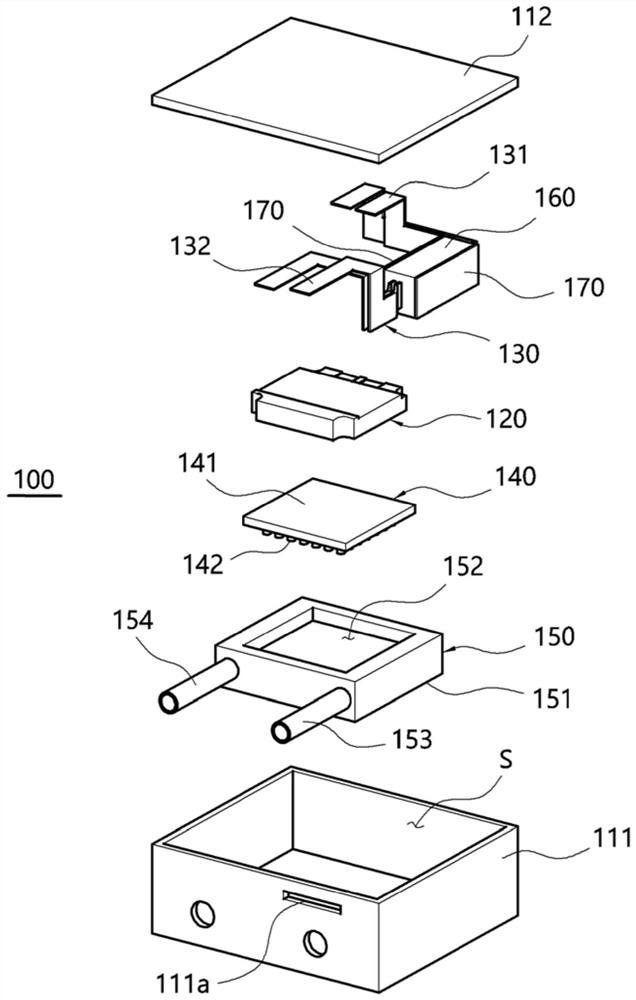

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art to which the present invention pertains can easily implement. The present invention can be realized in various shapes and is not limited to the embodiments described here. For the sake of clarity, parts irrelevant to the description are omitted from the drawings, and the same reference numerals are assigned to the same or similar constituent elements throughout the specification.

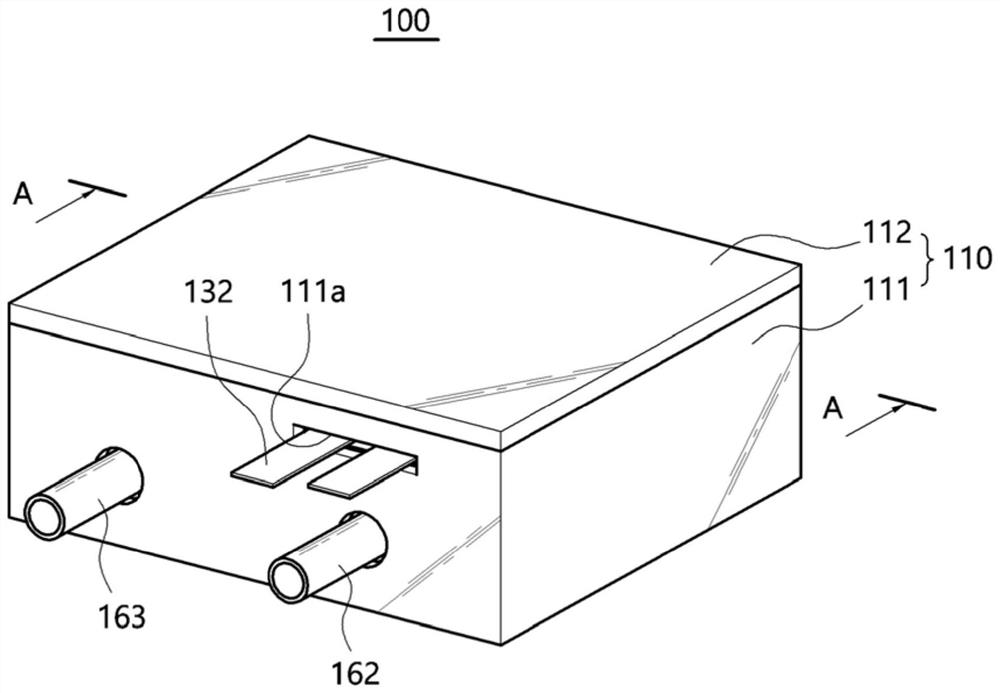

[0028] Such as Figure 1 to Figure 3 As shown, a power semiconductor cooling module 100 for an electric vehicle according to an embodiment of the present invention includes: a housing portion 110 , a power element portion 120 , heat dissipation portions 140 , 150 and a heat backflow preventing component 160 .

[0029] The housing part 110 may be formed in a box shape having an inner space S. As shown in FIG. Accordingly, the housing porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com