Convex hull punching and shaping die

A punching and convex hull technology, which is applied in the field of convex hull punching and shaping molds, can solve problems such as roof collapse, affecting the theoretical wind resistance streamline of the roof, and weak roof rigidity, so as to ensure rigidity, ensure overall, and material thick and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

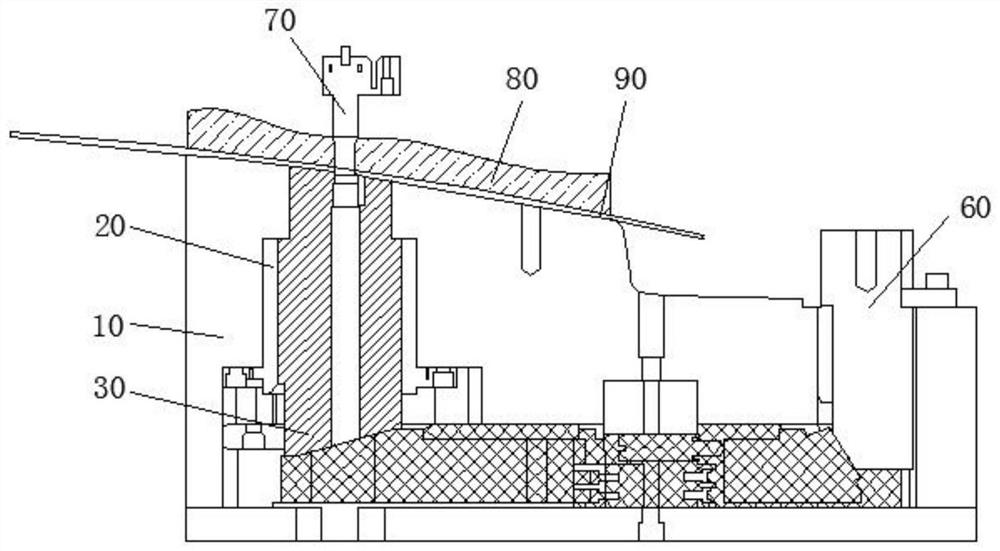

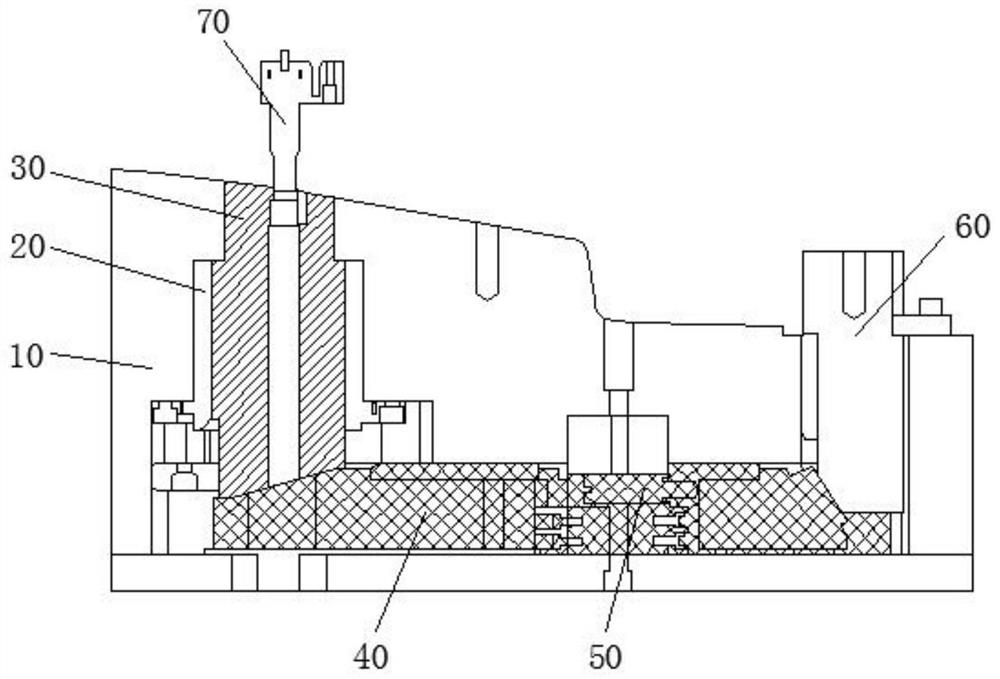

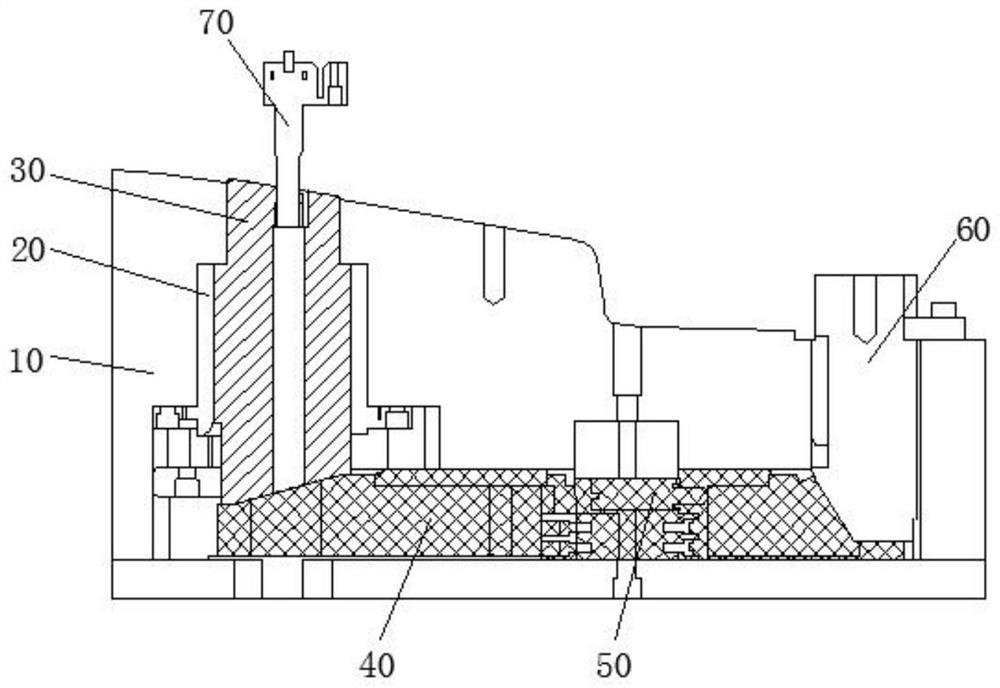

[0019] Such as Figure 1-4 As shown, the convex shell punching and shaping die described in this embodiment includes a mechanism seat 10, a punching shaping insert 30 and a pre-punching punch 70, and a car roof 90 is placed on the top of the mechanism seat 10, and the The top of the mechanism seat 10 is provided with a fixed die 80 clamping to limit the position of the car roof 90, the fixed die 80 is provided with a pre-punching punch 70 for impacting holes, and the described mechanism seat 10 is provided with a punch that can move up and down. Hole shaping insert 30, the punching shaping insert 30 moves up while the pre-punching punch 70 moves down to punch holes.

[0020] One side of the inside of the mechanism base 10 is provided with a guide sleeve 20, and a punching shaping insert 30 is slidably connected to the guide sleeve 20, and the inside of the mechanism base 10 is provided with a tool to drive the punching shaping insert 30 to move up and down. Drive mechanism. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com