Engine compartment heat removal structure

An engine compartment, engine technology, applied in the direction of engine components, engine cooling, machine/engine, etc., to achieve the effect of suppressing the increase of air resistance and promoting heat removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, a manner for carrying out the invention will be described. The description of the preferred embodiments is essentially exemplified, and the present invention is not intended to be limited, and the applicable objects of the present invention thereof.

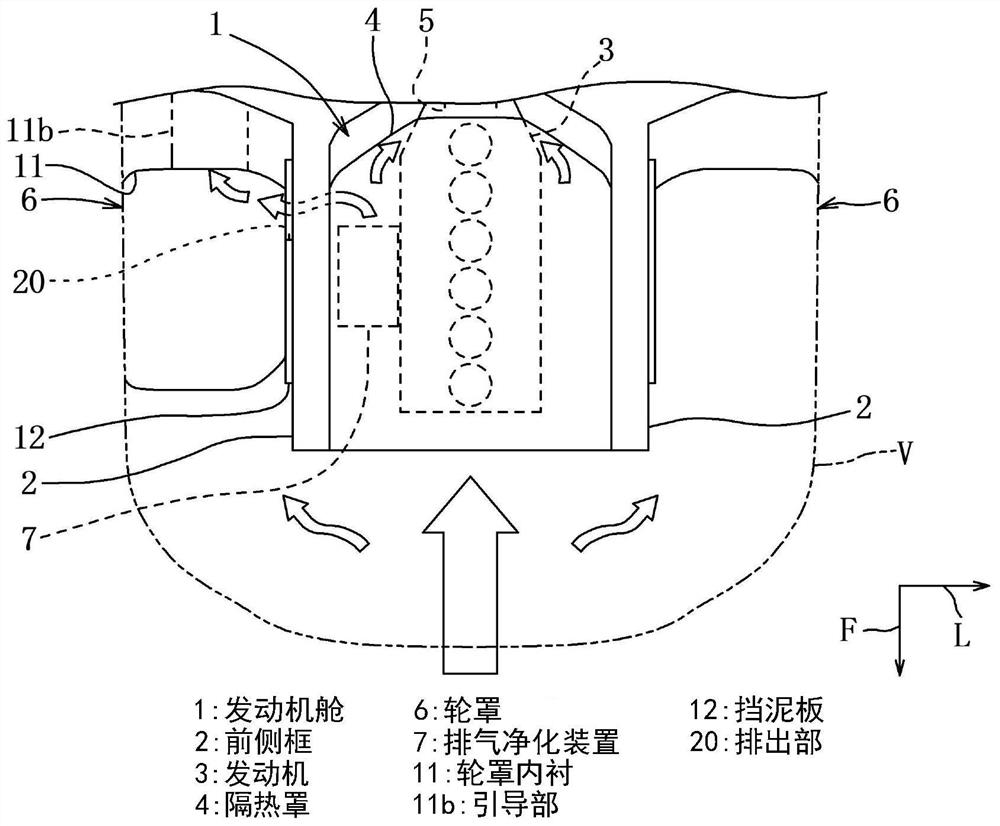

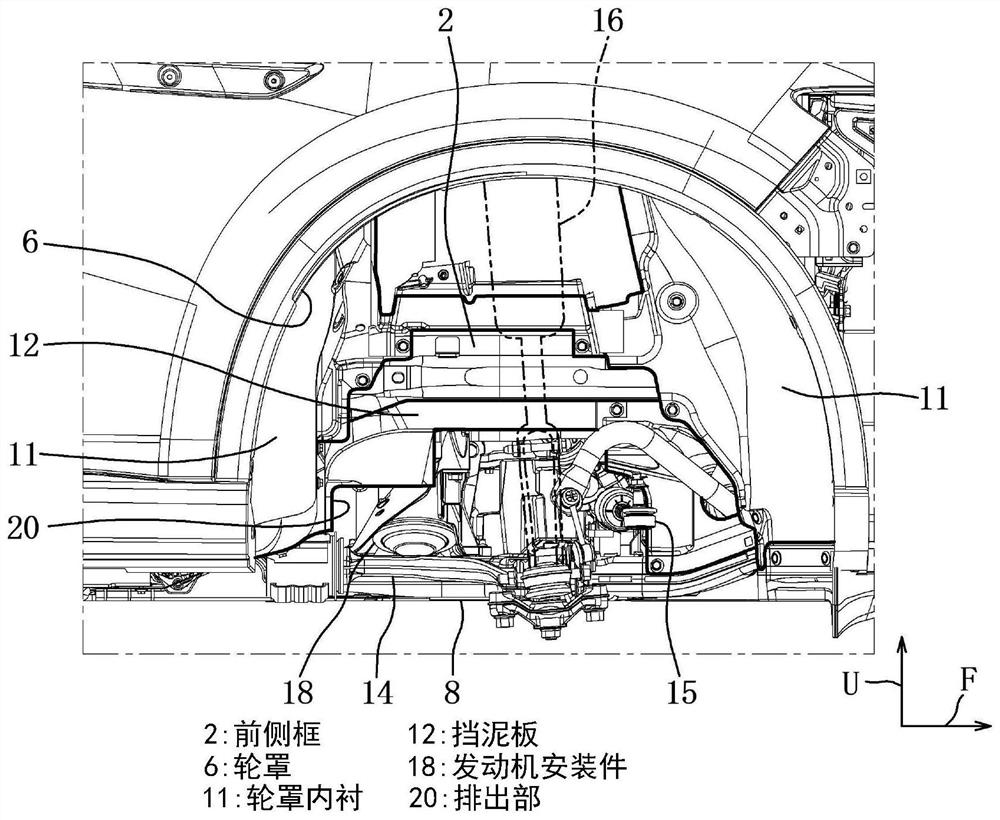

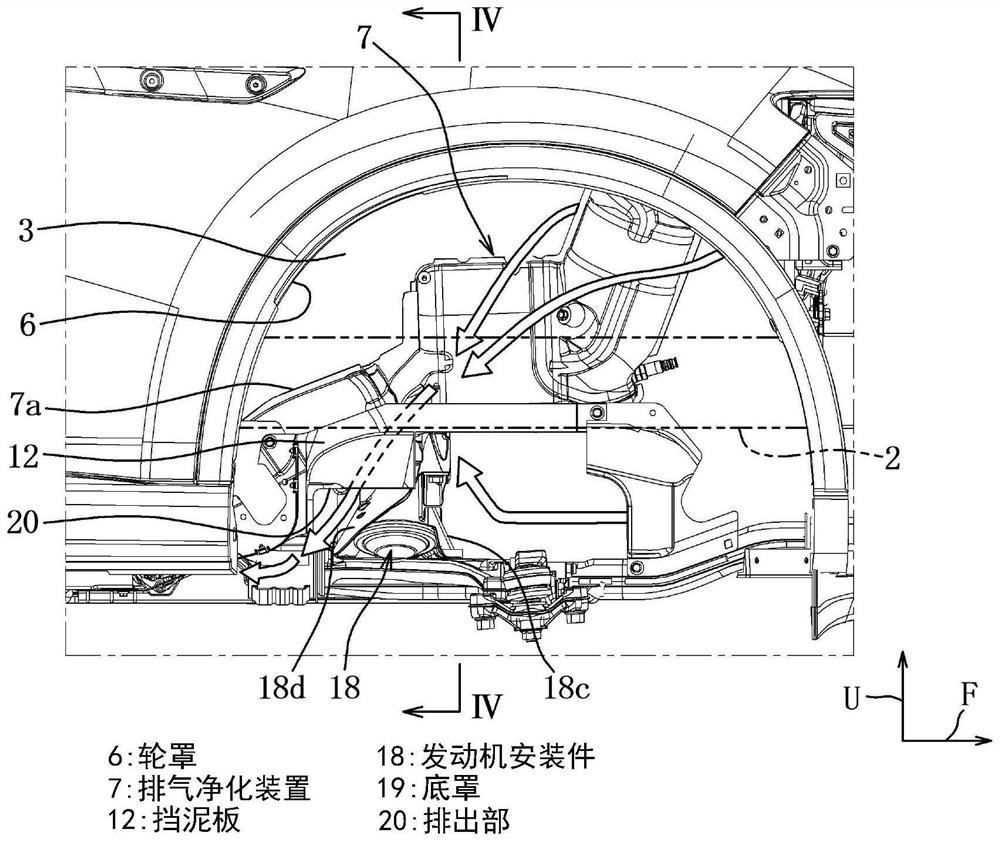

[0057] like figure 1 As shown, an engine compartment 1 is provided at the front side portion of the vehicle V. Hereinafter, the arrow f, the arrow L, the arrow U indicate the front, left, and above of the vehicle. In the engine compartment 1, a multi-cylinder engine 3 (so-called longitudinal engine) arranged in the front-rear direction is housed between a pair of front side frames 2 extending in the front-rear direction of the vehicle V. The engine 3 covers the upper surface, the rear portion, the left side portion, and the portion of the upper surface portion can be opened and closed by the engine cover (hereinafter referred to as the heat shield 4).

[0058] The engine compartment 1 is divided in the vehicle wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com