Stator for electric machine of vehicle, electric machine of vehicle and vehicle

A technology for stators and vehicles, applied in electromechanical devices, electrical components, electrical components, etc., can solve problems such as weakening the mechanical stability of winding ends, and achieve the effects of reducing heat load, good heat removal, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

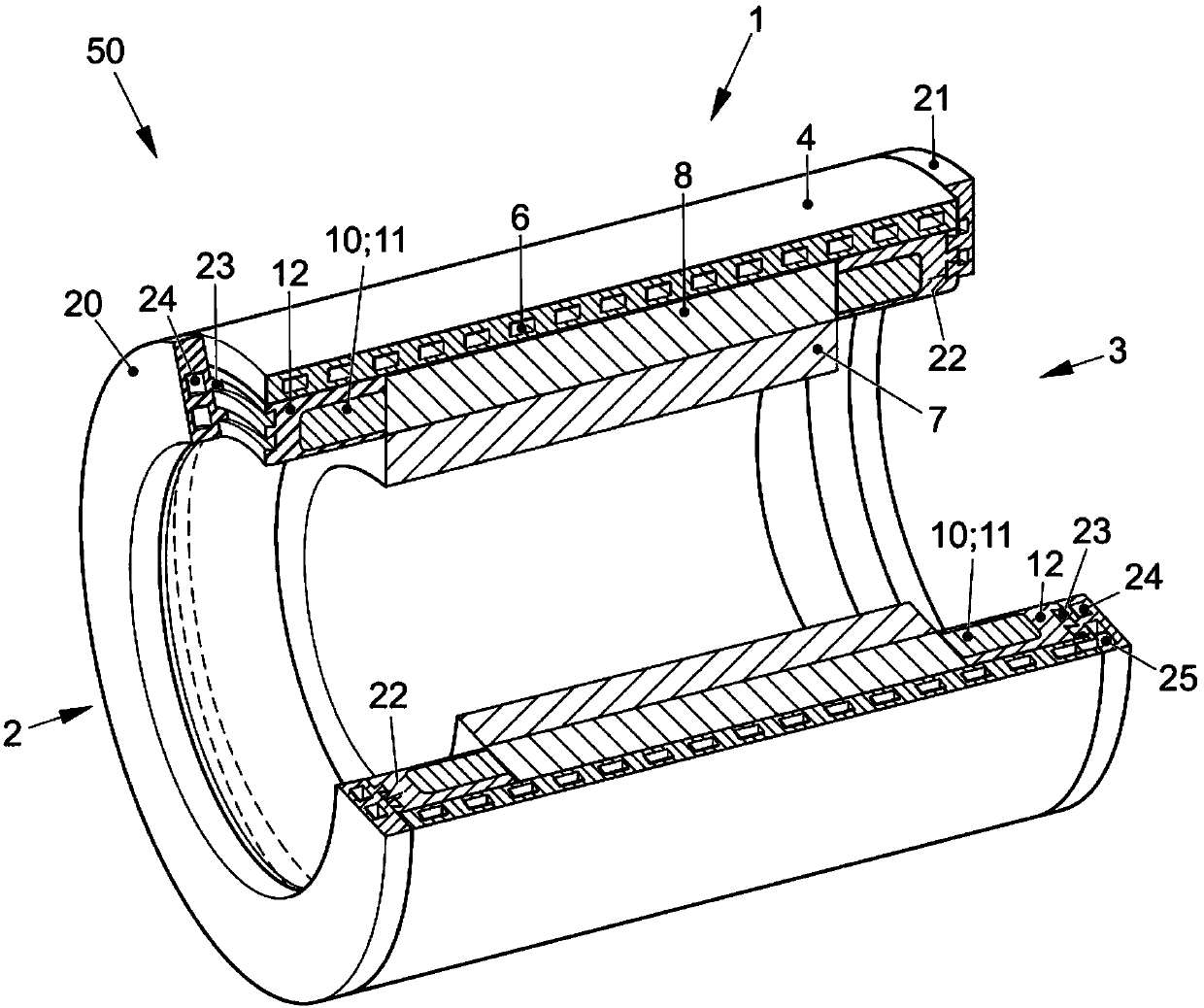

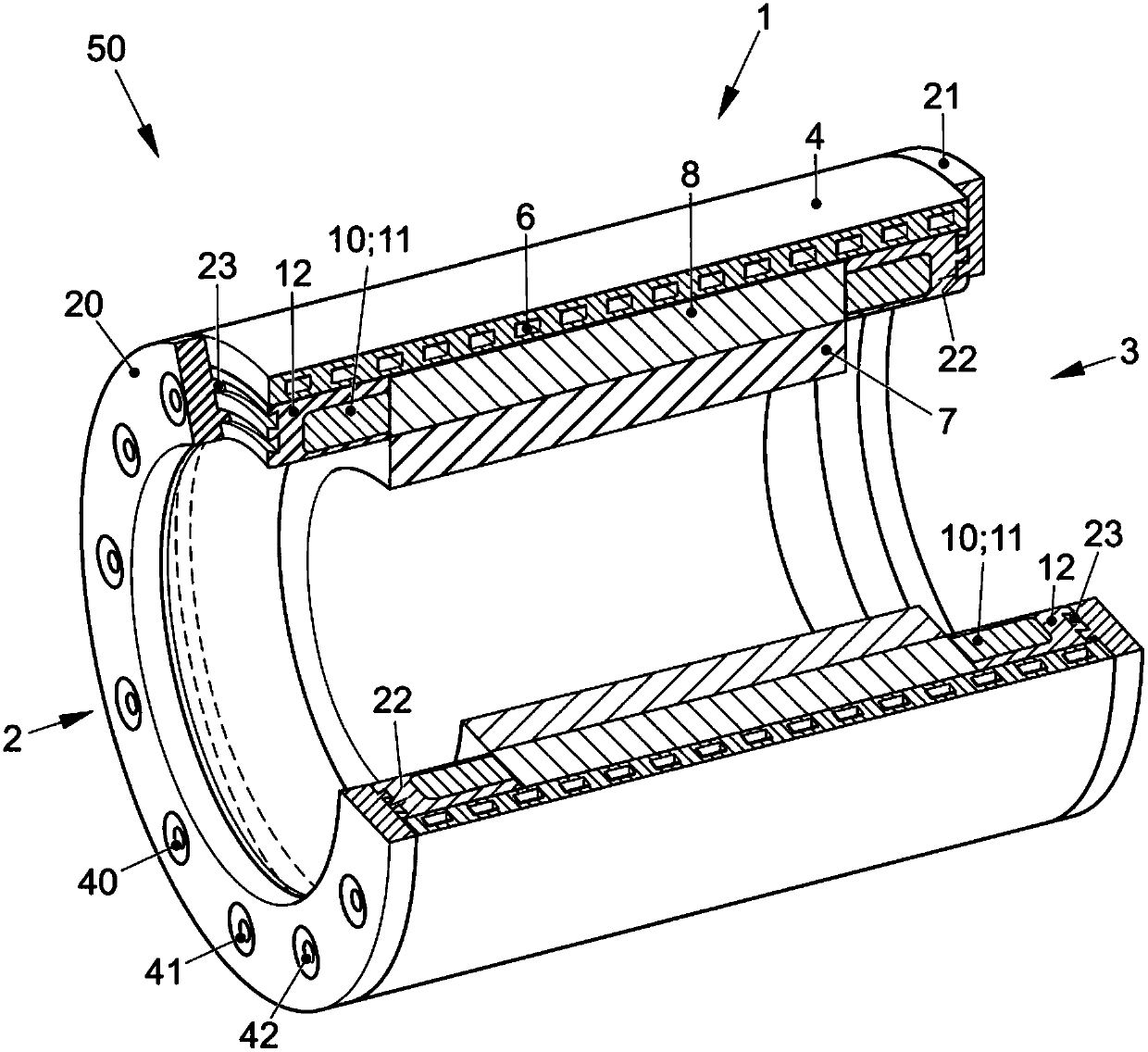

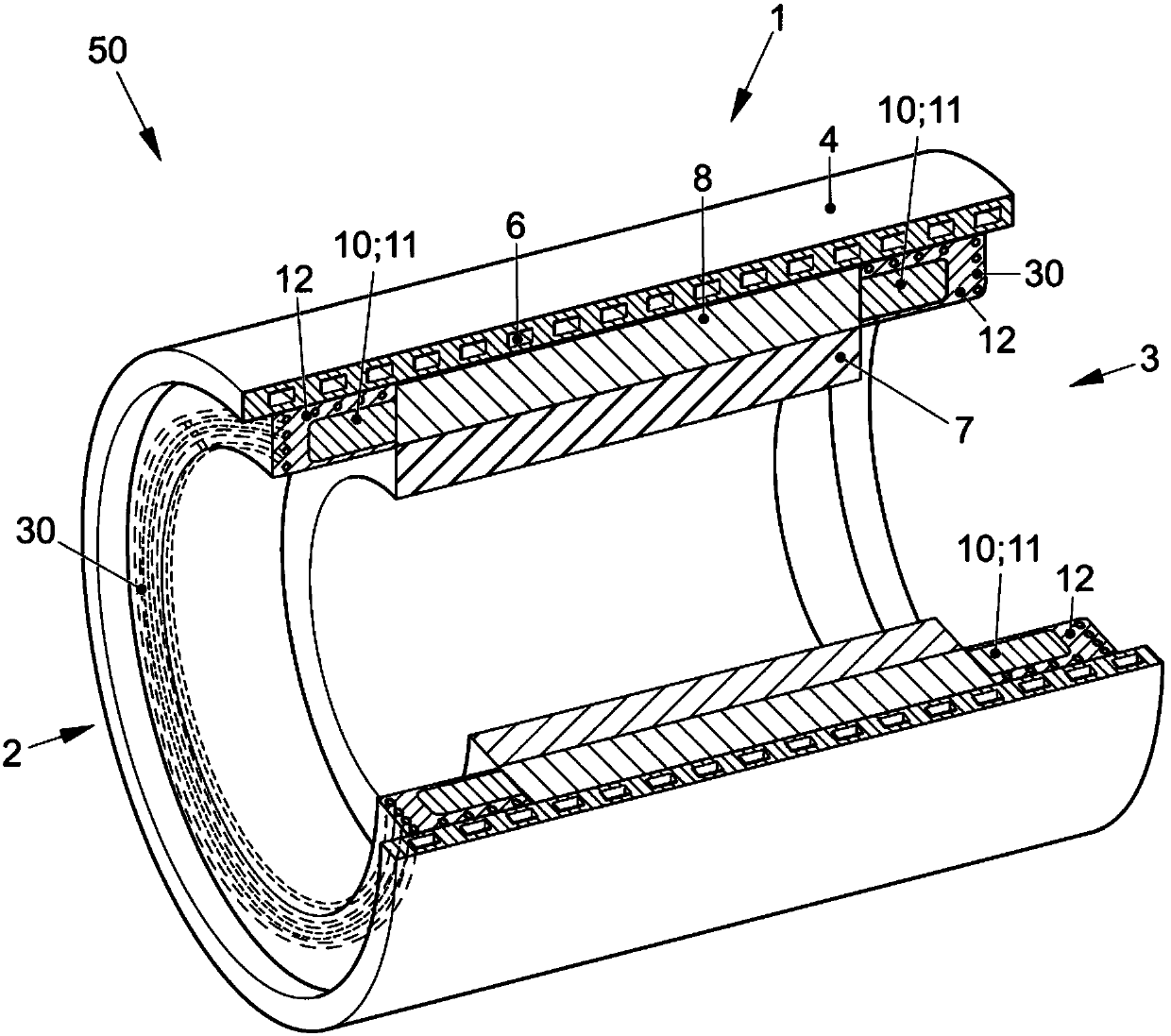

[0034] Figure 1 to Figure 4 Various embodiments of the stator 1 according to the invention of an electric machine 50 according to the invention are shown. In this case, all configurations of the electric machine 50 according to the invention have a rotor 7 which is arranged rotatably supported within the stator pack 8 . The stator pack 8 is surrounded by a stator sleeve 4 , in which cooling lines 6 are respectively arranged for cooling the stator pack 8 . At the first axial end 2 and at the second axial end 3 of the stator pack 8 and thus the stator 1 according to the invention, respectively, a winding 11 is arranged which each form a winding end 10 . Winding end 10 is completely cast by casting compound 12 . For similar or identical elements and components, hereinafter Figure 1 to Figure 4 References can be made to each other. Embodiments of the stator 1 according to the invention of the electric machine 50 according to the invention are in Figure 1 to Figure 4 The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com