Splicing type building template for constructional engineering

A construction formwork and construction engineering technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of building formwork movement, inconvenient concrete pouring and weak connection, etc., to improve stability, The effect of reducing the possibility of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

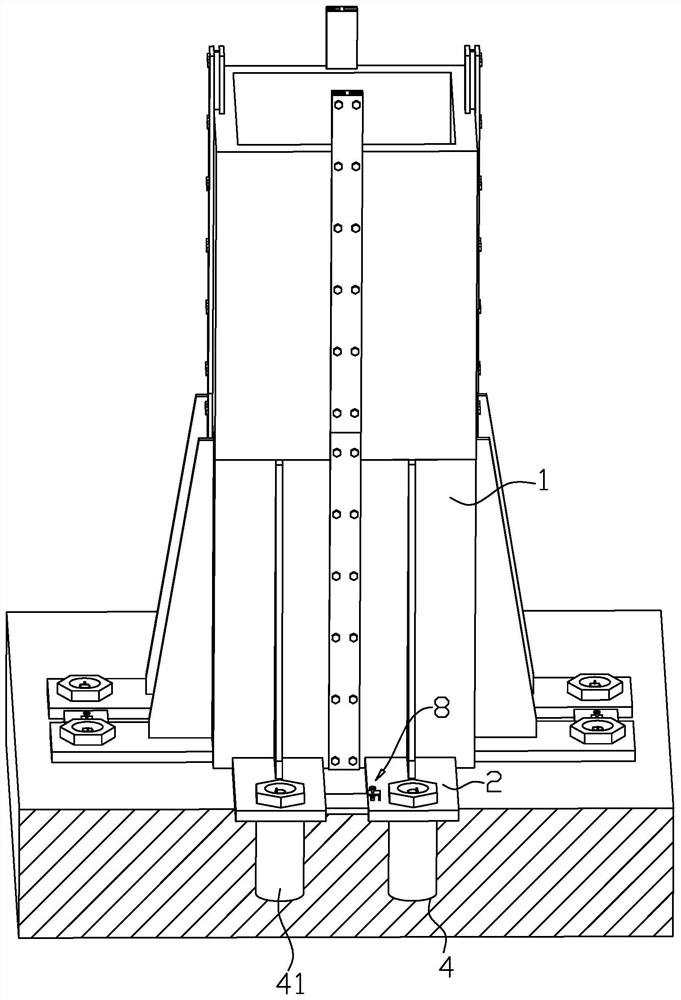

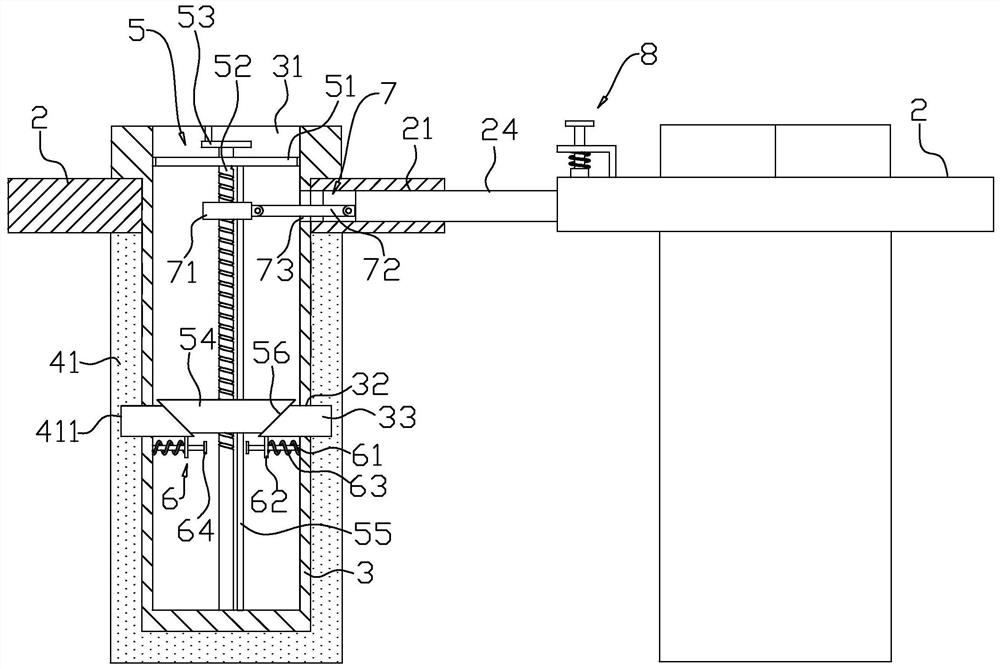

[0030] The invention discloses a spliced building template for construction engineering, such as figure 1 As shown, four formwork bodies 1 are included, and detachable support assemblies are respectively installed at both ends of one side of the formwork body 1, and each set of detachable support assemblies includes a T-shaped support assembly that is vertically slidable and connected to one side of the formwork body 1. plate, a support plate fixed to one side of the T-shaped plate, and a force plate 2 fixed to the bottom of the support plate.

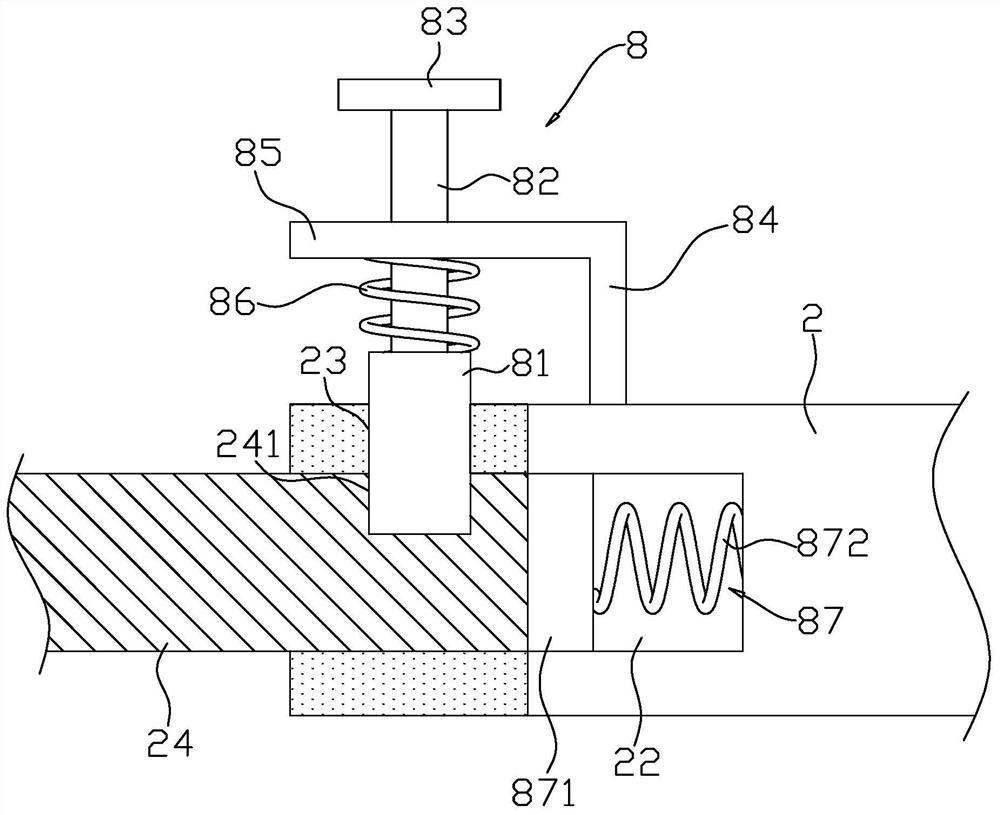

[0031] like figure 1 and figure 2 As shown, the limit plate 3 is vertically fixed on the force plate 2, the limit plate 3 is set through the force plate 2, the part of the limit plate 3 protruding from the force plate 2 is hexagonal, and the limit plate 3 is in the force The bottom part of the plate 2 is cylindrical, and the corresponding limit plate 3 is provided with a first installation groove 4 on the ground. The first install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com