Seepage-proof subway tunnel segment

A technology for tunnel segments and segments, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of reduced anti-seepage effect of segments, corrosion of waterproof strips, and reduced service life of equipment in tunnels, so as to reduce unfavorable The effect of impact, good compression effect, and possibility reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

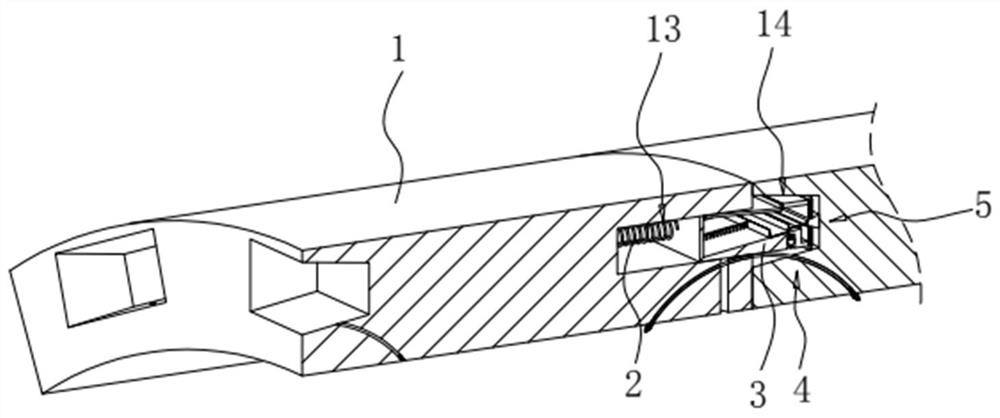

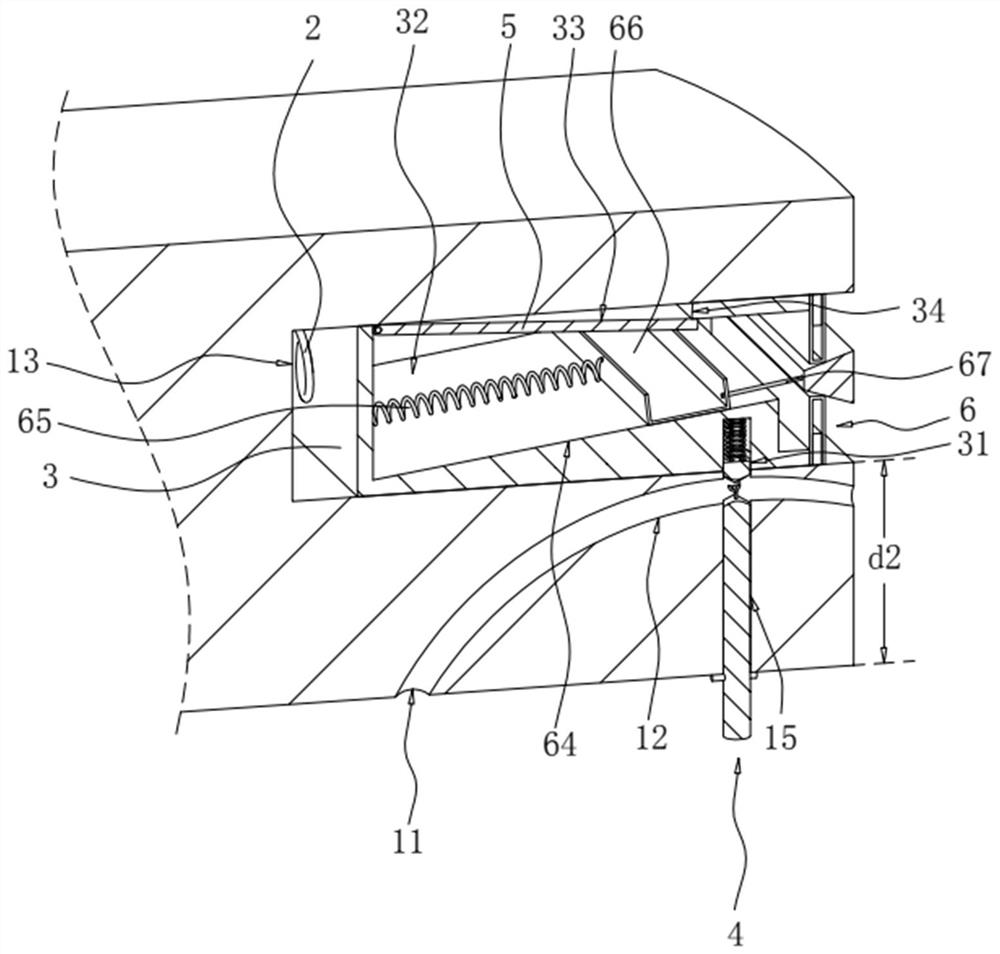

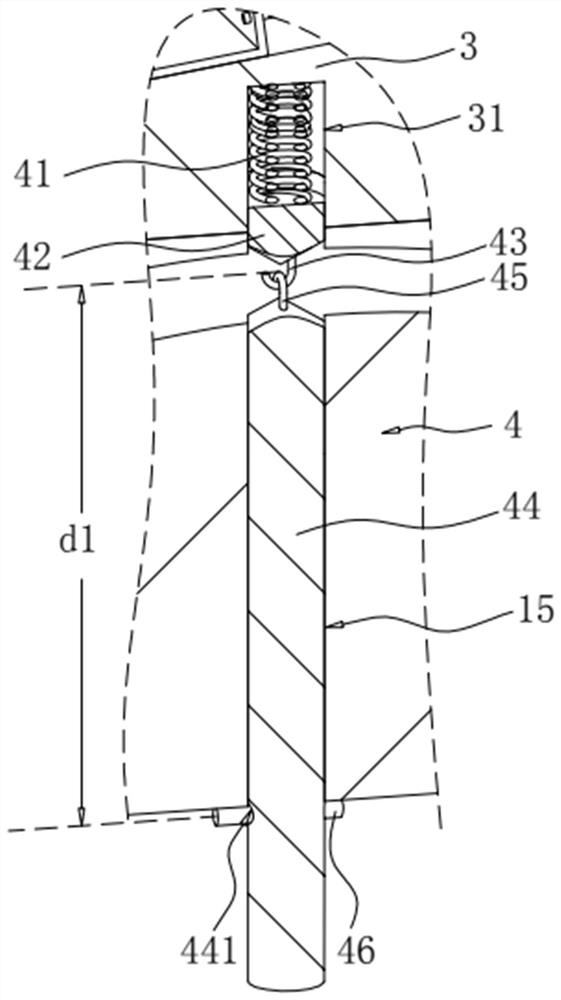

[0040] Combine the following Figure 1-Figure 6 This application will be described in further detail.

[0041] The embodiments of the present application disclose an anti-seepage subway tunnel segment. refer to figure 1 and figure 2 , the segment is installed on the inner wall of the tunnel, the segment includes segment body 1, the direction of segment body 1 along the tunnel axis is the length direction of segment body 1, the span of segment body 1 is the width of segment body 1, The lower surface of the segment body 1 is provided with two groups of insertion holes 11 , the axial direction of the insertion holes 11 is arranged along the height direction of the segment body 1 , and the number of each group of insertion holes 11 is three, and the three are inserted The holes 11 are evenly distributed along the width direction of the segment body 1 . The positions corresponding to the insertion holes 11 on the two fan-shaped side walls of the segment body 1 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com