Packer capable of protecting rubber sleeve for oil field water injection well

A technology of oilfield water injection and packer, which is applied in the direction of sealing/packing, flushing wellbore, wellbore/well parts, etc., and can solve the problems of reducing the service life of the rubber cartridge and not being able to protect the rubber cartridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

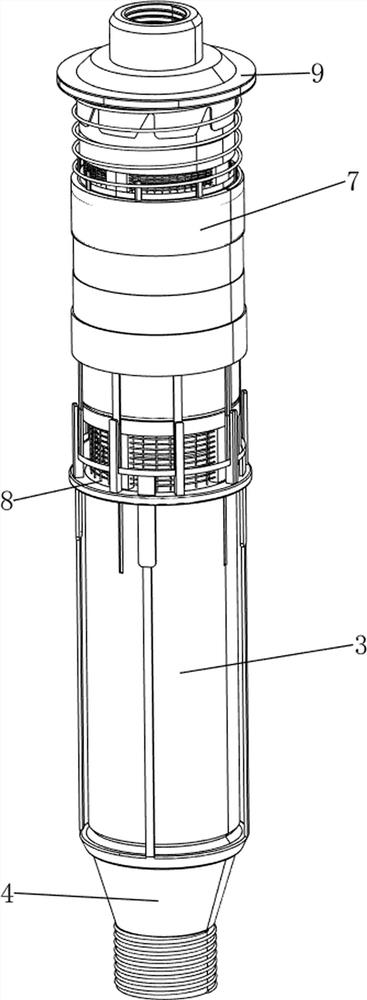

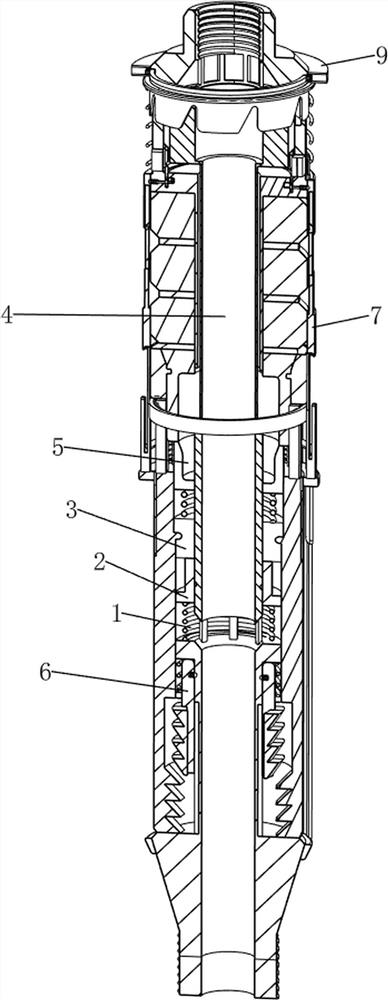

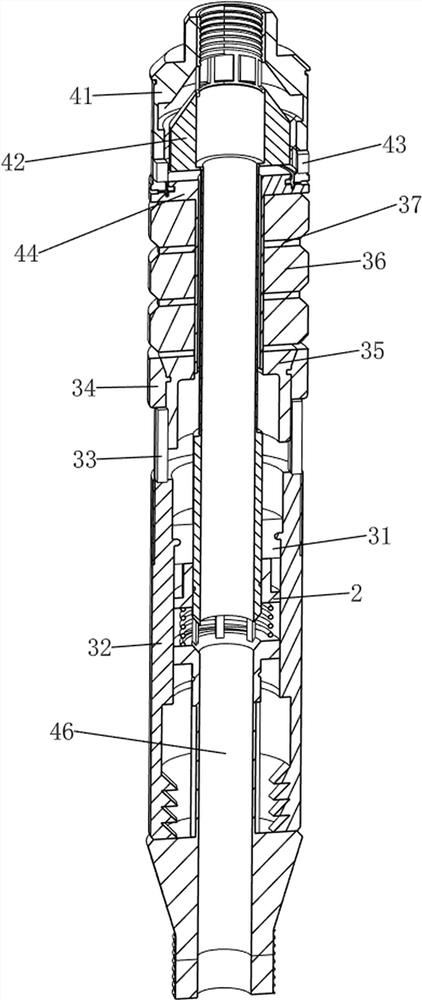

[0048] A packer for oilfield water injection wells that can protect rubber cartridges, such as figure 1 with figure 2 As shown, it includes a first return spring 1, a movable block 2, a setting mechanism 3, an unsealing mechanism 4 and a valve mechanism 5, and also includes a pressure relief mechanism 6 and a protection mechanism 7, and the unsealing mechanism 4 is provided with a setting mechanism. Mechanism 3, the first return spring 1 and the pressure relief mechanism 6, the top of the first return spring 1 is connected with a movable block 2, a valve mechanism 5 is arranged between the unsealing mechanism 4 and the setting mechanism 3, the setting mechanism 3 and the unsealing mechanism A protective mechanism 7 is provided between the mechanisms 4 .

[0049] When the packer needs to be used, first install the packer through the unsealing mechanism 4, after installation, input the high-pressure liquid into the unsealing mechanism 4, and input the high-pressure liquid in t...

Embodiment 2

[0060] On the basis of Example 1, such as Figure 20 with Figure 21 As shown, a filter mechanism 8 is also included, and the filter mechanism 8 includes a brush plate 81, a first filter screen 82 and a second filter screen 83, and a brush plate 81 is connected between the upper parts of the plurality of support plates 74, and each adjacent two The first filter screen 82 is connected between the second connecting block 33 of the first block, and the brush plate 81 is slidably matched with the second connecting block 33. The brush plate 81 brushes the impurities on the first filter screen 82, and every adjacent two pieces A second filter net 83 is connected between the fixing blocks 43 .

[0061] In the process of pouring in and gushing out, the water plays the role of filtering through the first filter screen 82 and the second filter screen 83. When the second connecting block 33 moves upward, it drives the second filter screen 83 to move upward together, and the second filte...

Embodiment 3

[0063] On the basis of Example 2, such as figure 2 , Figure 22 with Figure 23 As shown, it also includes a blocking mechanism 9, the blocking mechanism 9 includes a first blocking plate 91, a third common spring 92, a rotating cylinder 93, a third block 94, a second blocking plate 95 and a push rod 96, and the upper connector The upper part of 41 is connected with a first shielding plate 91, and the upper part of the outer arc surface of the upper connector 41 is connected with multiple groups of third ordinary springs 92 evenly spaced along the circumferential direction, and the third ordinary springs 92 of each group are two sets, and the two of each group A second shielding plate 95 is connected between the third common springs 92, and the second shielding plate 95 is slidingly matched with the first shielding plate 91. The upper part of the upper connector 41 is rotatably connected with a drum 93, and the drum 93 is positioned at the first shielding plate. Below the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com