Scalloped-kidney-shaped sausage machine and use method thereof

A technology of waist sausage and rack, which is applied in the processing of animal intestines, etc., can solve the problems of low automation, low efficiency, and dependence on manual operation, and achieve the effect of convenient operation, simple structure, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

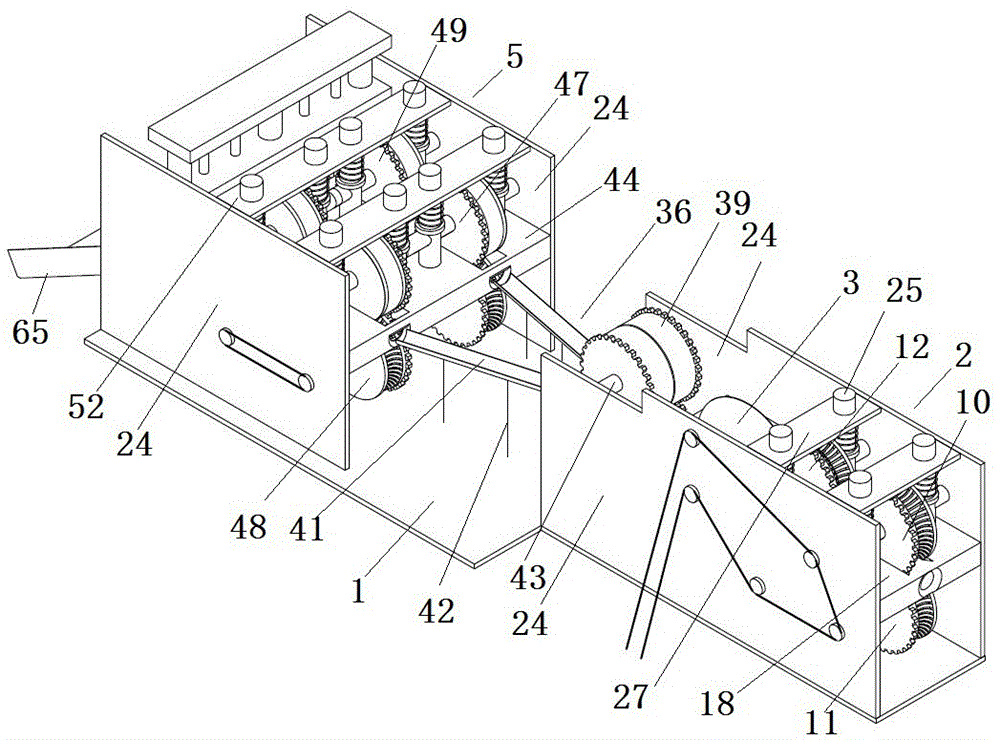

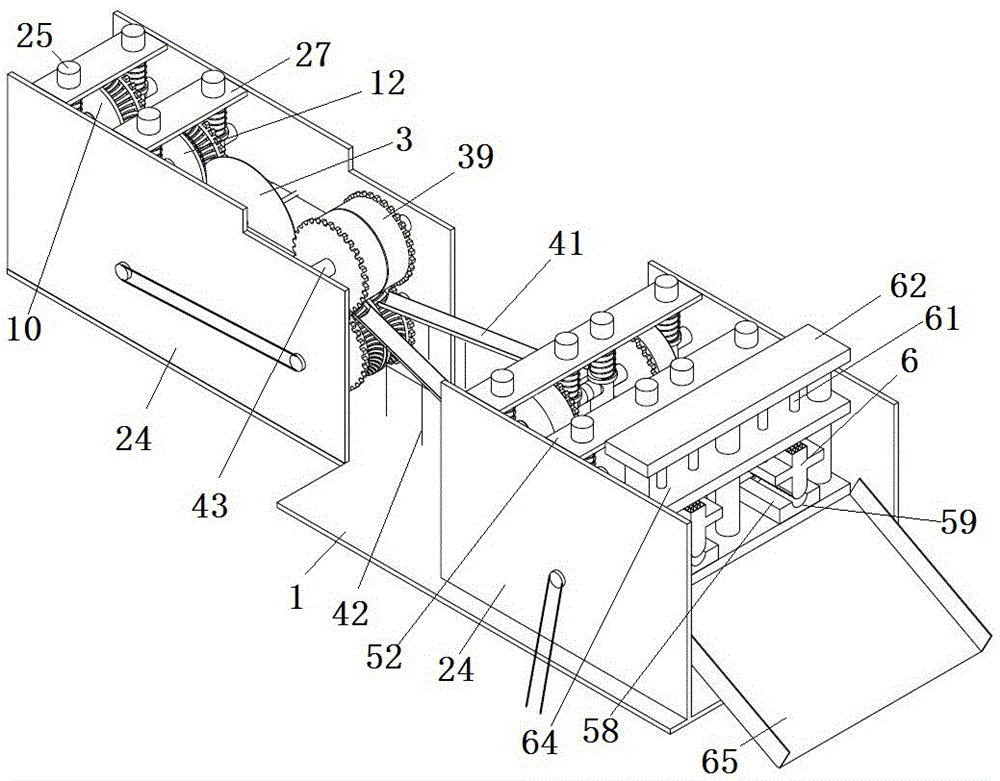

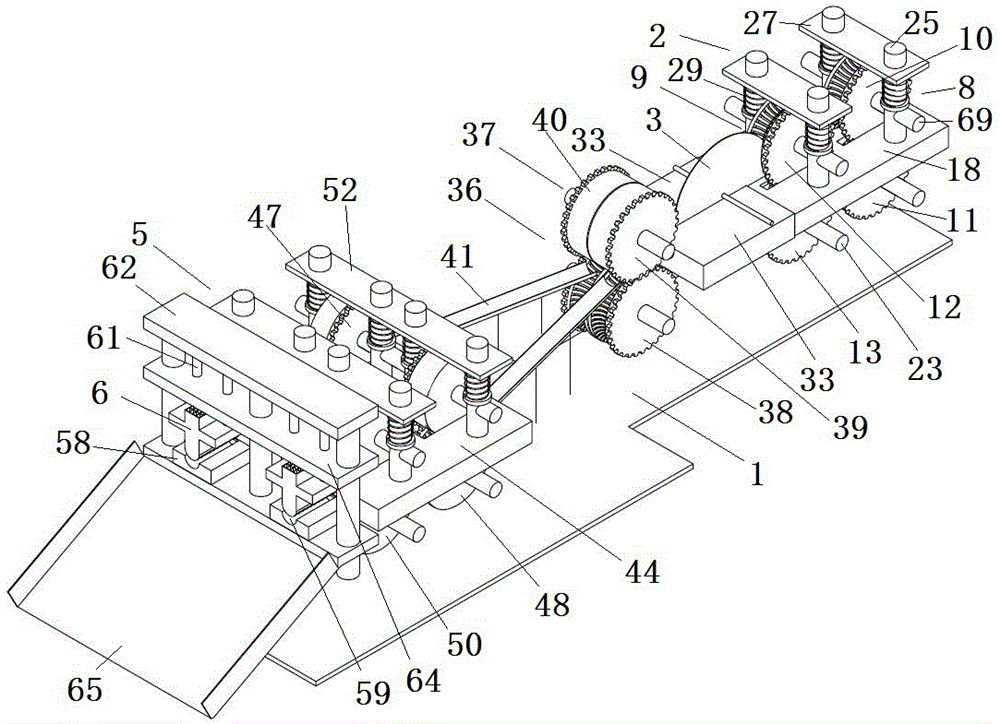

[0048] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0049] Such as Figure 1~29 As shown, a waist sausage machine includes a frame 1, and the frame is provided with a feeding mechanism 2 for conveying round bar-shaped sausage material, and the discharge port of the feeding mechanism is provided with a shaft for feeding the sausage in the axial direction. The material is symmetrically cut into two vertical circular cutterheads 3, and both sides of the vertical circular cutterhead are symmetrically provided with a spiral slideway 4 for turning the vertical cutting surface of each sausage material up to 90°, The outlet of each spiral slideway is provided with a punching mechanism 5, and the punching mechanism includes a vertical punching pattern 6, and inside the vertical punching pattern, there are several lozenge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com