Explosion-proof structure with low equivalent toxic explosive air bag recovery

A technology of explosion-proof structure and explosives, which is used in the storage of ammunition, attack equipment, ammunition, etc., can solve the problem that the explosion-proof structure cannot recover toxic gas products, etc., and achieve the effect of protecting the life, health and safety of personnel, reducing the flow speed, and preventing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

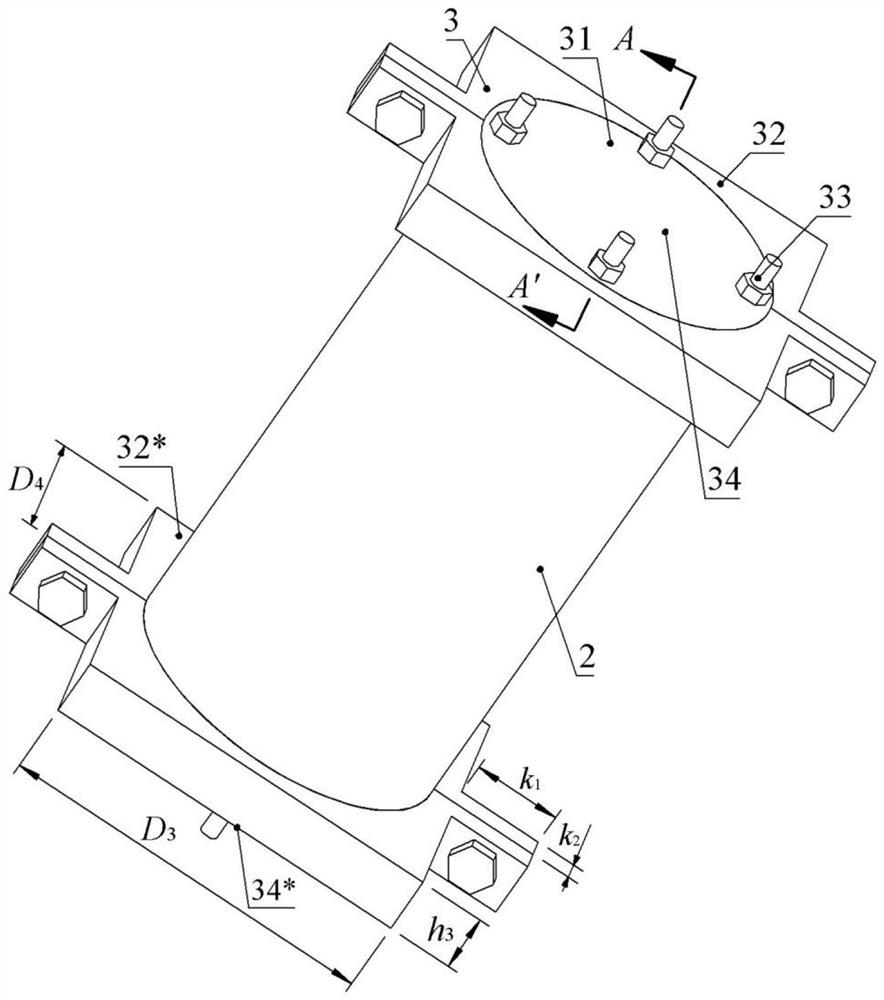

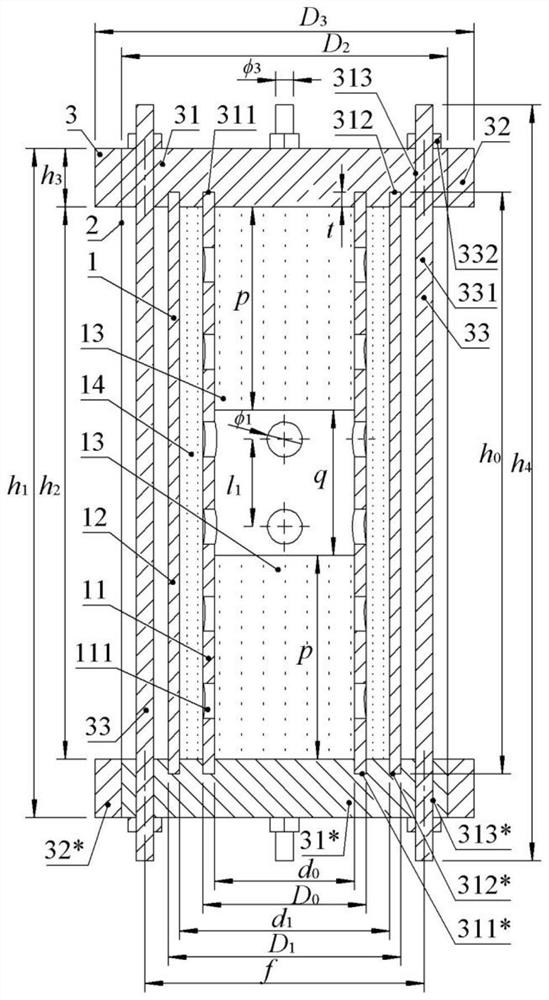

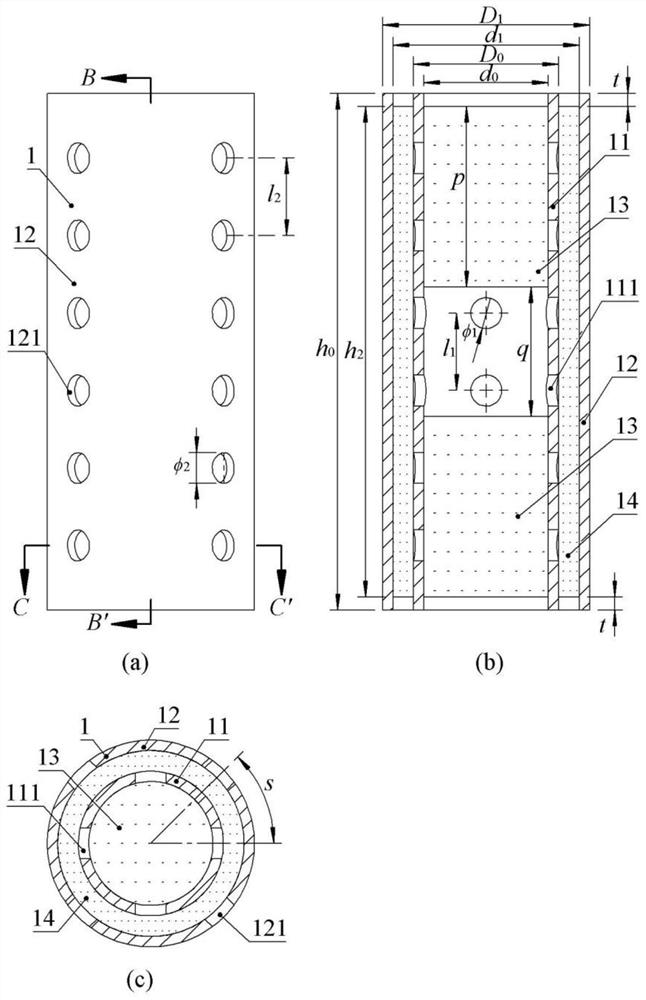

[0031] Such as figure 1 As shown, the low-equivalent toxic explosive air bag recovery type explosion-proof structure of the present invention has a cylinder in the middle and cuboids at both ends. Such as figure 2 As shown, the present invention consists of a buffer layer 1, a cylindrical airbag 2, and a fixing mechanism 3. The buffer layer 1 and the cylindrical airbag 2 are coaxially nested from inside to outside, and the buffer layer 1 and the cylindrical airbag 2 are sandwiched between the fixing mechanism 3. Two end faces (i.e. upper end face 34 and lower end face 34*, see figure 1 )between. The upper end of the buffer layer 1 is stuck in the first inner slot 311 and the first outer slot 312 of the upper end surface 34 of the fixing mechanism 3, and the lower end of the buffer layer 1 is stuck in the second slot of the lower end surface 34* of the fixing mechanism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com