Connector anti-loosening structure for underground high-temperature-resistant and high-voltage-resistant cable

A technology for high-voltage cables and cable joints, applied in the direction of cable joints, etc., can solve the problems of inability to disassemble, loosen, short-circuit, etc., and achieve the effect of improving practicability and improving the ability to prevent loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

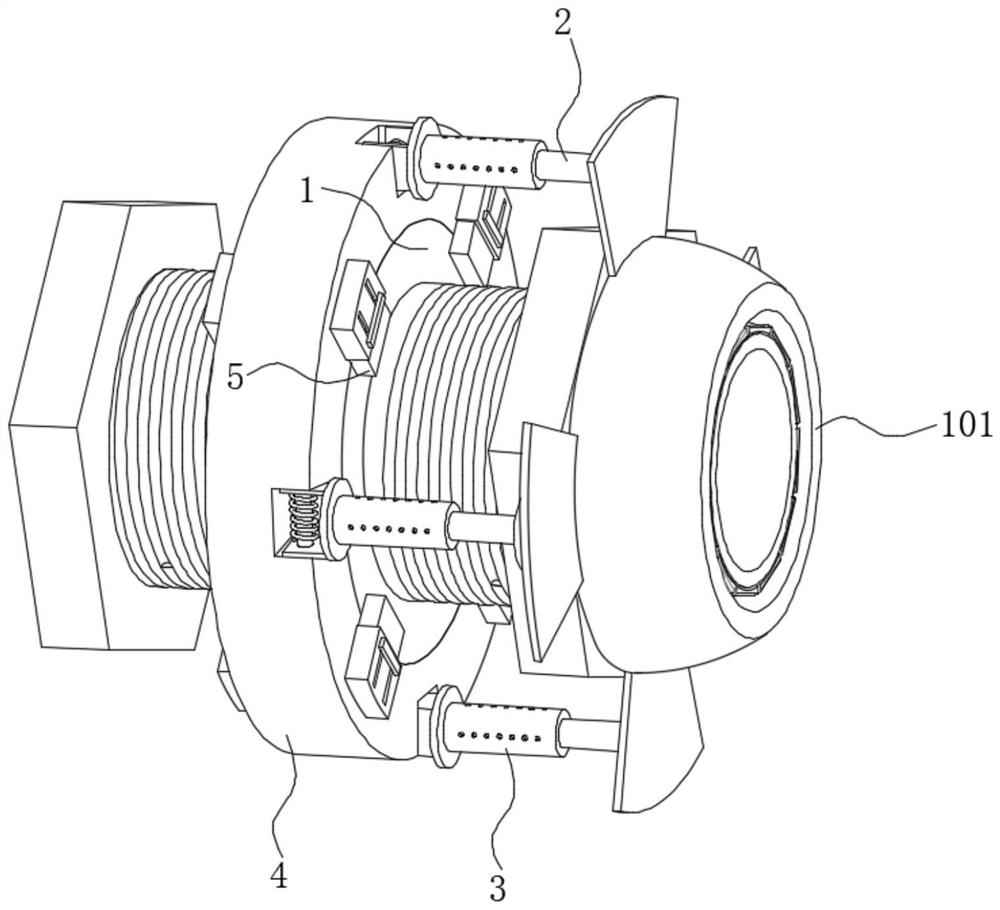

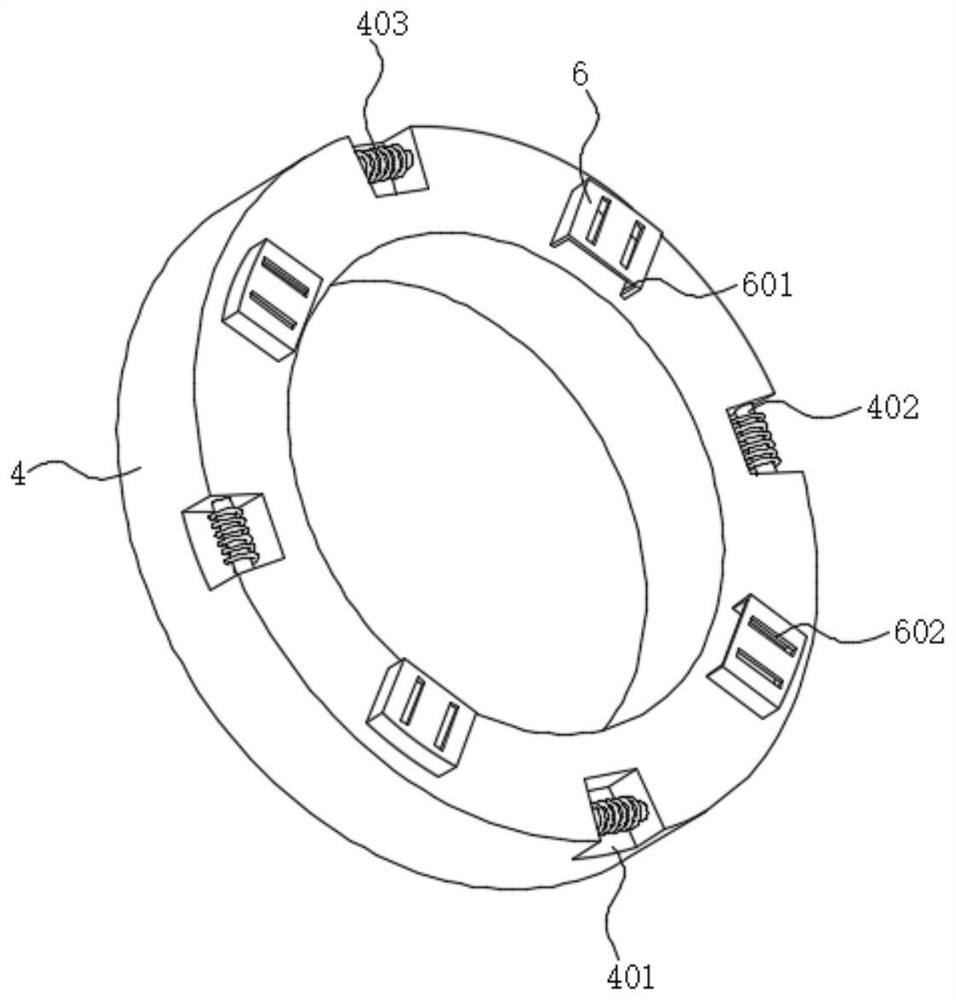

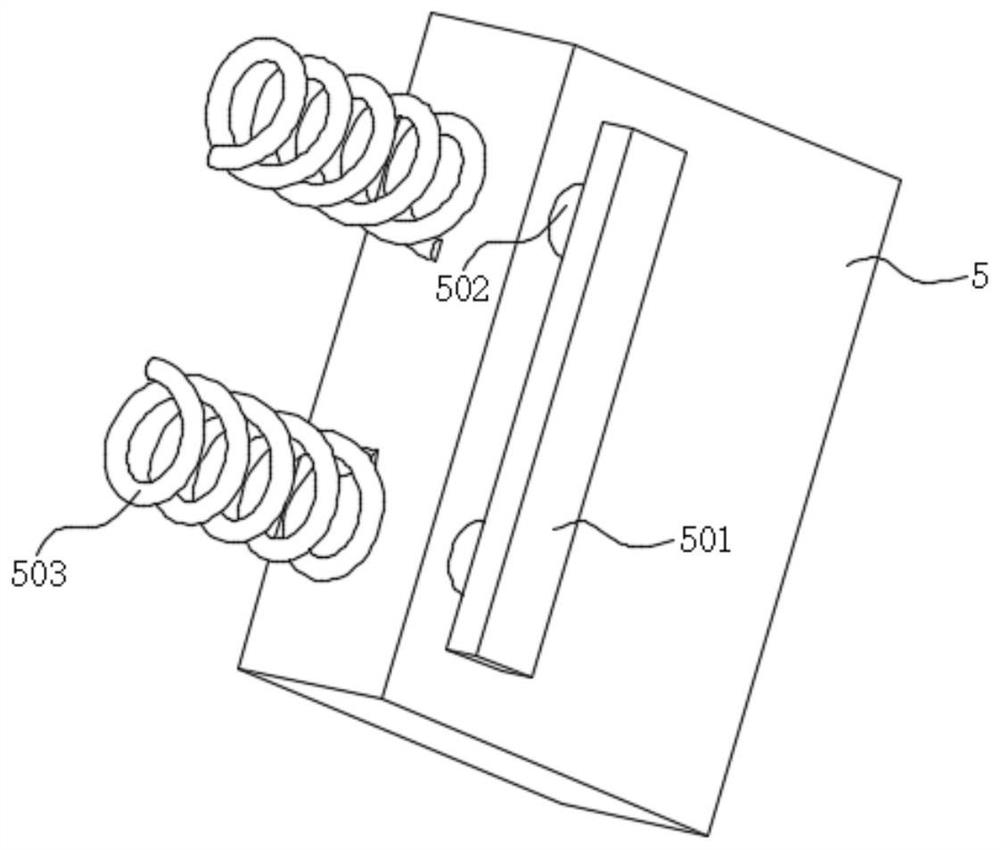

[0037] see Figure 1-6 As shown, the present invention is a joint anti-loosening structure for underground high-temperature and high-voltage cables, including a cable joint body 1, and a mounting ring 4 is set on the surface side wall of the cable joint body 1, and the mounting ring 4 and a locking cap 101 Adjustment columns 3 are arranged between them, and the adjustment columns 3 are distributed in a circular array with four, the right side of the adjustment column 3 is provided with a limit hole 304, and the inner left side of the limit hole 304 is provided with a movable hole 305, and the movable hole The aperture of 305 is larger than the aperture of limit hole 304, and the right side of adjusting column 3 is provided with movable rod 2, and the right end of movable rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com